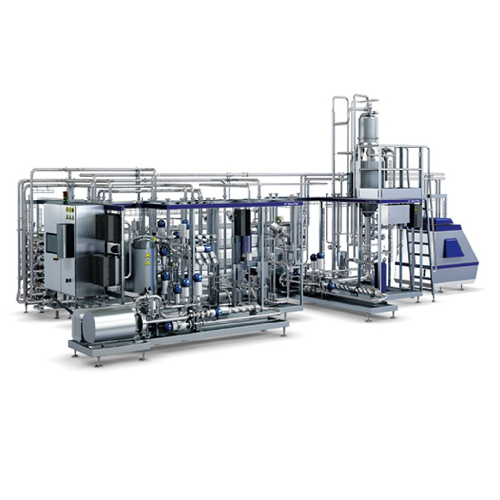

Continuous ultra-high temperature treatment for prepared food products

Optimize your prepared food production with continuous ultra-high temperature processing, ensuring consistent quality and safety for a wide range of viscous products, from soups and sauces to dairy and baby foods.

Processes Aseptic Liquid Food Products Continuously

The Tetra Pak® Indirect UHT Unit PFF leverages Tetra Pak’s extensive expertise in aseptic processing to deliver high-quality solutions for food manufacturers. This unit stands out for its ability to handle a wide range of viscosities, effectively processing soups, sauces, desserts, fruit preparations, and baby food. Utilizing an advanced tubular heat exchanger, it integrates seamlessly into production lines for continuous operation. Its capacity ranges from 2,000 to 20,000 liters per hour, depending on product requirements.

Automation is achieved through a PLC-based control system, offering both remote monitoring and precise parameter adjustments to enhance production efficiency. The machine’s design prioritizes energy efficiency by optimizing heat transfer and retention times, significantly reducing operational costs. Constructed with hygienic materials, it meets rigorous food safety standards while allowing for configurable cleaning cycles, ensuring minimal downtime. For industries requiring scalability, this unit offers expansion capabilities to meet future demands, supported by Tetra Pak’s engineering expertise.

Benefits

- Enhances product quality by maintaining particle integrity up to ø 25 mm.

- Reduces operational costs through energy-efficient heat transfer.

- Ensures robust food safety with a hygienic design and advanced cleaning protocols.

- Minimizes waste and maximizes yield with precise automated filling.

- Easily adapts to future production needs with configurable design options.

- Applications

- Soups, Sauces, High viscous products, Prepared food products, Desserts, Fruit preparations, Tomato products, Baby food, Low viscous products

- End products

- Ketchup, Infant cereal, Fruit yogurt base, Butternut squash soup, Cream of mushroom soup, Caramel sauce, Custard, Chocolate pudding, Gravy, Marinara sauce, Salsa, Spaghetti sauce, Apple compote, Fruit puree, Mashed potatoes

- Steps before

- Blending, Pre-mixing, Homogenizing

- Steps after

- Aseptic Filling, Cooling, Packaging

- Input ingredients

- soups, sauces, desserts, fruit preparations, tomato products, baby food, low or high viscous products, products with particles, products without particles

- Output ingredients

- aseptic food products, high quality food products, ambient-storable food products

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- 2, 000 – 20, 000 l/h

- Automation

- PLC-based control

- Heat treatment

- Optimized for quality and particle integrity

- Particle integrity

- Up to ø 25 mm

- Aseptic design

- Yes

- Quality control

- Consistent stability and texture

- Filling and emptying

- Automated and optimized

- Water saving feature

- Up to 2, 600 l/h

- Cooling medium

- Eco vacuum and Eco cooling

- Flexibility

- Hardware configuration and product versatility

- Working Mechanism

- Continuous UHT Treatment

- Flow Type

- Inline Continuous

- Automation Level

- PLC-based Control

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning Method

- CIP

- Changeover Time

- Optimized with Automation

- Energy Efficiency

- Optimized Heat Treatment

- Product Versatility

- Processes Viscous Products with Particles

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat Sensitivity

- Suitable for heat-sensitive products

- Foaming Potential

- Minimal foaming design

- Product Versatility

- Smooth/Particulate

- Product Types

- Soups, sauces, desserts, fruit preparations, tomato products, baby food

- Footprint

- Compact design

- Construction type

- Tubular heat exchanger

- Material

- Stainless steel

- Support frame

- Modular

- Size range

- 2, 000 – 20, 000 l/h

- Design flexibility

- Future proof

- Discharge method

- Automated

- Heat exchanger type

- Tubular

- Control panel type

- PLC-based

- Integration possibilities

- PlantMaster supervisory system

- Hardware configuration

- Flexible

- Heat exchanger design

- Flexible

- Product type compatibility

- Aseptic/non-aseptic, smooth/particulate