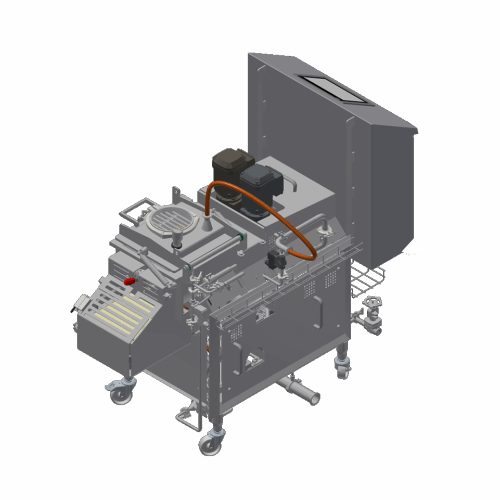

Multifunctional batch processing system for processed cheese

Enhance your production line with a sophisticated batch processing system that optimizes blending, cooking, and heating, while integrated solutions like vacuum de-aeration ensure superior product quality in diverse food applications.

Blends, Cooks, and De-aerates Food Products

The FreeTherm 10 from the Natec Network is a robust batch steam injector mixer designed for versatility and efficiency in food production. Specially engineered to handle a variety of viscosities and compositions, this equipment excels in producing processed cheese, sauces, and even specialty foods like gluten-free bread and vegan products. What distinguishes the FreeTherm 10 is its dual auger system for gentle mixing and direct steam injection for even heating, avoiding hotspots. It can seamlessly integrate into your processing line with its automated temperature control and vacuum de-aeration for enhanced density control and color stability. Designed with hygiene in mind, it features a Clean-In-Place (CIP) system, ensuring quick and contamination-free cleaning. With options for customization in mixing auger executions and processing vessel jacketing, this system meets diverse production needs. Its central control and surveillance system facilitate smooth operation and high adaptability, making it suitable for food manufacturers across sectors like dairy, meat, and plant-based products.

Benefits

- Enhances production efficiency by integrating blending, cooking, and de-aeration in a single step.

- Ensures product consistency through precise temperature control with self-cleaning probes.

- Minimizes contamination risk with a fully enclosed, sanitary CIP design.

- Adapts to diverse product requirements with customizable mixing augers and vessel options.

- Facilitates easy operation and monitoring via central control and surveillance systems.

- Applications

- Meat products, Soups, Sauces, Mozzarella, Pasta filata, Specialty food, Pet food, Fruits, Plant-based, Processed cheese, Cream cheese, Dressings, Vegetables, Vegan, Baby food

- End products

- Gluten-free bread, Alfredo sauce, Apple puree, Dog kibble, Infant formula, Tomato puree, Mashed potatoes, Almond milk, Ricotta, Vinegarette, Cheddar cheese spread, Sausages, Tofu, String cheese

- Steps before

- Blending, Feeding, Grinding, Transferring

- Steps after

- Forming, Portioning, Packing

- Input ingredients

- processed cheese ingredients, pasta filata ingredients, sauces ingredients, purees ingredients, baby food ingredients, meat ingredients, pet food ingredients

- Output ingredients

- processed cheese, pasta filata, sauces, purees, baby food, meat products, pet food, plant based products, vegan products, fruit and vegetable products, specialty food

- Market info

- Hochland Natec is known for manufacturing innovative engineered-to-order equipment and solutions for the dairy and food processing industry, specializing in cheese production and processing technologies, with a strong reputation for quality and innovation.

- Batch processing capacity

- Varies based on model

- Product temperature monitoring

- Self-cleaning temperature probes

- Mixing mechanism

- Independently controlled augers

- Heating method

- Direct steam injectors

- De-aeration system

- Integrated vacuum system

- Automation level

- Central control surveillance system

- Cleanability

- Fully enclosed, CIP able

- Jacketing options

- Double jacketing available

- Working mechanism

- Batch processing with independent augers

- Integrated steps

- Mixing, heating, and de-aeration

- CIP principles

- Fully enclosed, automatic CIP

- Batch vs. continuous operation

- Batch

- Temperature monitoring

- Unique self-cleaning temperature probes

- Heating method

- Direct steam injection

- De-aeration system

- Integrated vacuum system

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Stainless steel

- Abrasion resistance

- Moderate

- Biological compatibility

- Food grade

- Density/particle size

- Varied product types

- Feed method

- Independently controlled augers

- Discharge method

- Enclosed catchment bin

- Control panel type

- Central control surveillance system

- Control panel type

- Central control and surveillance system

- Discharge method

- Enclosed catchment bin

- Steam conditioning unit

- Optional

- Shaft seal upgrade

- Optional

- Double jacketing of processing vessel

- Optional

- Mixing auger executions

- Different options available

- Further options

- On request