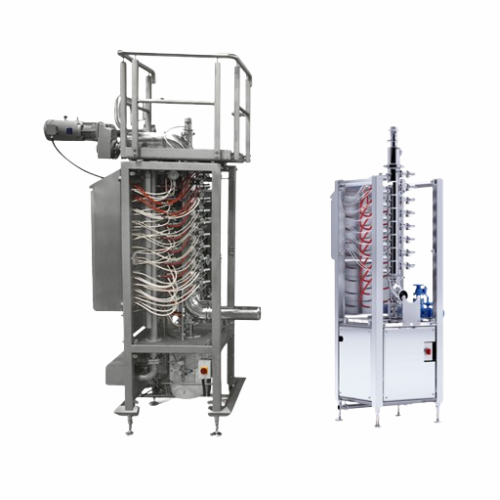

Continuous cooker for high-volume food processing

Elevate your production efficiency with a continuous cooker that ensures rapid, even heating and high product yields, minimizing waste and operating costs for large-scale food processing.

Cooks and Pasteurizes Diverse Food Products

The RotaTherm® Continuous Steam Cooker System from Natec Network revolutionizes large-scale food processing by delivering rapid, even cooking and pasteurization ideal for a wide range of products, from processed cheese to pet food. Utilizing unique steam fusion technology with multiple injector points, it supports processing capacities up to 17,000 kg/h for high efficiency and quick return on investment. Designed for a continuous and automated workflow, the system integrates seamlessly into production lines, reducing manual intervention through PLC-controlled operations and offering optional blending, feeding, vacuum cooling, and de-aeration systems. Constructed from materials compliant with stringent food industry standards, it employs a Clean-In-Place system, minimizing maintenance downtime. Its flexible processing parameters accommodate pasteurization, Ultra High Temperature (UHT), and aseptic needs, making it versatile for producing liquid, solid, and slurry food types across various industries.

Benefits

- Increases production efficiency with continuous operation up to 156 hours between cleanings.

- Enhances product quality by ensuring consistent cooking and nutrient retention through steam fusion technology.

- Reduces operational costs with low waste output and energy-efficient processes.

- Adapts to diverse product requirements, supporting pasteurization, UHT, and aseptic processing.

- Minimizes maintenance downtime with integrated Clean-In-Place system.

- Applications

- Meat products, Soups, Sauces, Mozzarella, Pasta filata, Vegan foods, Specialty food, Pet food, Fruits, Processed cheese, Cream cheese, Dressings, Vegetables, Baby food, Plant based products

- End products

- Alfredo sauce, Infant cereal, Tomato soup, Mozzarella sticks, Vegan cheese, Canned peaches, Steamed carrots, Sausages, Ricotta cheese, Tofu, Provolone cheese, Cheddar cheese, Dog food, Ranch dressing, High-protein snacks

- Steps before

- Grinding, Blending, Feeding, Transferring, Forming

- Steps after

- Forming and portioning, Separating, Vacuum cooling, De-aeration, Packing

- Input ingredients

- processed cheese, cream cheese, mozzarella, pasta filata, soups, sauces, dressings, meat products, plant based ingredients, vegan ingredients, fruits, vegetables, baby food ingredients, specialty food ingredients, pet food ingredients

- Output ingredients

- cooked processed cheese, cooked cream cheese, cooked mozzarella, cooked pasta filata, cooked soups, cooked sauces, cooked dressings, cooked meat products, cooked plant based foods, cooked vegan foods, cooked fruits, cooked vegetables, cooked baby food, cooked specialty food, cooked pet food

- Market info

- Hochland Natec is known for manufacturing innovative engineered-to-order equipment and solutions for the dairy and food processing industry, specializing in cheese production and processing technologies, with a strong reputation for quality and innovation.

- Capacity

- 50 - 17, 000 kg/h (110 - 37, 500 lb/h)

- Capacity for meat rendering

- 20, 000 kg/h (44, 000 lb/h)

- Run time

- Up to 156 h between CIP cleans

- Heating temperature

- 40 - 145 °C (104 – 293°F)

- Utilities

- Steam, air, water, and power as required

- Working mechanism

- Continuous steam cooking

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- Highly automated with choice of operating systems

- Clean-In-Place (CIP)

- Up to 156 hours non-stop between CIP

- Processing flexibility

- Handles diverse products, viscosities, compositions

- Efficiency

- Lowest operating cost, fastest ROI

- Heating method

- Unique steam fusion technology

- Simple to use

- One-touch START, STOP and CLEAN

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Varies (useful for processed cheese, sauces, purees, etc.)

- Machine footprint

- Varies by system size

- Feed/discharge method

- Conveyor system

- Construction materials

- Food-grade stainless steel

- Control panel type

- One-touch START, STOP and CLEAN

- Automation level

- Highly automated with choice of operating systems

- Integration possibilities

- Stand alone or integrated into CIP system

- Discharge method

- Vacuum cooling and de-aeration systems