Aseptic small batch filling and closing system

Optimize your small-batch aseptic processing with this versatile system, designed for precise filling and closing of sterile liquid pharmaceuticals while maintaining stringent cleanliness standards.

Fills and Closes Sterile Liquid Pharmaceuticals

The GENiSYS® R from AST is a versatile aseptic small batch filling and closing machine designed for pharmaceutical and biologics manufacturers requiring high precision in sterile drug production. This machine integrates advanced robotic systems to efficiently fill, close, and seal vials, syringes, and cartridges, ensuring compliance with cGMP regulations. Capable of processing various container formats, it supports clinical trials and small-batch commercial production of monoclonal antibodies, vaccines, and personalized medicines. The system offers a modular configuration, allowing for seamless integration with lyophilizers and other packaging systems. Automated in-process controls and environmental monitoring enhance product yield and sterility assurance. Constructed with pharmaceutical-grade materials, the GENiSYS® R provides reliable, contamination-free operation with options for isolator or RABS aseptic barriers.

Benefits

- Enhances productivity with swift changeovers and minimized downtime, achieving a complete system reconfiguration in as little as thirty minutes.

- Ensures precise fill accuracy, reducing waste and maximizing product yield through in-process fill weight control.

- Maintains rigorous aseptic conditions with isolator or RABS options, ensuring unparalleled sterility for sensitive biologic products.

- Facilitates compliance with 21 CFR Part 11 through comprehensive electronic batch record reporting.

- Offers flexible application for diverse drug products and container formats, allowing easy adaptation to specific processing needs.

- Applications

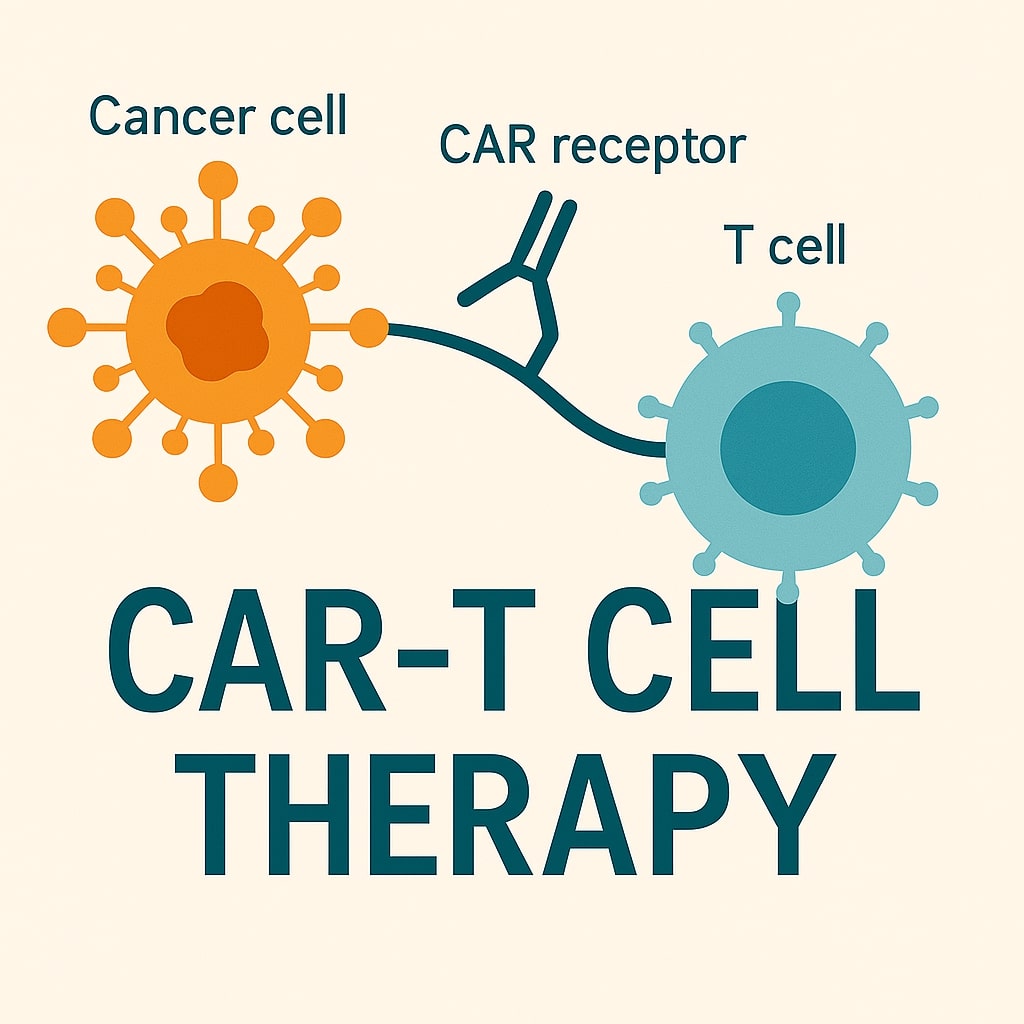

- Biologics, Personalized medicine, Vaccines, Sterile drug products, Orphan drugs, Bio-similars, Cell and gene therapy, Pharmaceuticals

- End products

- Car-t cell therapies, Insulin biosimilars, Personalized cancer vaccines, Rare disease treatments, Monoclonal antibodies, Covid-19 vaccines, Sterile injectables

- Steps before

- Container preparation, Pre-sterilization, Tub or bag opening, System setup and configuration, Pump calibration

- Steps after

- In-process fill weight inspection, Vial sealing, Lyophilization, Final product inspection, Batch record generation

- Input ingredients

- pre-sterilized vials, pre-sterilized syringes, pre-sterilized cartridges, ready-to-use nested vials, ready-to-use nested syringes, ready-to-use nested cartridges

- Output ingredients

- sealed vials, sealed syringes, sealed cartridges, aseptically processed drug products, sterile drug products

- Market info

- AST is known for its expertise in designing and manufacturing customized engineered-to-order equipment for industrial applications, renowned for precision engineering, innovation, and reliable solutions tailored to meet unique customer specifications and industry standards.

- Machine Model

- GENiSYS®R20

- Size (Dimensions)

- 4225mm x 1400mm x 2405mm

- Production Rate

- Up to 20 upm

- Filling Accuracy

- Up to ±0.5%

- Vial Sizes

- 2mL to 50mL

- Syringe Sizes

- 0.5mL to 50mL

- Cartridge Sizes

- 1mL to 20mL

- Dispense Options

- Peristaltic, Rotary Piston

- Vial Closing Methods

- Serum or Lyo stoppers

- Vial Sealing Methods

- Crimp or Press-fit capping options

- Syringe / Cartridge Closing Method

- Vacuum, Vent-Tube and Vent/Vac Combo

- Barrier System

- RABS or Isolator

- Automation level

- Full automation with robotic integration

- Batch vs. continuous operation

- Small batch processing

- Changeover time

- 30 minutes

- Cleaning method

- Sterilization with hydrogen peroxide (VHP)

- Process monitoring

- Real-time fill weight and environmental monitoring

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- GMP Compliance

- cGMP

- Control panel type

- ASTView on a 21" color touchscreen

- Control panel type

- ASTView on a 21" color touchscreen

- Modular system design

- Customizable modules (MBO, SABO, MTO, ATO, FCM, VSM)

- Integration with barrier systems

- Restricted Access Barrier System (RABS) or Isolator

- In-process control options

- Real-time fill weight feedback and control

- Dispense options

- Multiple dispense and closing options

- Product compatibility

- Ready-to-use, nested vials, syringes, and cartridges

- Batch report system

- Electronic Batch Record (EBR) System