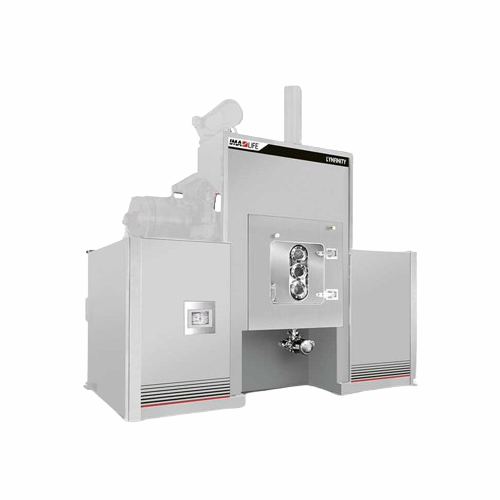

Continuous aseptic spray-freeze-drying system

Achieve higher sterility and improved product uniformity with a continuous aseptic spray-freeze-drying solution that minimizes downtime while optimizing process efficiency from formulation through to final packaging.

Processes Liquid Formulations into Lyophilized Powders

The LYNFINITY system from IMA Life is a continuous spray-freeze drying solution designed for biopharmaceutical applications. It uniquely combines cryogenic spray-freezing with advanced freeze-drying to transform liquid formulations into uniform, sterile lyophilized powders. Ideal for monoclonal antibodies, vaccines, and enzymatic drug products, LYNFINITY ensures high sterility with total containment from start to finish. The continuous process eliminates scale-up challenges and reduces downtime, significantly increasing throughput. It integrates seamlessly with existing production lines, offering enhanced automation and reduced operating costs. With a reduced equipment footprint, it decreases both CAPEX and OPEX, while its advanced design boosts product quality by minimizing cake thickness and eliminating vapor flow limitations. The system is fully GMP-compliant, making it suitable for demanding pharmaceutical and biotech environments.

Benefits

- Increases sterility assurance with total containment from formulation to powder filling.

- Enhances production efficiency by minimizing scale-up and scale-down challenges.

- Reduces operating costs with a compact footprint and lower energy consumption.

- Improves product quality and uniformity through gentle, controlled drying processes.

- Boosts flexibility and reduces downtime with continuous operation and seamless integration.

- Applications

- Biopharmaceuticals, Pharmaceutical powder, Enzymes, Liquid formulations

- End products

- Vaccines, Monoclonal antibodies, Biologics, Enzymatic drug products, Liquid vaccine formulations, Lyophilized pharmaceutical powders

- Steps before

- Fermentation, Formulation

- Steps after

- Powder Filling, Packaging

- Input ingredients

- liquid product, bulk liquid product, fermentation product

- Output ingredients

- dried particles, freeze-dried product, spherical dried powder, lyophilized spheres, vials with lyo spheres

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Process Type

- Continuous Aseptic Spray-Freeze-Drying

- Production Process

- From fermentation to final packaging

- Sterility Assurance Level (SAL)

- High

- Product Transport

- Gentle drying process

- Operation Type

- Continuous

- Powder Discharge

- Discharge of dried particles

- Drying Module Temperature Control

- Controlled spray into cryogenically cooled chamber

- Drying Time

- Reduced

- Freezing Method

- Spray into cryogenically cooled freezing chamber

- Containment

- Total from formulation to powder filling

- Flexibility

- Greater throughput flexibility with minimized scale-up and scale-down challenges

- Reconstitution Time

- Faster, due to increased Specific Surface Area (SSA)

- Continuous process

- Yes

- Automation level

- Fully automated

- Batch vs. continuous operation

- Continuous

- Integrated steps

- Sterile formulation to powder filling

- Cleaning method

- CIP

- Changeover time

- Minimal

- Biological compatibility

- Yes

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 50–1000 µm

- Viscosity

- Low to Medium

- Container size

- Variety (vials, syringes, inhalation systems)

- Compact footprint

- Reduced plant footprint

- Discharge method

- Total containment from formulation to powder filling

- Control panel type

- PLC-controlled

- Machine footprint

- Space-saving design

- Spray freezing process

- Controlled spray into cryogenically cooled chamber

- Transport method

- Gentle transport to prevent agglomeration

- Container compatibility

- Vials, syringes, inhalation systems

- Spray freezing chamber

- Cryogenically cooled

- Control panel type

- Touchscreen HMI

- Integration possibilities

- SCADA Integration

- Compact footprint

- Yes

- Discharge method

- Automatic continuous discharge