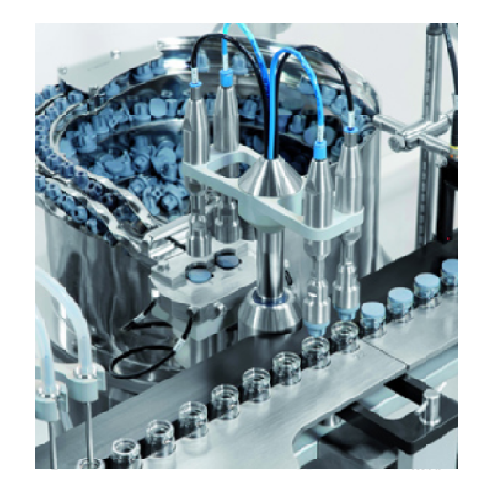

Automatic linear filling stoppering system for large volume vials

Ensure precise vial filling and secure sealing with a high-speed system designed for aseptic conditions, streamlining your process from filling to inspection, while minimizing contamination risk.

Fills, Stopers, and Caps Vials Efficiently

The LFS-8 Phoebus from Siempharma is a linear filling and stoppering machine designed for seamless integration into aseptic production lines in pharmaceutical, nutraceutical, and cosmetic sectors. It efficiently handles liquid and lyophilized products in vial formats up to 500 ml, with two machine cycles capable of processing vials up to 1000 ml. The LFS-8 utilizes an intermittent motion system with format-based scroll or carrying rake for precise vial transport, synchronizing movements to eliminate nozzle adjustments. Its compact design features an integrated alu-capping station, though optional installation on a separate RC-100/200 LADON is available. Dosage is managed by volumetric or peristaltic pumps, ensuring accurate filling. A rubber stopper system allows for complete or partial stoppering, with a built-in rejection device for faulty vials. Constructed from AISI 304 stainless steel and compliant with GMP standards, the machine is designed for easy cleaning and compliant with Industry 4.0 standards. User-friendly HMI ensures quick configuration and operation, while compliance with CFR21 part 11 / EU ANNEX 11 facilitates regulatory adherence.

Benefits

- Enhances production efficiency by precisely filling and stoppering with minimal manual intervention.

- Reduces contamination risk through aseptic integration, ensuring high product safety standards.

- Increases flexibility by handling a wide range of vial sizes and liquid types seamlessly.

- Minimizes operational costs with a built-in faulty vial rejection system to prevent waste.

- Facilitates regulatory compliance with GMP and Industry 4.0 standards.

- Applications

- Pharmaceutical solutions, Liquid formulations, Nutraceutical solutions

- End products

- Insulin vials, Reconstituted antibiotic liquids, Vitamin supplement vials, Essential oil vials, Protein supplement liquids, Herbal extract vials, Probiotic liquid suspensions, Vaccine vials, Allergy medication vials, Lyophilized pharmaceutical powders

- Steps before

- Aseptic preparation, Vial cleaning, Liquid formulation

- Steps after

- Capping, Quality control, Packing

- Input ingredients

- vials, liquid products, lyophilized products, rubber stoppers

- Output ingredients

- filled vials, stoppered vials, capped vials

- Market info

- Filling volume

- Up to 500 ml

- Handling capacity

- Vials up to 1000 ml

- Dosing groups

- Up to 8 groups

- Automation

- PLC-controlled

- Material

- AISI 304 stainless steel

- Safety

- Safety guards with interlock switches

- Cleaning

- Designed for easy cleaning

- Regulatory compliance

- CFR21 part 11 / EU ANNEX 11 ready

- Industry Standard

- Industry 4.0 compliant

- Vial transport

- Format-based scroll or carrying rake

- Working mechanism

- Linear intermittent motion

- Integrated steps

- Filling and stoppering

- CIP/SIP

- CIP / Manual

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Batch

- Changeover time

- Easy change size parts

- Cleaning method

- Easy cleaning

- Biological compatibility

- FDA approved materials

- Cleanability

- Easy to clean design

- Corrosive resistance (e.g. acids)

- AISI 304 stainless steel

- Abrasion resistance

- High durability components

- Container type

- Vials

- Filling purpose

- Liquid or lyophilized products

- Vial size/volume

- Small up to large volume vials (500 ml)

- Machine footprint

- Compact design with stainless steel frame

- Frame material

- AISI 304 stainless steel

- Screens/doors

- Transparent with safety interlock switches

- Contact material

- FDA or other approved materials

- Control panel type

- Touch Screen HMI

- Integration possibilities

- oRABS / cRABS / Isolator

- Nozzle adjustment

- Eliminated need for adjustment

- Dosing groups

- Up to 8 dosing groups

- Handling capacity

- Up to 1000 ml vials