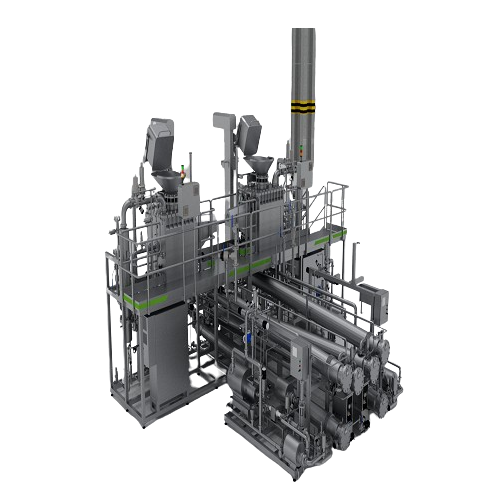

Aseptic cooking line for plant-based products

Enhance your production efficiency and product quality with an advanced double aseptic cooking line, ideal for optimizing heat transfer and preserving nutritional integrity in high-viscosity and particle-laden formulations.

Processes and Cooks in Aseptic Conditions

The Double Aseptic Cooking Line T-Sensation by Aurum Process Technology is a versatile reactor system that excels in aseptic food and industrial processing. This horizontal, stainless steel reactor processes volumes from 50 to over 1,000 liters, making it ideal for both batch and continuous operations. Its highly efficient design features multiple service fluid plates to maximize heat transfer, minimizing processing time without compromising product quality. The integrated scraping system ensures thorough mixing, enhancing heat transfer efficiency, and reducing fouling. Designed to operate under both pressurized and vacuum conditions, this reactor is suitable for a wide range of products, including those with varying viscosities and particle sizes. The T-Sensation is patent-protected, highlighting its unique capability in handling processes like evaporation, crystallization, and defrosting with high energy efficiency. Engineered for integration into complex production lines, it supports aseptic processing, ensuring the integrity and safety of end-products such as vegetable broths, apple puree, facial creams, and convenience foods. The system’s compatibility with both liquid and solid inputs further underscores its adaptability across food, body care, and infant food industries.

Benefits

- Ensures high product quality and integrity with minimal shearing and crushing.

- Enhances energy efficiency by optimizing heat transfer, reducing operational costs.

- Minimizes product loss and cleaning cycle downtimes, enhancing production efficiency.

- Adapts to a wide range of viscosities and product types, offering flexibility in production.

- Supports both batch and continuous processes, increasing operational versatility.

- Applications

- Sauces, Industrial vegetable processing, Broths, Convenience food, Vegetable creams, Body care, Industrial fruit processing, Infant food

- End products

- Ready-to-eat curry, Vegetable broths, Pumpkin soup, Apple puree, Baby carrot puree, Diced carrots, Facial cream, Tomato sauce

- Steps before

- Drying, Grinding, Purification

- Steps after

- Sterilization, Packing, Cooling

- Input ingredients

- broths, industrial fruit, body care products, convenience food, sauces, vegetable creams, infant food, industrial vegetables, products of varying viscosity, products with particles of variable sizes

- Output ingredients

- processed broths, processed industrial fruit, processed body care products, processed convenience food, processed sauces, processed vegetable creams, processed infant food, processed industrial vegetables, high-quality processed product, products maintaining nutritional properties, low shearing products, products without pressure loss, products without loss during cleaning

- Market info

- Aurum specializes in the design and manufacture of custom-engineered industrial equipment, known for their innovative solutions, high-quality craftsmanship, and reliable performance in complex projects, establishing a strong reputation in the ETO equipment market.

- Processing Capacity

- 50-1000+ L

- Material

- Stainless Steel

- Heat Transfer Efficiency

- High

- Operating Pressure

- Pressurised / Vacuum

- Scraping System

- Yes

- Batch vs. Continuous

- Batch / Continuous

- Process Type

- Aseptic

- Loading Method

- Worm screw / Chain or belt-type bucket elevators

- Surface

- Scraped Plates and Heating Jacket

- Working mechanism

- Scraped surface reactor

- Batch vs. continuous operation

- Batch / Continuous

- Heat transfer efficiency

- Optimized with scraping system

- Vacuum operation

- Yes

- Automation level

- High (patented technology)

- Aseptic processing

- Yes, with direct cooling

- Integrated steps

- Evaporation, crystallizing, defrosting

- Product volume capacity

- 50–1000+ liters

- Viscosity

- Any degree

- Particle size

- Variable

- Product integrity maintenance

- Yes

- Reactor Size

- 50–1000+ L

- Material

- Stainless Steel

- Heat Transfer Surface

- Maximized through plate design

- Product Loading Type

- Worm screw or belt-type bucket elevators

- Orientation

- Horizontal

- Internal Plates

- For service fluid flow

- Scraping System

- Optimized for mixing and heat transfer

- Reactor volume

- 50–1000+ liters

- Material

- Stainless steel

- Heat transfer design

- Scraped surface

- Operational Mode

- Batch / Continuous

- Integration possibilities

- Aseptic processing systems

- Load method

- Worm screw / Chain or belt-type bucket elevators