Horizontal vacuum paddle dryer for sensitive pharmaceutical ingredients

Achieve precise drying and mixing of sensitive materials with a design that ensures cleanability, sterility, and compliance with stringent cGMP and FDA guidelines.

Dries and Mixes Sensitive Materials Efficiently

The COMBER Pharmadry® Series PH 50 – PH 4000 vacuum paddle dryer from HEINKEL Group is designed to tackle the challenges of processing sensitive materials across various industries, including pharmaceuticals and fine chemicals. This equipment excels in drying and mixing operations, using a fully welded agitator design and minimal build depth to ensure excellent cleanability and accessibility. With a processing capacity between 50 to 4,000 liters, it supports both batch and pilot operations, making it ideal for products like APIs, protein isolates, and metallic pigments.

The Pharmadry® meets stringent cGMP and FDA guidelines, including options for aseptic and steam sterilizable versions. It boasts a double mechanical seal, which is externally interchangeable, enhancing ease of maintenance. Constructed from stainless steels and high-performance alloys like Hastelloy C 22, it is suitable for environments requiring high corrosion resistance. The equipment’s PLC-controlled system allows seamless integration with existing lines, enhancing operational efficiency through automation. A built-in CIP system ensures contamination-free cleaning, while optional features like a vacuum system with condenser further optimize energy use.

Benefits

- Enhances product purity with efficient drying and mixing tailored for sensitive materials.

- Ensures compliance with industry standards, reducing regulatory risks.

- Simplifies cleaning and maintenance through a fully welded, CIP-compatible design.

- Minimizes operational disruptions with robust, externally interchangeable mechanical seals.

- Accommodates diverse materials with corrosion-resistant alloy options.

- Applications

- Surface coating, Fine chemicals, Chemical products, Metal recycling, Food products, Pharmaceuticals

- End products

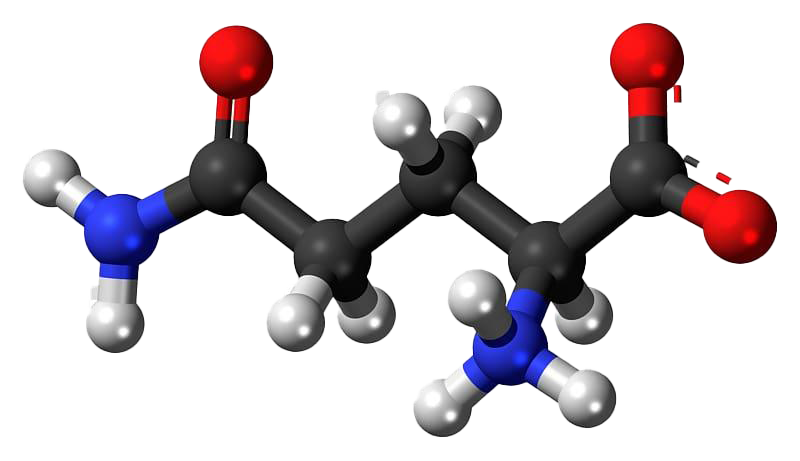

- Amino acids, Flavor enhancers, Powdered milk, Metal powders, Agricultural chemicals, Active pharmaceutical ingredients (apis), Metallic pigments, Protein isolates, Excipients, Instant coffee, Specialty polymers, Vitamin e supplements

- Steps before

- Purification, Emulsification, Grinding

- Steps after

- Sterilization, Packing

- Input ingredients

- freely flowing pharmaceutical ingredients, fine chemicals

- Output ingredients

- dried pharmaceutical ingredients, dried fine chemicals

- Market info

- Heinkel (Comber) is renowned for manufacturing industrial engineered-to-order equipment, specializing in filtration, centrifugal, and mixing solutions. They are recognized for their precision engineering, quality, and ability to tailor solutions for pharmaceutical and chemical industries.

- Usable volume

- 50 – 4, 000 liters

- Design temperature

- -10 to 150°C (14 to 302°F)

- Design pressure

- -1 to +6 barg (FV to 90 psig)

- Material

- Stainless steels, Hastelloy C 22, Alloy 59, Titanium

- Sealing materials

- PTFE gaskets, O-Rings in FFKM or FEP encapsulated

- Heated areas

- All product wetted components

- Cycle time

- Minimal drying times

- Automation

- PLC-controlled

- Cleaning method

- CIP systems, steam sterilizable

- Agitator type

- Paddle, entirely welded design

- Batch vs. continuous operation

- Batch

- CIP/SIP

- CIP systems with simple validation

- Automation level

- PLC with HMI interface

- Cleaning method

- Excellent cleanability using CIP systems

- Changeover time

- Minimal due to good accessibility

- Working mechanism

- Vacuum paddle dryer

- Cleanability

- Excellent with CIP systems

- Corrosive resistance (e.g. acids)

- Stainless steels, Nickel based alloys

- Biological compatibility

- FDA and cGMP compliant materials

- Abrasion resistance

- Good with Hastelloy C 22 or Alloy 59

- Agitator design

- Entirely welded, without bolts

- Agitator support

- Supported at the rear

- Build depth

- Minimal

- Accessibility

- Very good for inspection and cleaning

- Design pressure

- -1 to +6 barg (FV to 90 psig)

- Design temperature

- -10 to 150°C (14 to 302°F)

- Usable volume

- 50 – 4, 000 liters

- Material options

- Stainless steels, Nickel alloys, Titanium

- Footprint

- Compact

- Seal type

- Double mechanical, externally interchangeable

- Heating

- All product wetted components

- Control panel type

- HMI with touch screen

- Integration possibilities

- Interface for DCS

- Sealing type

- Double mechanical seal, externally interchangeable

- Material options

- Stainless steels, Nickel based alloys, Titanium

- Agitator design

- Entirely welded, no bolts, pockets, rounded edges

- Cleaning systems

- CIP systems

- Process separation

- Separating wall between process and mechanical areas