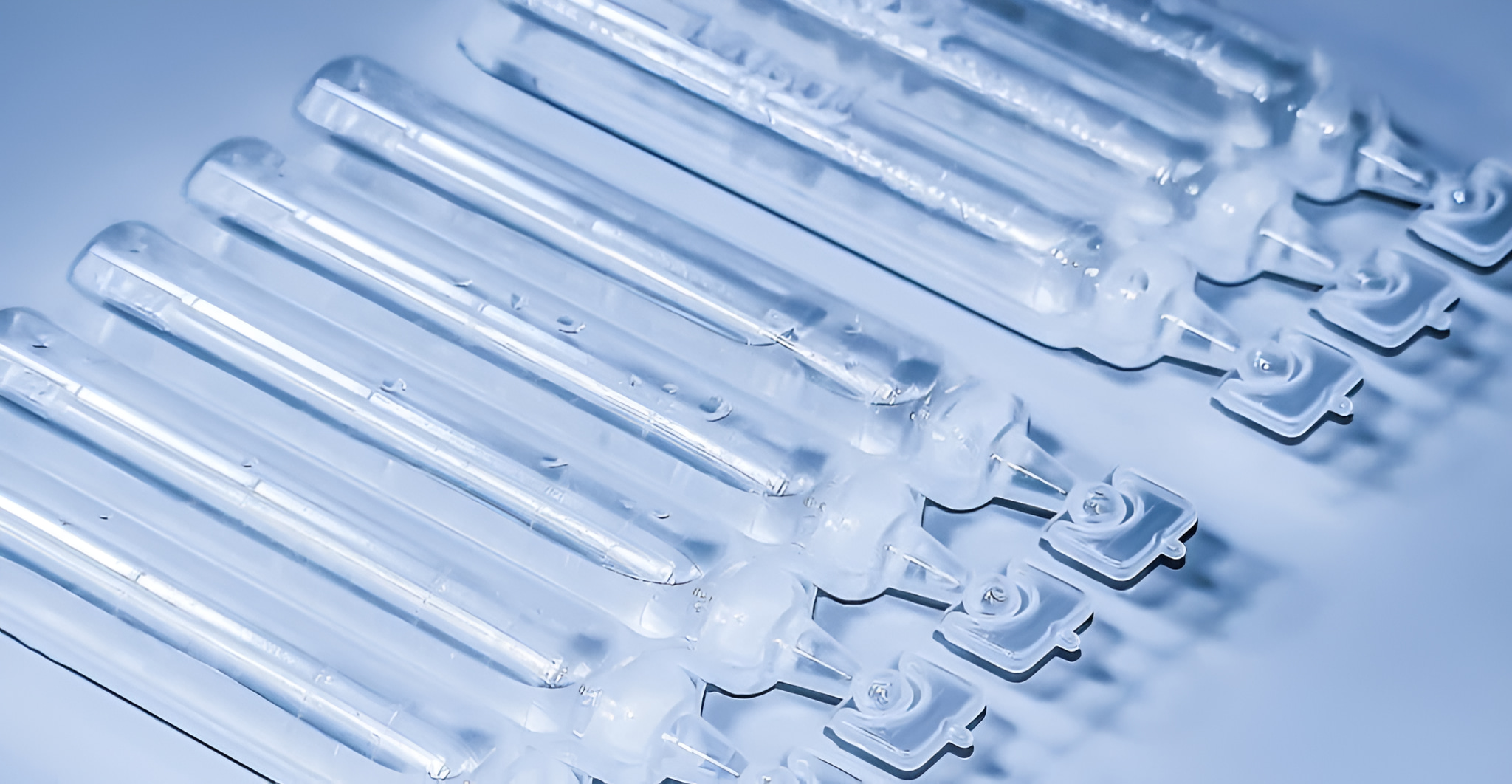

Aseptic vials filling and capping

Ensure precise vial capping and sealing for liquid pharmaceuticals with advanced aseptic processing, vital for maintaining product sterility and integrity throughout production.

Caps, Seals, and Inspects Aseptic Vial Fillings

The ML670 from Marchesini Group is a rotary vial capping machine specifically designed for aseptic processing of small volume parenterals. This machine distinguishes itself with its ability to execute precise alu-sealing with single blade technology, complemented by controlled vial spinning via brush-less motors. It’s engineered to seamlessly integrate under LAF and oRABS environments, crucial for maintaining aseptic conditions. Ideal for pharmaceuticals like monoclonal antibody injections and insulin vials, the ML670 ensures reliable capping and sealing. With a throughput of up to 24,000 pieces per hour, it incorporates automatic capping pressure control, stopper presence detection, and rejection of faulty vials. Its compact design includes a pre-feeder and cap sorting system, facilitating straightforward integration into production lines. All operations are automatically regulated, enhancing efficiency and reducing labor requirements, while meeting stringent pharmaceutical industry standards.

Benefits

- Maximizes production efficiency with a capacity of up to 24,000 vials per hour.

- Ensures sterile integrity with precise, particle-free sealing in aseptic environments.

- Reduces inspection labor with automatic faulty vial detection and rejection.

- Enhances operation flexibility with seamless integration under LAF and oRABS conditions.

- Minimizes space usage with its compact onboard pre-feeder and cap sorting system.

- Applications

- Biopharmaceuticals, Small volume parenterals, Liquid formulations, Pharmaceuticals

- End products

- Insulin vials, Monoclonal antibody injections, Intravenous antibiotics, Ophthalmic solutions, Pediatric liquid medication, Liposome encapsulated drugs, Analgesic liquid formulations, Vaccine doses

- Steps before

- Washing and Sterilizing, Ampoules Filling and Sealing

- Steps after

- Inspection for Glass Containers, Leak Test, Labelling and Serialization

- Input ingredients

- vials, alu-caps, stoppers

- Output ingredients

- capped vials, sealed vials, faulty vials rejection

- Market info

- Marchesini is renowned for manufacturing high-quality packaging machinery for the pharmaceutical and cosmetics industries, offering innovative, customized solutions with advanced automation and technology.

- Automation

- Automatic capping pressure control

- Automation

- Automatic stopper presence and position control

- Automation

- Automatic alu-cap presence control

- Capacity

- Up to 24.000 pieces/h

- Vial Compatibility

- 2R / 100 ml vials

- Alu-sealing technology

- No-particle based on single blade and controlled vial spinning system

- Motor Type

- Brush-less motors

- Integration Capability

- Easy integration under LAF and oRABS

- Automation level

- Automatic with PLC control

- Integration under LAF and oRABS

- Easy integration

- No-particle alu-sealing technology

- Single blade and controlled vial spinning system

- Automatic capping pressure control

- Yes

- Automatic stopper presence and position control

- Yes

- Automatic alu-cap presence control

- Yes

- Automatic rejection of faulty vials

- Yes

- Alu-cap pre-feeder and sorting system

- Integrated and compact

- Output capacity

- Up to 24, 000 pieces/h

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Vials

- Machine footprint

- Compact

- Vial spinning system

- Controlled by brush-less motors

- Integration

- Under LAF and oRABS

- Integration possibilities

- Easy integration under LAF and oRABS

- Control panel type

- Brush-less motors control for vial spinning

- Footprint

- Compact arrangement

- Alu-cap pre-feeder and sorting system

- Integrated on board