Cip cleaning systems for dairy processing plants

Optimize cheese production with precise curd handling and exceptional stirring performance, ensuring consistent quality across a wide range of cheese types.

Processes a Variety of Cheese Types

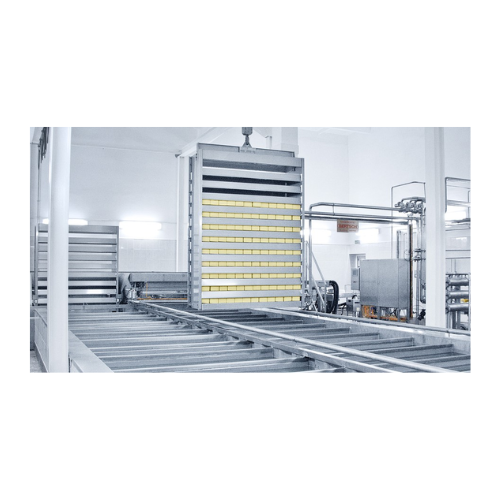

The Universal Cheese Vat from BERTSCHfoodtec is designed to streamline the production of a diverse range of cheese varieties, from soft to hard types, including mozzarella and artisanal selections. Utilizing an efficient agitation and cutting system, it ensures a uniform curd size and optimal cheese development. Ideal for dairy producers and small-scale farm dairies, this vat integrates seamlessly into existing dairy plants, supporting applications such as filling, pressing, and brining. It offers remote monitoring capabilities, enabling efficient process control and optimization. Constructed from high-grade stainless steel, it ensures durability and corrosion resistance, fitting into automated production lines with ease. The vat also includes CIP cleaning systems to maintain the highest hygiene standards and reduce downtime. Customization options allow the adaptation of stirring and cutting configurations to meet specific production requirements.

Benefits

- Enhances production efficiency with versatile cheese type capabilities.

- Maintains high product quality through precise agitation and cutting.

- Lowers maintenance needs with robust stainless steel construction.

- Reduces downtime with integrated CIP cleaning systems.

- Provides operational flexibility with remote monitoring and control.

- Applications

- Cream, Milkshakes, Milk products, Mozzarella, Whey products, Cheese, Semi-hard cheese, Soft cheese, Cream cheese, Curd cheese, Pizza cheese, Yoghurt, Butter, Quark, Hard cheese, Dairy products, Soured milk products, Farm dairies

- End products

- Feta cheese, Emmental cheese, Skyr, Whipped cream, Gruyère cheese, Cultured butter, Greek yoghurt, Gouda cheese, Blue cheese, Artisan gouda, Buttermilk, Ricotta cheese, Farmhouse cheddar, Cheddar cheese, Cottage cheese, Whey protein powder, Lactose-free milkshake

- Steps before

- Milk reception, Degassing, Quantification, Milk analysis, Standardisation, Homogenisation

- Steps after

- Cheese cutting, Packaging, Cooling, Ripening

- Input ingredients

- milk, sheep milk, goat milk

- Output ingredients

- hard cheese, semi-hard cheese, soft cheese, curd cheese, quark, cream cheese, blue cheese, mozzarella, pizza cheese, yoghurt, soured milk products, cream, butter, milkshakes, ESL products, UHT products, desserts, whey products

- Market info

- Bertsch is known for manufacturing high-quality industrial engineered-to-order (ETO) equipment, specializing in products like tanks, pressure vessels, and heat exchangers. They are reputed for their custom engineering solutions and robust construction standards.

- Material

- Stainless steel

- Heating Method

- Hot water and steam

- Emptying Method

- Double cone with two outlets

- Automation

- PLC-controlled

- Control

- Ethernet remote monitoring

- Stirring System

- Self-supporting agitators

- Cutting System

- Electro-polished cutting units

- Valves

- Flush with the floor

- Brine Handling

- Automatic control

- Cooling System

- Brine cooler

- Pressing System

- Automatic cheese block holding

- CIP/SIP

- CIP 121°C / SIP 135°C

- Automation level

- Manual / PLC / SCADA

- Cleaning method

- CIP / Manual

- Batch vs. continuous operation

- Batch / Inline Continuous

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Agglomeration risk

- None due to careful handling

- Fluid Type

- Brine solutions for cheese handling

- Product Form

- Curd cheese, quark, cream cheeses

- Milk handling capability

- Reception, treatment, and cooling

- Tank shape

- Double-O shaped

- Construction Material

- Stainless Steel

- Vat surface area

- Large surface area

- Discharge method

- Double cone with two outlets

- Machine component separation

- Gear chamber and whey suction drive hermetically separated

- Outlet valve installation

- Installed flush with the floor

- Cutting and stirring system

- Self-supporting agitators without bottom gearing

- Emptying capability

- Fast, gentle, complete emptying

- Control panel type

- Customer-specific

- Integration capabilities

- Remote monitoring with Ethernet

- Control concept

- Tailor-made to customer specifications

- Size,volume customization

- Universal cheese vat with various filling volumes