Sterile robotic filling for ready-to-use vials and syringes

Achieve precise and contamination-free filling for biopharmaceutical vials and syringes with this advanced system, ensuring product integrity through seamless isolator integration and versatile container handling.

Fills and Stoppers Sterile Vials and Syringes

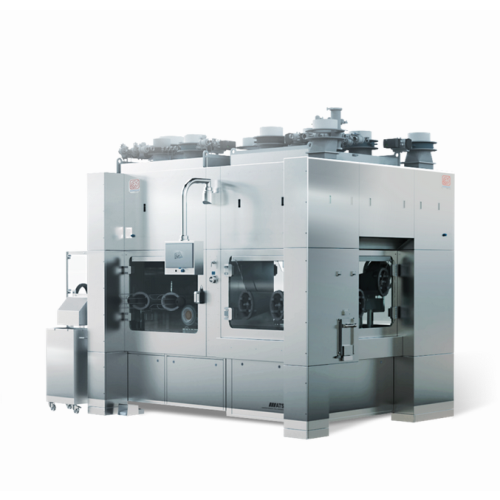

The Flex-Line™ from Comecer integrates cutting-edge robotic technology with modular isolator systems to deliver an unparalleled aseptic filling solution. Designed for biopharmaceuticals, vaccines, and advanced therapies, the machine excels in precise filling and stoppering of sterile vials and syringes. It employs a robotic handling system to eliminate glass-to-glass contact and incorporates peristaltic or piston pump fillers based on specific production needs. Capable of seamlessly aligning with existing production lines, Flex-Line™ supports both semi-automatic and automatic operations, catering to capacities of up to 2,500 syringes or 2,000 vials per hour. Its integrated VPHP decontamination and ISO 5/Grade A laminar flow ensure rigorous compliance with cGMP standards. With PLC and HMI controls, the system also offers real-time monitoring, facilitating rapid adjustments and operational efficiency. The compact design is engineered for minimized footprint and maximum precision, reducing contamination risks and enhancing overall productivity of pilot-scale and research production environments. Flex-Line™ not only meets but often exceeds industry benchmarks for quality and safety, offering extensive customization options to adapt to diverse processing requirements.

Benefits

- Enhances aseptic conditions, minimizing contamination risks in pharmaceutical production.

- Increases operational efficiency with automation that handles up to 2,500 units per hour.

- Reduces human intervention, thereby lowering labor costs and manual error.

- Ensures regulatory compliance with cGMP standards and ISO 5 air quality.

- Allows flexible production with fast changeovers between different container types and sizes.

- Applications

- Gene therapy products, Liquid formulations, Vaccines, Cell, Pharmaceutical syringes, Biopharmaceuticals, Pharmaceutical vials

- End products

- Monoclonal antibody vials, Biopharmaceutical suspensions, Pre-filled insulin syringes, Lyophilized drug vials, Gene therapy vector vials, Antiviral pharmaceutical syringes, Sterile injectable vaccines, Cell-based therapy doses, Biologic drug products, Chemotherapy drug vials

- Steps before

- Decontamination, Aseptic Preparation, Material Loading

- Steps after

- Stoppering, Check Weighing, Sterilization, Nitrogen Purging, Sealing

- Input ingredients

- ready-to-use vials, prefilled syringes, nested syringes, nested vials, liquid products, lyophilized products, nests, tubs

- Output ingredients

- sterile filled vials, sterile prefilled syringes, aseptic vials, aseptic pre-filled syringes

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Automation

- Fully automatic or semi-automatic

- Capacity

- 2500 syringes/hour, 2000 vials/hour

- Filling accuracy

- High filling accuracy by peristaltic pump

- Filling method

- Peristaltic or Volumetric piston pumps

- Control System

- Panel PC HMI compliant with CFR21 Part11 and Data Integrity

- Air Quality

- ISO5 / Grade A (EU-GMP)

- Compact footprint

- Yes

- Decontamination system

- Integrated VPHP system

- Air Flow

- Full Laminar Air Flow

- Nitrogen purging

- Before, After filling

- Container type

- Nested vials and Pre-filled Syringes

- Particle counter

- Included

- Microbiological sampler

- Included

- Leak Test

- Automatic for Chambers

- HEPA Filtration

- HEPA H14 absolute filter

- Automation level

- Fully Automatic / Semi-Automatic

- Batch vs. continuous operation

- Batch / Semi-Batch

- Changeover time

- Minimal

- Cleaning method

- VPHP Decontamination

- CIP/SIP

- VPHP Sterilization

- Energy efficiency

- Optimized for minimal human intervention

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- CGMP Standards

- Compliant

- ISO 10648-2

- Class 3

- ISO 9001

- Compliant

- ISO 13485

- Compliant

- ISO 45001

- Compliant

- ISO 14001

- Compliant

- ISO 50001

- Compliant

- Machine footprint

- Compact footprint

- Control panel type

- Panel PC HMI Control System

- Control panel type

- Panel PC HMI Control System compliant with CFR21 Part11

- Integration possibilities

- Integrated with isolator

- Filling system type

- Peristaltic or Volumetric piston pumps

- Robotic handling configurations

- Multiple possible configurations for different production needs

- Decontamination system

- Integrated VPHP generator with distribution pipes

- Process control and documentation

- HMI with SCADA interface available

- Sterile Transfer Ports

- RTP Rapid Transfer Port or Sterile Liquid Transfer port

- Glove Testing

- Speedy Glove– Automatic glove tester