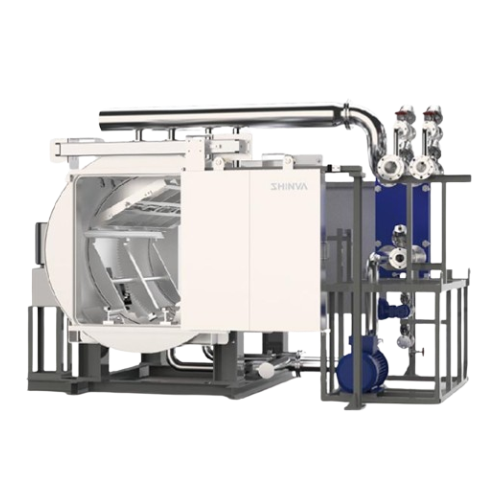

Moist heat sterilizer for liquid preparation

Ensure precise sterilization of pharmaceutical liquids and injectable biologics with advanced moisture heat technology that minimizes energy consumption while maintaining product integrity and safety.

Sterilizes and Ensures Integrity of Liquid Pharmaceuticals

The Moist Heat Sterilizer for Liquid Pharmaceutical Preparation from SHINVA is designed for pharmaceutical and biotechnology applications, offering a reliable solution for sterilizing a variety of liquid products. Utilizing a dynamic super-heated water or air-steam mixture, this sterilizer ensures thorough sterilization while preserving the integrity of sensitive liquid medicines like injectable biologics, oral liquids, and insulin prefilled syringes.

With advanced automation, these sterilizers feature rapid heating and cooling cycles, and a unique energy-saving system that reduces energy consumption by over 20%. The equipment includes multiple leak detection methods and uniform spray systems for increased reliability and efficiency. It integrates seamlessly into production lines, supporting continuous operation and manual processing as needed, making it ideal for processing departments in pharmaceutical, medical, and healthcare industries.

Materials used in construction include options for high corrosion resistance, ensuring longevity and compatibility with various chemical solutions. These sterilizers meet stringent GMP and FDA compliance requirements, making them suitable for critical medical applications. For easy maintenance, they offer CIP systems to facilitate quick, contamination-free cleaning. With customizable features and engineering support, SHINVA offers tailored solutions to meet specific operational needs.

Benefits

- Ensures product integrity through precise temperature control, reducing the risk of degradation.

- Lowers energy costs by over 20% with an innovative energy-saving system.

- Minimizes labor requirements with automated cycles and leak detection.

- Complies with GMP and FDA standards for regulatory assurance.

- Integrates flexibly into existing production lines to improve operational efficiency.

- Applications

- Pharmaceutical liquids, Small volume injections, Liquid medicines, Oral liquids, Biopharmaceuticals, Ampoules, Venous infusion bottles, Chemical solutions, Prefilled syringes, Powder-liquid multi chamber bags, Glass bottles

- End products

- Iv drip solution bottles, Eye drops vials, Insulin prefilled syringes, Buffered saline solution, Lidocaine ampoules, Injectable biologics, Cough syrup, Liquid antibiotics, Vitamin b12 shots, Dual-chamber bags for tpn (total parenteral nutrition)

- Steps before

- Washing, Leak detection

- Steps after

- Cooling, Drying, Packing

- Input ingredients

- ampoules, oral liquid bottles, small volume glass bottles, venous infusion bottle package, suspension drugs, emulsion drugs, heat sensitive chemical products, prefilled syringe, powder-liquid multi chamber bag

- Output ingredients

- sterilized products, leak detected ampoules, uniformly heated products, dried products, checked leakage products

- Market info

- Shinva is known for manufacturing medical equipment, including sterilization and disinfection devices, radiotherapy products, and diagnostic imaging systems, demonstrating expertise in healthcare solutions and a strong reputation for quality in the medical industry.

- Heating Method

- Moist Heat/Super-heated Water

- Temperature Control

- High accuracy (exclusive patent)

- Cooling Method

- High cooling efficiency

- Automation

- Dynamic sterilization

- Energy Efficiency

- 20% energy saving system

- Leak Detection Method

- Multiple

- Compatibility

- Ampoule, oral liquid, glass bottles

- Cycle Temperature

- Below 100℃

- Working Mechanism

- Spray system, water bath, rotary sterilization

- Integrated Steps

- Sterilization, leak detection, washing

- Temperature Control Strategy

- Exclusive patent

- Energy Efficiency

- Unique energy-saving system, 20% savings

- Automation Level

- Dynamic sterilization

- Batch vs. Continuous Operation

- Batch

- Cleaning Method

- New washing method, high efficiency

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Customized based on facility

- Tank size

- Varies by model

- Control panel type

- Digital interface

- Discharge method

- Automated discharge

- Control System Type

- PLC-controlled

- Energy Saving System

- Yes, saving more than 20%

- Integration Possibilities

- Suitable for various product types

- Dynamic Sterilization

- For moving liquid medicine

- Spray System Design

- Optimized and Uniform Spray

- Air Circulation System Design

- High efficiency cooling and drying