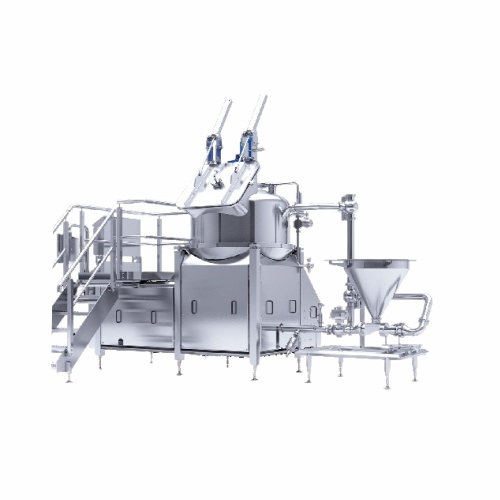

Lump-free emulsifier and steam batch cooker for processed cheese

Achieve consistent, lump-free processed cheese and creamy sauces efficiently with advanced emulsification and steam cooking, designed for rapid batch processing while ensuring product quality and repeatability.

Emulsifies and Steam Cooks Lump-Free Food Products

The ShearTherm from Natec Network is an innovative high-shear emulsifier and steam batch cooker designed specifically for food processing companies. Its modular design uniquely combines emulsification, cooking, and pasteurization in a compact footprint, offering exceptional adaptability for various food applications. Capable of processing up to 2,400 liters per hour, the ShearTherm optimizes product consistency by utilizing the patented M4E emulsifying technology to ensure lump-free results. This equipment is suitable for producing a range of end-products, including processed cheese slices, cream cheese spreads, soups, sauces, dressings, and vegan cheese. It features direct steam injection for effective heating and integrates seamlessly into existing systems with its CIP (Clean-In-Place) capability, reducing downtime and maintenance efforts. Constructed from AISI 316L stainless steel, the ShearTherm ensures long-term durability and compliance with hygiene standards, making it an ideal choice for manufacturers of baby food, specialty foods, and luxury pet food gravies.

Benefits

- Achieves consistent product quality and stability with precise control over processing conditions.

- Enhances production efficiency by maximizing yield and minimizing raw material waste.

- Lowers operational costs through reduced energy consumption and maintenance requirements.

- Ensures hygienic production with fully enclosed CIP-able design for quick cleaning.

- Offers flexibility in product development with customizable configurations and rapid batch cycles.

- Applications

- Soups, Sauces, Plant based, Specialty food, Pet food, Fruits, Processed cheese, Cream cheese, Dressings, Vegetables, Vegan, Baby food

- End products

- Organic baby food pouches, Alfredo sauce, Vegan cheese, Vegetable purees, Plant-based yogurt, Baby formula, Luxury pet food gravies, Cream cheese spreads, Tomato basil soup, Gourmet specialty spreads, Processed cheese slices, Ranch dressing, Fruit compotes

- Steps before

- Grinding, Transferring, Blending, Feeding, Ingredient Addition

- Steps after

- Packing, Cooling, Sterilization, Seamless Integration with UHT RotaTherm Cooker

- Input ingredients

- processed cheese ingredients, cream cheese ingredients, mayonnaise ingredients, plant-based ingredients, vegan ingredients, powder concentrates, fruits and vegetables, soups ingredients, sauces ingredients, dressings ingredients, baby food ingredients, specialty food ingredients

- Output ingredients

- lump-free processed cheese, lump-free cream cheese, lump-free mayonnaise, lump-free sauces, lump-free dressings, homogeneous plant-based products, vegan food products, stable emulsifications, high-quality baby food, specialty food products

- Market info

- Hochland Natec is known for manufacturing innovative engineered-to-order equipment and solutions for the dairy and food processing industry, specializing in cheese production and processing technologies, with a strong reputation for quality and innovation.

- Capacity

- Up to 2, 400L/h

- Batch size

- 150L, 300L, 600L

- Batch cycles

- Up to four batches per hour

- Heating temperature

- Up to 98°C (208°F)

- Voltage

- 400 V, 50 Hz, 3 phase

- Automation

- Full control with variable speed

- Material

- AISI 316L (1.4404) stainless steel

- CIP

- Fast CIP for maximum uptime

- Product type

- Lump-free (fine particle foods)

- Product homogenization

- 100% homogeneous and lump-free

- Pasteurization

- Capable

- Working mechanism

- High-shear emulsifier

- Integrated steps

- Emulsification, homogenization, pasteurization

- CIP principles

- Fast CIP through automatic programs

- Batch vs continuous operation

- Batch

- Automation level

- PLC-controlled

- Energy efficiency

- Reduced energy costs

- Repeatability

- High repeatability with variable speed control

- Footprint

- Compact modular design

- Cleanability

- Easy CIP through automatic programs

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Feed/discharge method

- Integrated system

- Tank size

- 150L / 300L / 600L

- Material of construction

- AISI 316L stainless steel

- Control panel type

- Modular

- Pre-mixer and agitator type

- Multi-directional

- Vacuum system

- Integrated

- Control panel type

- HMI with touch interface

- Integration possibilities

- Seamless integration with existing CIP system

- Footprint customization

- Modular design

- Batch size options

- 150L to 600L

- Homogenisation unit speed control

- Variable

- Steam conditioning unit

- Available

- Powder and ingredient addition systems

- Available

- Discharge and CIP pump

- Combined

- Direct steam injection

- Included

- Bin lifter for ingredient addition

- Available