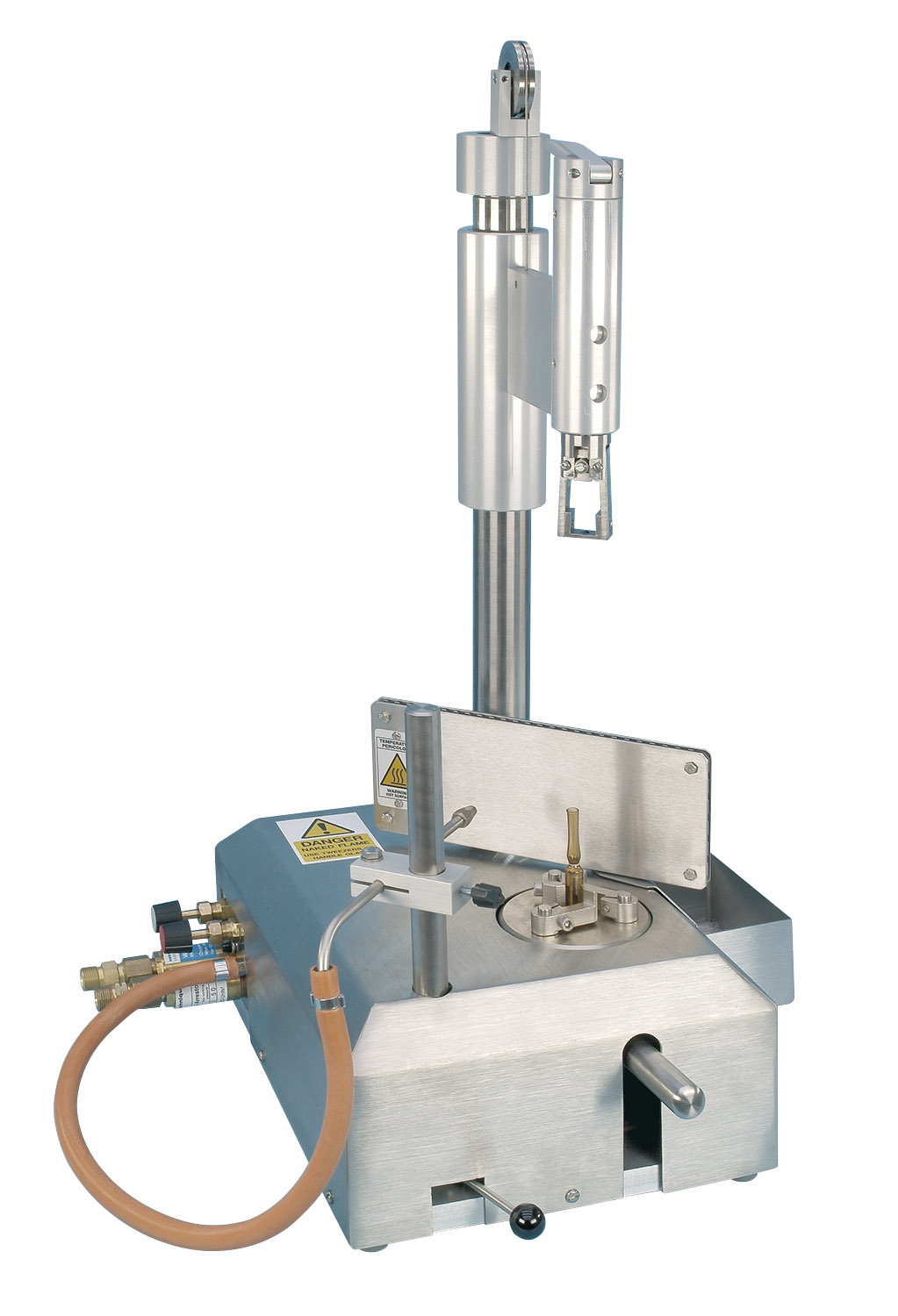

Benchtop ampoule opening and closing equipment

The procedure for opening or closing ampoules requires you to handle gas and an open flame. Therefore, safety is a major concern during operation, as it can cause an explosion without an appropriate device such as a flame arrester to prevent such fire hazards.

Automated opening and sealing of ampoules for R&D and small-scale production

The OC Ampoule Opener and Closer, from Adelphi, is an automated ampoule opening and sealing system. The system uses an open flame from oxygen and natural gas/ propane at 0.5 bar to melt glass and open or seal ampoules. As the flame approaches the glass, an electric switch activates the rotating chuck when the flame melts the glass to open the ampoule. In closing ampoules, gripper jaws are placed onto the ampoule neck. The flame is then applied until the glass becomes elastic and a counterweight pulls the gripper jaws to draw off the ampoule neck and create a rounded finish.

The unit can open and seal 1mL to 50mL ampoules with a maximum output of 600 pieces per hour. It is equipped with flash back arrestors in the gas inlets to avoid fire hazards and ensure operator safety. This equipment is designed to handle closed-type ampoules and open-type ampoules after washing. It has compact dimensions (380mm x 400mm x 660mm) that can easily fit in a small workbench and be ordered in 110V 60Hz version.

Benefits

- Wide range of ampoule sizes are applicable (1mL-50mL)

- Output up to 600 ampoules per hour

- Safe to operate due to flash back arrestor in gas inlets

- Compact size, can fit in a small workbench (380mm x 400mm x 660mm)