Cartridge and disposable syringe closing solution

Ensure precise closing of pre-filled syringes and cartridges with customizable stopper insertion settings, designed to maintain pharmaceutical standards and enhance product integrity.

Inserts and Secures Stoppers in Syringes and Cartridges

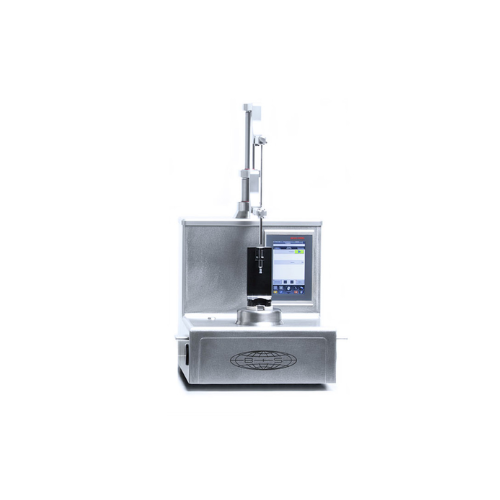

The SVP 4600 from Bausch+Ströbel is a semi-automatic closing machine specifically designed for processing disposable syringes and cartridges in pharmaceutical and biotech industries. Its compact design allows integration into existing production lines with ease, offering flexibility with adjustable stopper insertion depth and speed. The SVP 4600 is suitable for H2O2 decontamination, enhancing its application in sterile environments. It supports gas flushing and vacuum insertion for enhanced sealing quality, making it ideal for producing pre-filled syringes, insulin cartridges, and other critical medical applications. The machine’s touch screen interface simplifies operation and monitoring, and its servomotor drive ensures precise control. Designed to meet pharmaceutical standards, it can handle container diameters up to 35 mm and heights between 32 and 160 mm, accommodating a wide range of product types. Optional features include gas flushing and the assembly of add-on safety features, providing further customization options.

Benefits

- Ensures precise and consistent stopper placement, enhancing product quality and reliability.

- Adapts to various syringe and cartridge sizes, providing flexibility in production.

- Enhances sterile processing capability with H2O2 compatibility and vacuum insertion.

- Streamlines operations with an intuitive touch screen for easy monitoring and control.

- Minimizes integration challenges with a compact, easily scalable design.

- Applications

- Disposable syringes, Cartridges, Pharmaceuticals

- End products

- Heparin syringes, Vaccine syringes, Biologic drug cartridges, Epinephrine auto-injectors, Disposable medical syringes, Pre-filled syringes, Glass syringes with plunger stopper, Insulin cartridges

- Steps before

- Dosing, Container preparation

- Steps after

- Sterilization, Packing

- Input ingredients

- cartridges, disposable syringes, plunger stopper

- Output ingredients

- closed cartridges, closed disposable syringes

- Market info

- Bausch Stroebel specializes in manufacturing high-quality pharmaceutical packaging and processing machinery, renowned for their precision, reliability, and innovation in filling and packaging lines for the pharmaceutical industry. They are respected for tailored solutions and advanced engineering.

- Container diameter

- max. 35 mm

- Container height

- 32 - 160 mm

- Stopper insertion depth

- Freely selected

- Stopper insertion speed

- Freely selected

- Automation

- Semi-automatic

- Decontamination method

- H2O2 suitable

- Drive type

- Servomotor

- Operation Interface

- Touch screen panel

- Operation interface

- Touch screen panel

- Automation level

- Semi-automatic

- Decontamination suitability

- H2O2 compatible

- Stopper insertion control

- Adjustable depth and speed

- Drive type

- Servomotor

- Gas flushing capability

- Optional

- Vacuum stopper insertion

- Optional

- Safety device processing

- Optional modification

- Changeover configuration

- Optional add-on

- Qualification standards

- IQ/OQ compatible

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Cartridge and syringe closing

- Compatible

- Control panel type

- Touch screen panel

- Control panel type

- Touch screen panel

- Stopper insertion depth

- Freely selectable

- Stopper insertion speed

- Freely selectable

- Servomotor drive

- Yes

- Gas flushing option

- Yes (optional)

- Stopper insertion under vacuum

- Yes (optional)

- Assembly of add-on finger flange

- Yes, modification option