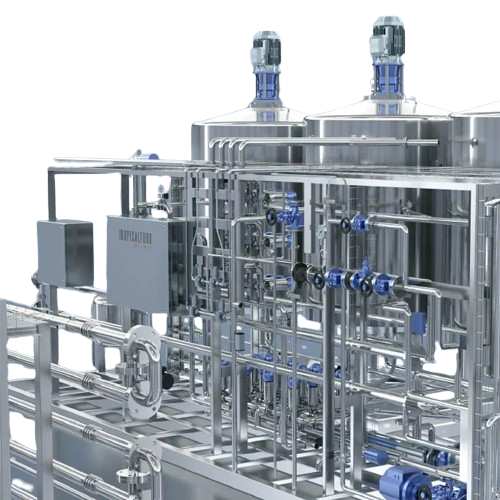

Coconut processing line for green coconut water and cream

Enhance your coconut processing with a fully automatic line that maximizes extraction yield and preserves nutritional qualities, ensuring high-quality coconut water and cream production.

Processes and Packages Multi-Fruit Products Efficiently

The Mini Industry Line 200 from Tropical Food Machinery is a compact and versatile solution designed for food processing companies and beverage manufacturers dealing with diverse fruit and vegetable applications. This line stands out with its seamless integration of processes including washing, shredding, and aseptic filling, making it ideal for small-scale operations that require high-quality output without the need for extensive space. Capable of processing various fruits for products such as mango jam, papaya purée, and coconut water, it supports throughputs ranging from 3,000 to 10,000 kg/h. The system operates continuously with full automation, facilitated by advanced PLC controls to ensure precise processing and packaging. Energy efficiency is further enhanced by optimized motor controls, reducing operational costs. Constructed with durable stainless steel options, it offers excellent corrosion resistance, making it suitable for tropical fruit processing conditions. The line complies with industry standards for hygiene and safety, ensuring your products meet market requirements. Maintenance is simplified by an integrated CIP system, which guarantees quick and effective cleaning, minimizing downtime. Tropical Food Machinery provides customization and engineering support to tailor the Mini Industry Line 200 to specific production needs.

Benefits

- Maximizes productivity by integrating multi-stage processing within a compact unit.

- Reduces operational costs with energy-efficient motor technology.

- Ensures consistent product quality through seamless cleaning and maintenance capabilities.

- Simplifies scaling up production for diverse fruit and vegetable applications.

- Compliance with hygiene and safety standards ensures market-ready products.

- Applications

- Fruit beverage production, Tomato sauce production, Fruit in pieces or chunks, Fruit processing, Jam production, Coconut milk processing, Fruit purée production, Coconut water processing, Coconut cream processing, Concentrated juice production, Fruit juice production

- End products

- Mixed fruit drink, Canned coconut cream, Pineapple chunks, Banana chips, Mango jam, Papaya purée, Orange juice, Coconut water bottles, Packaged coconut milk, Tomato ketchup, Apple juice concentrate

- Steps before

- Fruit pre-treatment, Washing Machine, Sorting Belt, Shell Removal, Blanching, Juice Extraction, Shredder, Preheater, Press Refiner

- Steps after

- Decanter (optional), Sterilization, Storage, Mixing, Homogenizer, Aseptic Filling

- Input ingredients

- banana, coconut, green coconut water, mature coconut cream, fresh fruit

- Output ingredients

- fruit purée, fruit in pieces, fruit chunks, fruit juice, concentrated juice, fruit beverage, tomato sauce

- Market info

- Tropical Food Machinery is known for manufacturing engineered-to-order (ETO) industrial equipment, specializing in fruit and vegetable processing machinery. They are reputed for innovation, quality, and global service in the food processing industry.

- Capacity

- 3, 000–10, 000 kg/h

- Automation

- Fully automatic

- Aseptic Filling

- 220 l drums / 1000 l bins

- Product Pre-treatment

- Washing / Sorting / Shell Removal

- Heating Treatment

- Pasteurization / Blanching

- Product Extraction

- Juice Extraction / Shredder

- Storage,Mixing

- Automated Control

- Sterilization

- Included in the process

- Automation level

- Fully automatic

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP

- Energy efficiency

- Optimized heat treatment

- Production capacity

- 3.000 Kg/h up to 10.000 Kg/h

- Integrated steps

- Washing, shell removal, juice extraction, pasteurization, storage, mixing, aseptic filling

- Machine footprint

- Varies by capacity

- Tank shape

- Cylindrical

- Tank size

- 220 L drums to 1000 L bins

- Discharge method

- Aseptic filling system

- Feed method

- Automated conveyor

- Integration possibilities

- Modular design for process integration

- Aseptic filling options

- 220 l drums, 1000 l bins or goodpaks