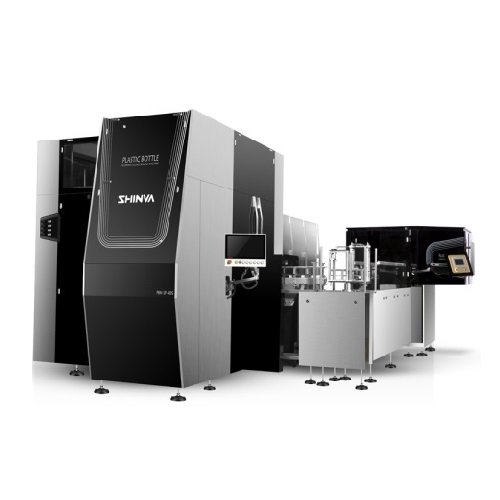

Blow-fill-seal system for small volume injection production

Ensure precise aseptic liquid packaging with integrated blow-fill-seal technology, streamlining your production line by combining blow molding, filling, and sealing into one seamless operation for enhanced safety and efficiency.

Blows, Fills, and Seals Plastic Bottles

The Plastic Bottle BFS Machine from Shinva integrates blow molding, filling, and sealing into one seamless process for producing sterile liquid products. With its high automation and SmartPack features, it ensures efficient production of small volume injections like vaccine ampoules and sterile saline solutions. This equipment is ideal for pharmaceutical and medical device industries, offering reliable aseptic packaging with processing capabilities tailored to your needs. The BFS machine supports continuous operation under stringent GMP and FDA conditions, providing advanced leak detection and remote monitoring compatibility. Its robust construction in stainless steel options ensures long-lasting performance and minimal maintenance, making it a valuable addition to any facility focused on sterile production.

Benefits

- Enhances production efficiency by combining blow molding, filling, and sealing in one step.

- Ensures product safety with integrated aseptic packaging solutions.

- Minimizes labor costs through high automation and remote monitoring capabilities.

- Complies with GMP and FDA standards for pharmaceutical and medical products.

- Provides long-term durability with corrosion-resistant stainless steel construction.

- Applications

- Plastic bottles, Medical devices, Small volume injections, Aseptic liquid packaging, Pharmaceutical equipment, Sterilization products

- End products

- Antiseptic wipes, Ophthalmic solution dispensers, Sterile nutrient solutions, Single-dose vials, Pre-filled syringes, Medical device components, Intravenous fluid bottles, Sterile saline solutions, Vaccine ampoules, Diagnostic reagents

- Steps before

- Plastic bottle forming, Liquiofilling, Bottle sealing, Aseptic packing

- Steps after

- Sterilization, Packaging, Leak detection, Light inspection

- Input ingredients

- plastic bottle preforms, aseptic liquid, packaging materials

- Output ingredients

- sealed plastic bottles, small volume injection products, sterilized ampoules

- Market info

- Shinva is known for manufacturing medical equipment, including sterilization and disinfection devices, radiotherapy products, and diagnostic imaging systems, demonstrating expertise in healthcare solutions and a strong reputation for quality in the medical industry.

- Automation

- High automation level

- Performance

- Stable performance

- Safety

- High safety

- Packing Technology

- Blow-Fill-Seal (BFS)

- Production Application

- Terminal or non-terminal sterilization plastic bottles

- System Integration

- Automation and Informatization System

- Inspection Type

- Automatic Light Inspector for Plastic Ampoule

- Automation level

- High automation

- Working mechanism

- Blow-Fill-Seal (BFS) technology

- Integrated steps

- Forming, Filling, Sealing

- Batch vs. continuous operation

- Continuous inline process

- Safety features

- High safety standards

- Abrasion resistance

- High abrasion resistance

- Biological compatibility

- Suitable for medical applications

- Corrosive resistance (e.g. acids)

- Corrosion-resistant materials

- Cleanability

- Easy to clean

- Density/particle size

- 0.5–2.5 g/cm³

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- SCADA / DCS

- Customization Options

- Leak detection integration

- Automation level

- High automation

- Connectivity

- IoT Ready / Industry 4.0

- Footprint size

- Compact design