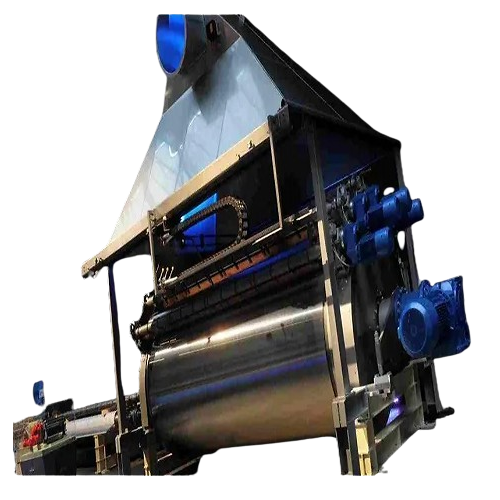

Contact drum dryer for industrial food and chemical processing

Optimize your drying process with a contact drum dryer that ensures efficient moisture removal and product integrity, crucial for maintaining the unique properties of your end products during continuous and high-speed operations.

Continuously Dries and Conditions Slurries and Liquids

The ANDRITZ Gouda contact drum dryer stands out for its precise, continuous indirect drying method, ideal for food and chemical processing. Using steam-heated drums, it swiftly evaporates moisture from liquids and slurries, enhancing product stability and preserving key qualities like taste and texture. Applications range from baby food and whey protein to industrial-grade chemical additives. Designed for seamless integration into production lines, it offers high thermal efficiency and hygienic operation, aligning with HACCP standards. The system is advanced in energy efficiency, reducing consumption through its closed-loop design, and supports high throughput. Available with protective thermal spray coating (HVAF), it ensures long-lasting durability and compliance with European and US food-grade regulations. Maintenance is streamlined through features like adjustable knife holders and a user-friendly control system, allowing easy product adjustment and consistent operation.

Benefits

- Preserves product integrity by minimizing thermal exposure time.

- Achieves uniform drying with steam-heated drum for consistent quality.

- Enhances productivity with continuous operation and high throughput.

- Meets stringent hygiene standards, reducing contamination risks.

- Extends equipment lifespan with wear-resistant HVAF thermal spray coating.

- Applications

- Chemicals, Animal proteins, Gelatin, Potatoes, Milk, Starch, Baby food, Yeast, Fruit

- End products

- Fruit leathers, Infant rice cereal, Potato flakes, Industrial milk powder, Infant oatmeal, Gelatin sheets, Chemical additives, Whey protein concentrate, Pre-gelatinized starch, Active dry yeast, Baby food puree, Dried apple slices

- Steps before

- Kitchen Preparation, Mixing, Product Treatment, Feeding into Drum

- Steps after

- Mill Sifting, Pneumatic Transport, Scraping, Product Removal

- Input ingredients

- cereal-based baby food, milk, animal proteins, yeast, pre-gelatinized starch, gelatin, potatoes, fruit, algae, chemicals, sourdough

- Output ingredients

- dried cereal-based baby food, drum-dried milk powder, dried animal proteins, dried yeast, dried pre-gelatinized starch, dried gelatin, dried potatoes, dried fruit, dried algae, dehydrated chemicals, dried sourdough

- Market info

- ANDRITZ is known for its expertise in supplying industrial ETO equipment and services, specializing in sectors like pulp and paper, hydropower, and metals. It has a strong reputation for innovation and engineering excellence.

- Drying method

- Continuous indirect

- Heat retention time

- Short

- Thermal efficiency

- High

- Temperature distribution

- Uniform

- System design

- 100% closed system

- Energy consumption

- Minimum

- Drum type

- Single and double drum

- Knife pressure control

- External adjustment

- Vacuum operation

- Available

- Protective coating

- HVAF thermal spray

- Temperature exposure

- High, short exposure

- Working mechanism

- Indirect drying

- Heat retention time

- Short

- Batch vs. continuous operation

- Continuous

- Hygienic standards

- High

- Vacuum operation

- Available

- Coating method

- Thermal spray coating (HVAF)

- Cleanability

- High hygienic standards

- Corrosive resistance (e.g. acids)

- Protective thermal spray coating (HVAF)

- Abrasion resistance

- Thermal spray coating

- Drum size

- Customizable (based on the application)

- Footprint

- Compact for space efficiency

- Discharge method

- Scraping knife

- Control panel type

- PLC / Manual

- Custom Versions

- Multiple versions for different applications

- Design

- Single or double drum

- Knife pressure control

- External adjustment

- Control panel type

- Integrated / Remote