Aseptic filling solutions for Rtu vials, cartridges, and syringes

Optimize your aseptic filling processes with a system that minimizes product loss and adapts quickly to various container formats, ensuring seamless integration into high-speed production lines for personalized and biopharmaceutical products.

Fills and Closes RTU Vials, Cartridges, and Syringes

The flexpro 50 from groninger is an advanced aseptic filling machine tailored for the pharmaceutical and biotech sectors, excelling in filling and closing ready-to-use (RTU) vials, cartridges, and syringes. This system features the smartfill technology, incorporating 100% In-Process-Control (IPC) to minimize product loss and ensure precision during start-up and production. Ideal for applications in biopharmaceuticals, personalized medicines, and injectable therapies, it accommodates end-products like monoclonal antibodies, mRNA vaccines, and oncology drugs. Supporting high-speed, continuous operations, it seamlessly integrates into automated production lines and offers flexible format changeovers without tools, thanks to the quickconnect feature. Constructed for compliance with GMP standards, it assures sterile conditions via safetransfer methods, safeguarding the sterile introduction of components into the aseptic area. With scalable output and engineered customization, the flexpro 50 suits diverse production scales, from R&D labs to full-scale manufacturing.

Benefits

- Minimizes product loss with 100% In-Process-Control, enhancing yield and cost-efficiency.

- Reduces set-up time by up to 60% with tool-free quickconnect changeovers.

- Ensures sterile integrity of RTU components through safe transfer, enhancing operational safety.

- Offers scalability from lab-scale to full-scale production, accommodating growth and varied production needs.

- Complies with GMP standards, ensuring regulatory compliance and product quality.

- Applications

- Personalized medicines, Syringes, Injectable medicines, Pharmaceutical fillings, Aseptic fillings, Cell and gene therapies, Biopharmaceuticals, Ready-to-use (rtu) containers, Cartridges, Eye drops, Nasal sprays, Rtu vials

- End products

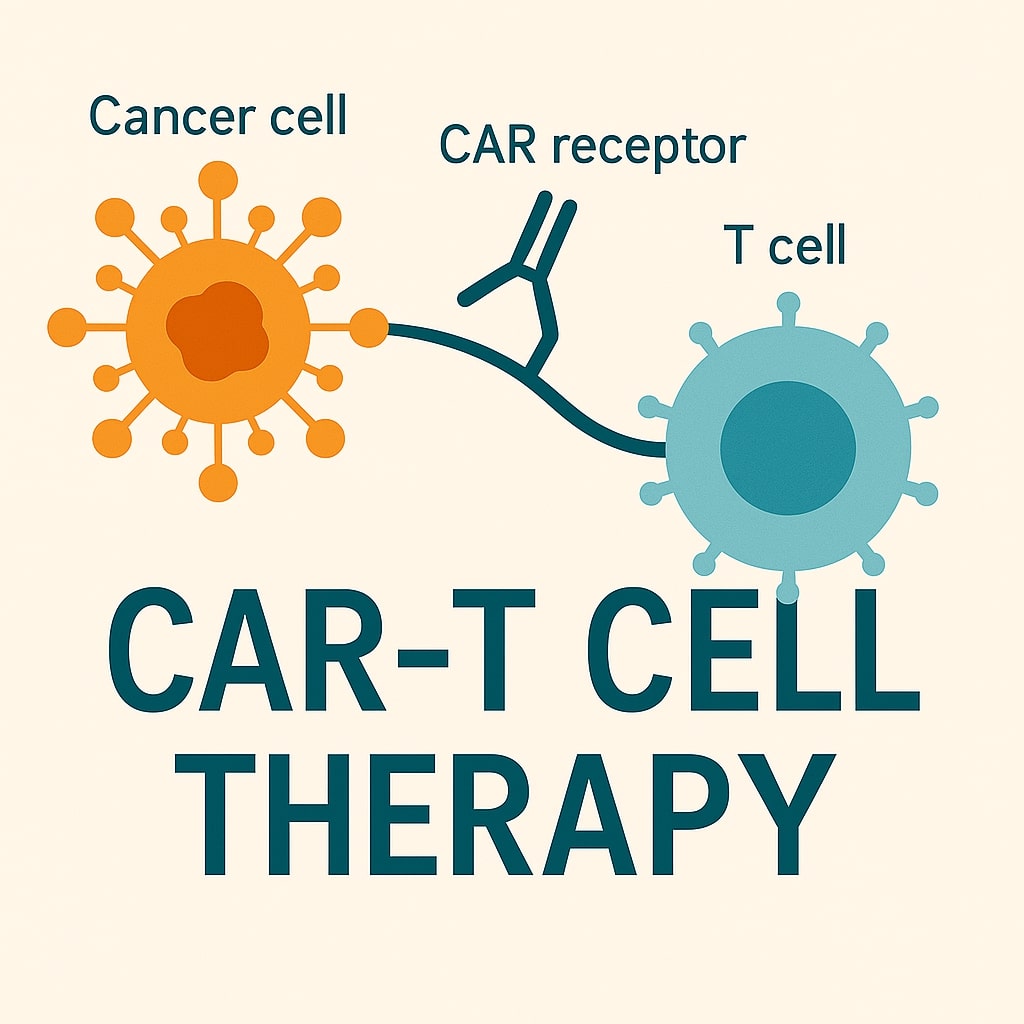

- Preservative-free eye drops, Personalized gene therapy doses, Car-t cell therapies, Intravenous rtu bags, Subcutaneous injection cartridges, Insulin, Monoclonal antibodies, Single-dose prefilled syringes, Lyophilized powder injections, Oncology drugs, Mrna vaccines, Sterile injectable vials, Eye ointment dispensers, Anti-inflammatory injectables, Nasal decongestant sprays

- Steps before

- Component preparation, Sterilization of RTU containers, Pre-sterilized component introduction

- Steps after

- Product inspection, Labeling, Packaging, Quality control

- Input ingredients

- RTU glass vials, RTU polymer vials, pre-sterilized components, nested ready-to-use syringes, vials, cartridges, double bags

- Output ingredients

- filled syringes, filled vials, filled cartridges, aseptic transferred components

- Market info

- Groninger is known for its expertise in manufacturing high-quality filling and packaging machinery for the pharmaceutical, cosmetics, and consumer healthcare industries, with a strong reputation for innovation, precision engineering, and customer-focused solutions.

- Automation

- Fully automated

- Process Control

- 100% In-Process-Control (IPC)

- Flexibility

- Fast changeover between different formats

- Filling Method

- Smartfill technology

- Loss Minimization

- Eliminates product loss during start-up, production, and end of batch

- Transfer Type

- No-touch transfer (NTT)

- Handling Changeover

- Tool-less quickconnect system

- Sorting Method

- smarttrack technology

- Airflow

- Innostream optimized airflow

- Scalability

- Scalable from R, D through clinical studies to various production performance classes

- Availability

- High degree of automation, maximized OEE

- Operating Flexibility

- Fastlane approach to reduce delivery times of format parts

- Machine Operability

- 30% more effective operability, usually designed for one-sided operation

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- High-speed system / Fully automated

- Changeover time

- Minimal due to quickconnect

- Cleaning method

- CIP / SIP

- Energy efficiency

- Optimized with smartfill technology

- Safe transfer method

- Safetransfer / No-touch transfer

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Touch screen / HMI

- Integration possibilities

- SCADA / ERP

- Changeover flexibility

- Quickchange

- Tool-free component change

- Quickconnect

- Automation level

- Fully automated