Dried Fruit Equipment

Find innovative production technology for making dried fruit and connect directly with world-leading specialists

Fruit dehydration is the earliest form of food preservation, with the earliest written record of dried fruits dating back to ancient Mesopotamian tablets, which contain the world’s earliest known recipes. Today, some of the most popular dried fruit snacks are raisins, dates, mango, pineapple, prunes, figs and apricots. Dried fruit processing equipment helps preserve the nutrients and sweetness of the fruit and prolongs its shelf life.

Select your dried fruit process

Tell us about your production challenge

Dehydration methods and dried fruit processing equipment

Many techniques of dehydrating fruit/vegetables developed throughout centuries, including sun drying, vacuum drying, spray drying, fluid bed drying, microwave and freeze-drying.

Sun drying is undoubtedly one of the oldest techniques of fruit drying. It relies on the sun’s thermal power and dry air. This process of food drying is usually lengthy and exposes the fruit to various contaminants like insects and microorganisms. To speed the process up and maximize solar energy, manufacturers use black-painted trays, solar trays, mirrors and collectors. As well as other stainless steel food grade pieces of equipment.

Atmospheric dehydration is a more modern method and is widely used in dried fruit manufacturing. It incorporates the use of hot, dry air in a stationary or continuous process. For this method, you need dried fruit processing equipment like cabinet driers or tunnel driers. Freeze-drying, or lyophilization is based on the sublimation principle. It applies low temperature and pressure to vaporize the water/ice in the fruit. Freeze-dried fruit retains all its nutrients as well as its structure. This cooled dried freezer method is mostly used on sensitive fresh fruit with a weaker structure and high water content, like strawberries and raspberries.

Prepping and sulfuring the fruit

Fruit needs to be prepped before drying and the basic steps of the pre-drying process are selection, sorting, washing and, in some cases, peeling and cutting the fruits. Another important step in the pre-drying process is color preservation, commonly known as sulfuring. Most fruits are treated with sulfur dioxide (SO₂), which slows the deterioration of the fruit’s browning, which happens when enzymes are not inactivated by the heat used during drying. Moreover, it helps preserve the carotene and ascorbic acid found in the fruit.

Sulfur dioxide is used widely in dried fruit manufacture, but it is good to note that it can negatively affect people with asthma if they ingest it in large quantities. The FDA, for example, requires food and snack manufactures to disclose the presence of sulfiting agents on the label if it is in concentrations of at least 10 parts per million.

Freeze-dried vs dehydrated fruit

While dehydrated fruit still has about 30% of its initial moisture, freeze-dried fruit retains only 1 to 4% of its original moisture. The water content gives the dehydrated fruits a chewy and sweet texture. On the other hand, the freeze-drying method leaves tiny air pockets in the fruit creating a light, crispy texture in it. This happens because the water escapes from the fruit in the form of gas.

The difference in water content also impacts the shelf life of dehydrated fruit and manufacturers usually add preservatives to prolong it. Contrastingly, freeze-dried fruit does not need additives because of its low moisture content and can last longer. Due to the heating process, dehydration can remove the nutritional content from the fruit. However, although the freeze-dried fruit process preserves all of the fruit’s original, it is a more expensive process and requires special packaging to minimize oxidation

Regulations and international standards for dried fruit

There are important regulations and international standards all manufacturers of dried fruit must comply with in order to export and sell their products.

Strict controls are implemented on the amount of aflatoxins. The FDA requires that levels of aflatoxins for nuts and dried fruit be below 2 μg/kg for aflatoxin B1, and below 4 μg/kg for the total aflatoxins content.

In Europe, all additives must be approved and contaminants like mycotoxins and pesticide residues are banned. The European Commission also has regulations on the maximum residue levels for chlorate and perchlorate. The maximum allowed level of chlorate is 0.3 for dates and figs and 0.05 mg/kg for most other fruit and vegetables. For perchlorate the maximum is 0.05 mg/kg.

In both the US and the EU deem sulfur dioxide safe for human consumption, but it is considered an allergen in the EU. Sulfur dioxide and sulfites must be clearly labeled and highlighted.

Conductive multi-flash drying method

Food scientists Jade Varaschim Link, Giustino Tribuzi, João Borges Laurindo published in the Journal of Food Processing and Preservation a new study for fruit drying in 2017. The study stems from the fact the short shelf life of some fruits limits their commercialization as fresh products. Their study focused on the drying process as well as the physical and structural properties of their samples and how they reacted to different drying methods. They also compared nutritional and rehydration properties of dried fruit.

KMFD, or conductive multi-flash drying, uses multiple cycles of heating-vacuum pulse to dry fruit. This method heats the fruit at atmospheric pressure to 60°C before applying a vacuum pulse (sudden decompression). The scientists used a vacuum drying chamber and connected it to a vacuum pump, while samples were laid on plates that were heated with electrical resistances.

KMFD-treated fruit developed a crispy-and-dried texture and retained its color, shape and nutrients in shorter time compared to freeze-drying, air-drying and vacuum drying.

Processing steps involved in dried fruit making

Which dried fruit technology do you need?

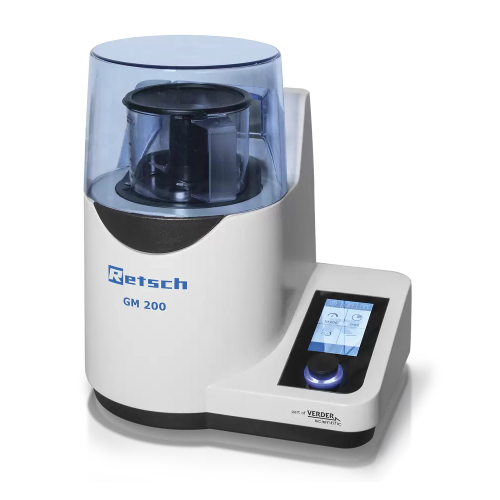

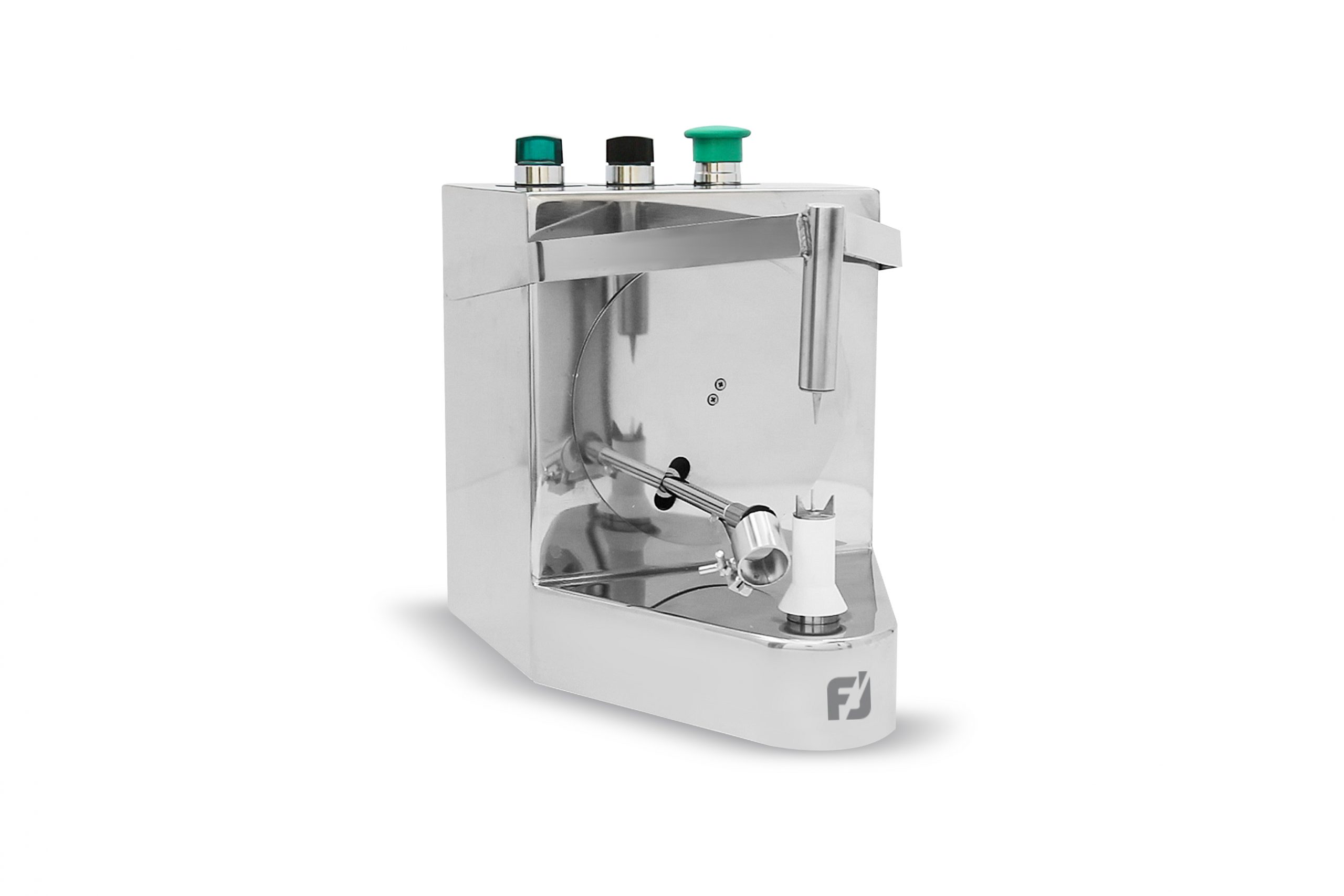

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

High efficiency milling solution for pharma and food industries

Achieve precise particle size control and enhance produc...

Cone mill for size reduction

Achieve precise particle size reduction and deagglomeration with minimal heat generation, ensur...

Coating solution for nuts and dried fruits

Easily apply multiple layers of chocolate to nuts, coffee beans, and more, achi...

Chocolate coating system for nuts and small biscuits

Effortlessly achieve consistent chocolate coatings on nuts, fruits, ...

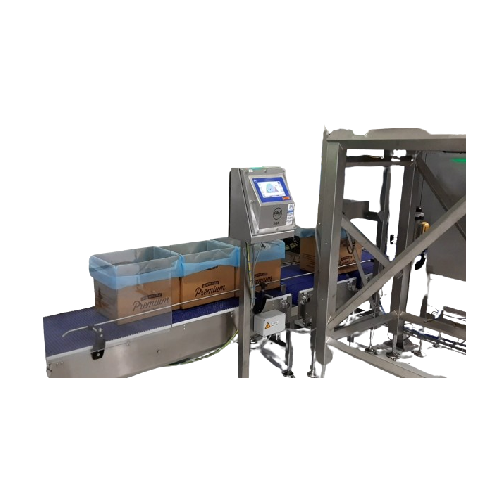

Box weight checkweigher for bulk bag-in-box applications

Ensure precise weight control in bulk packaging lines with this ...

Linear vibratory weigh filler for fragile food products

Achieve precise and gentle filling of fragile food products with ...

Industrial Xl bag sealer for large pallet containers

Eliminate manual handling and ensure perfect seals for bulk packagin...

Linear weigh filler for accurate box packaging

Ensure precise weight-based filling for a variety of solid products, from d...

Roasting and pasteurization system for nuts and seeds

Ensure optimal pasteurization and roasting of nuts, seeds, and drie...

Roasting and pasteurization solution for nuts and seeds

Optimize your product line with seamless blending and pasteurizat...

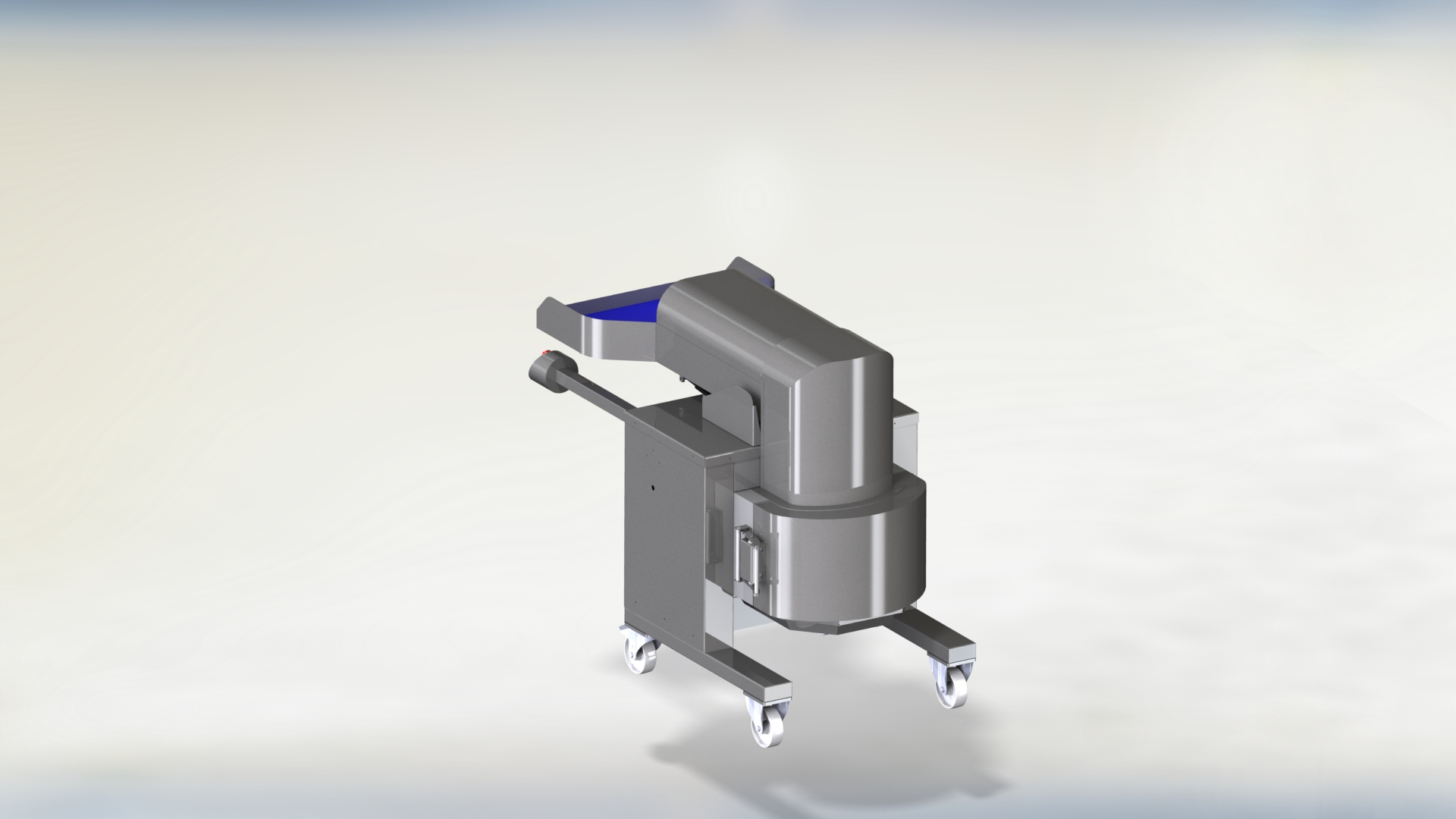

Food cutter for professional kitchens

Optimize your food preparation with precision mincing, cutting, and homogenizing, pre...

Professional food cutter for various ingredients

Streamline your food preparation with a versatile cutter designed to effi...

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

X-ray food inspection system for loose products

Ensure contaminant-free loose products by integrating a versatile inspecti...

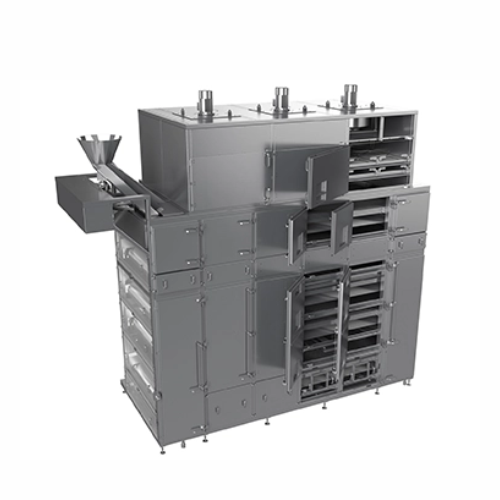

Industrial food dehydrator for fruit and vegetables

Optimize your drying process with a high-temperature food dehydrator ...

Vegetable and fruit cutting solution for slices, segments, and sticks

Streamline your pre-processing with a versatile c...

Industrial raisin washing system

Achieve thorough cleaning and separation for small, high-density food products with this in...

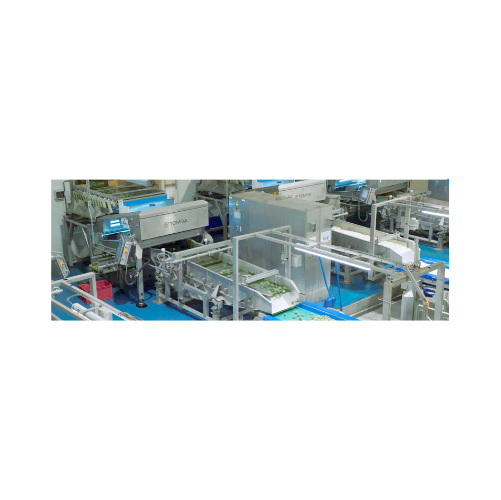

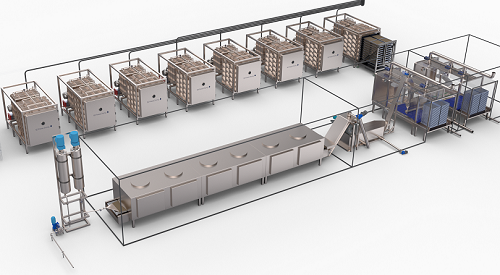

Fruit processing and packaging line

Streamline your fruit and vegetable processing with this semi-automatic system designed...

Grape destemming solution for efficient fruit processing

Streamline your fruit preparation process with a versatile machi...

Industrial fruit drying cabinet

Efficiently transform fresh produce into long-lasting, nutrient-dense snacks with precise dr...

Rotary size grader for food processing

Enhance your production line by efficiently sorting and classifying produce to ensur...

Small piece remover for food processors

When handling diverse food products, ensuring consistent product sizing is vital. T...

Tote bin dumper for bulk product transfer

Streamline your bulk product handling with a solution that efficiently transfers...

Industrial transfer conveyor system

Efficiently transport and sort diverse food products with precision, ensuring seamless ...

High-performance food processing and sorting solutions

Optimize your production line with integrated processing, conveyin...

Food processing mixing system for vegetables

Tackle complex product mixing challenges with a system that seamlessly integr...

Optical sorting platform for food processing

For manufacturers aiming to enhance quality control, this platform offers pre...

Optical sorter for blueberries

Enhance product quality and yield by precisely sorting blueberries, ensuring only optimal fru...

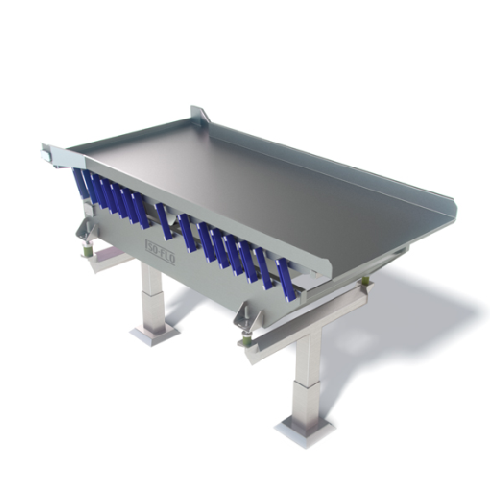

Large capacity horizontal motion conveyor for fragile products

Achieve gentle handling and minimize product damage with ...

Optical sorter for food processing

Enhance your production line with advanced sorting technology that meticulously inspects...

Distribution conveyor systems for food processing

Streamline your food processing pipeline with precision-engineered dist...

Feed conveyors for efficient product presentation

Optimize your production line with feed conveyors designed to streamlin...

Hydro-flo food processing pump for vegetable transfer

Optimize food handling with a gentle, space-saving pump that protec...

Industrial food grading system for vegetables

Optimize your production line with a versatile food grading system, ensuring...

High-capacity optical sorter for food processing

Optimize your production line with precise sorting and separation, enhanc...

Optical potato sorter

Ensure precise sorting with advanced optical technology that identifies and separates defects in a wide...

Optical sorting solution for food processing

Achieve precise sorting and maximize yield with a cutting-edge optical soluti...

Sorting system for blueberries

Streamline diverse food processing tasks by efficiently conveying, processing, and sorting pr...

Vibratory conveyor for efficient bulk material transportation

Optimize your processing line with robust vibratory convey...

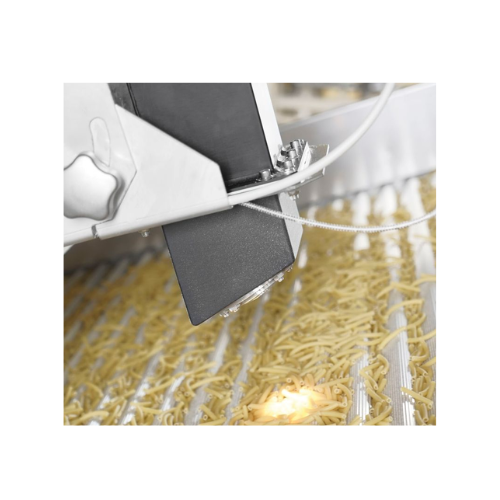

Automatic defect removal for french fries

Maximize yield and enhance quality in potato strip production with precision cut...

Inspection systems for poultry and seafood processing

Enhance the quality control of your food production with cutting-ed...

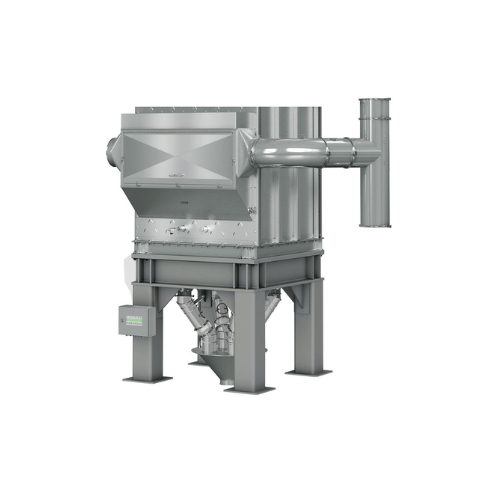

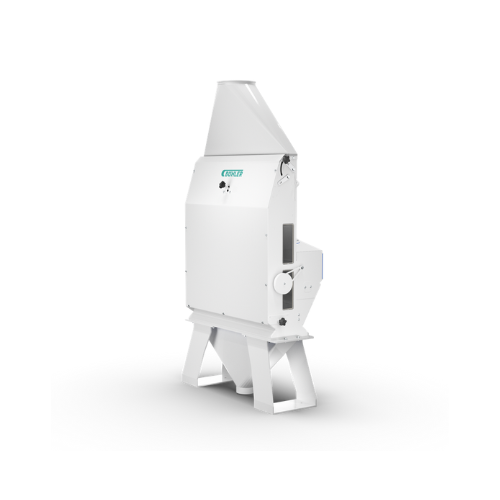

Industrial air cleaner for food processors

Optimize your production line with high-speed air separation, effectively remov...

Collection conveyors for food processing

Optimize your production line by efficiently collecting and conveying solid produc...

High-speed centrifugal sifter for food and pharma applications

Optimize your powder processing with a high-speed centrif...

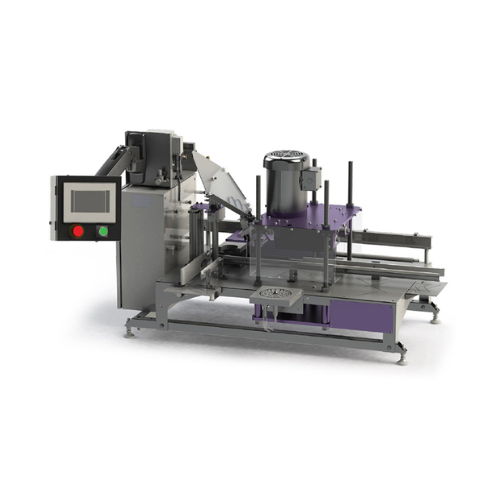

Vertical dosing and filling solution for confectionery packaging

Optimize your confectionery and nutraceutical packaging...

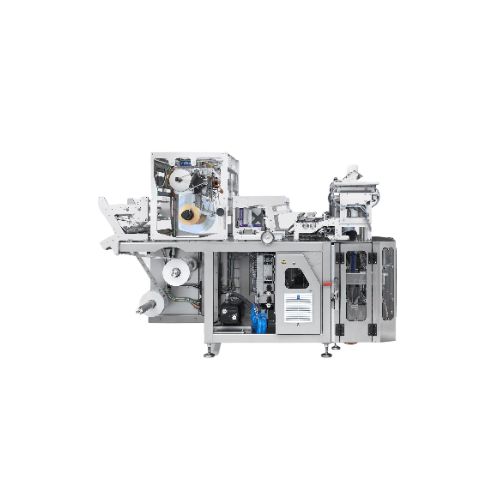

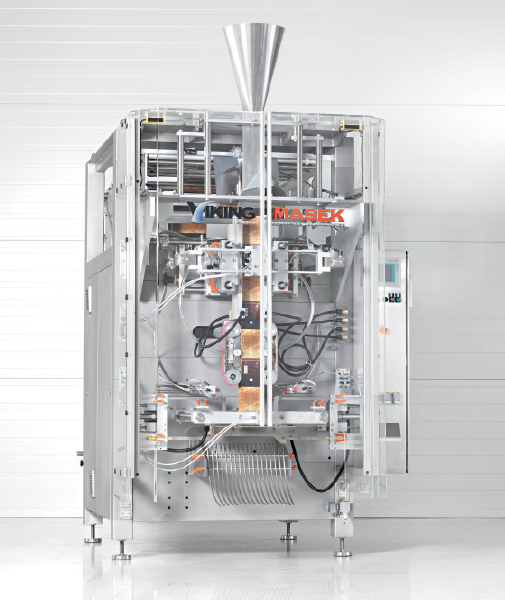

Intermittent vertical form fill seal for confectionery packaging

Optimize your packaging operations with this versatile ...

Continuous vertical form fill seal packaging solution

Experience unrivaled accessibility and efficiency in packaging fres...

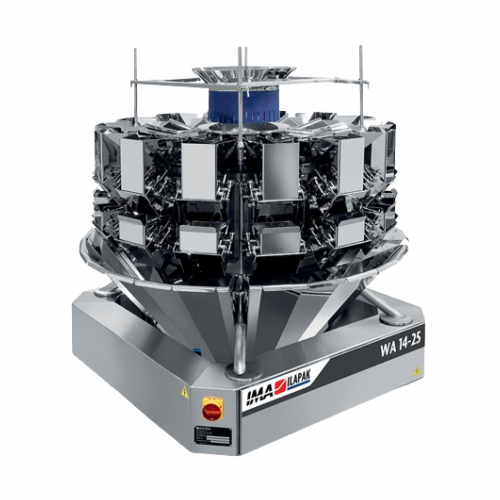

High precision multihead weigher for confectionery production

Achieve precise weighing and counting for varied product c...

Ultra-fine grinding jet mill for coarse and fibrous materials

Effortlessly achieve ultra-fine particle sizes in coarse a...

In-line seal checker for high-speed snack packaging

Ensure flawless package integrity with in-line leak detection, enhanc...

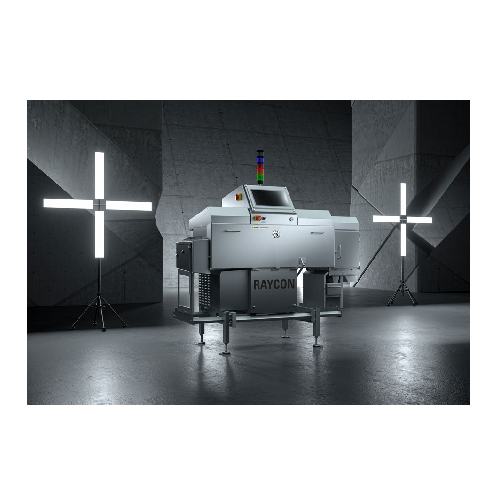

X-ray inspection system for identifying foreign bodies in food products

Ensure precise detection of foreign materials i...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

Plantain and banana chip fryer

Achieve consistent, high-quality plantain and banana chips with a continuous fryer designed f...

Oil cooling module for industrial fryers

Quickly cool frying oil to prevent thermal shock and maintain oil quality, allowin...

Continuous french fry fryer

Achieve optimal frying conditions with precise temperature control and rapid load adjustments, e...

Incline transfer conveyors for dry, fresh, and frozen food products

Efficiently transfer a variety of solid and granule...

Flexible fryer for various snack products

Optimize your snack production with a fryer that adapts to varied product requir...

Industrial water removal system for food preparation

Enhance your production line with advanced surface water and starch ...

Batch frying system for kettle-style potato chips

Achieve consistent, high-quality kettle-style potato chips with a syste...

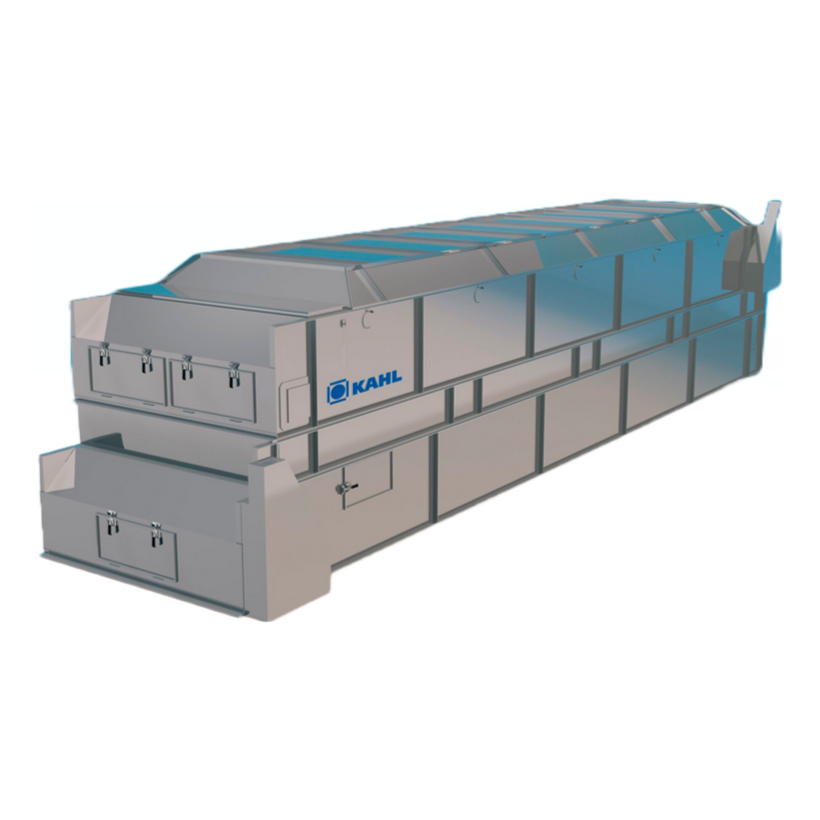

Industrial tunnel dryer

Optimize drying efficiency and maintain product quality with continuous tunnel drying, ideal for prec...

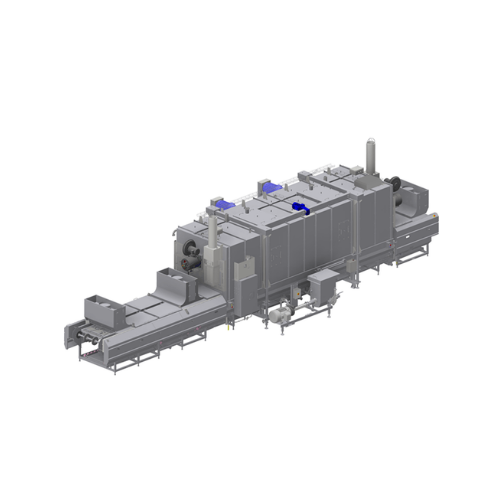

Continuous tunneling drying system for industrial applications

Streamline your drying process with precision-controlled ...

Industrial sludge drying solution

For facilities needing precise moisture removal, this compact solution ensures efficient ...

Drum dryer for animal feed

Achieve efficient and uniform drying for a variety of products, from nuts to medicinal cannabis, ...

Continuous dryer for large production volumes

Achieve high-speed moisture removal with precision and minimal thermal impac...

Continuous belt dryer for industrial production

For operations requiring precise moisture control, this continuous belt dr...

Flat-belt slicer for fruits and vegetables

Optimize your slicing process with a solution that delivers precision cuts whil...

Vegetable and fruit centrifugal slicer and shredder

Enhance your food processing with high-capacity slicing and shredding...

Pulsed electric field treatment for roots, tubers, and fruits

Enhance your production line with advanced pulsed electric...

Vacuum and freeze drying plants for food and pharmaceuticals

Ensure high-quality, extended shelf-life products with inno...

General purpose freeze dryer for small commercial batches

Maximize your production line’s flexibility with this ve...

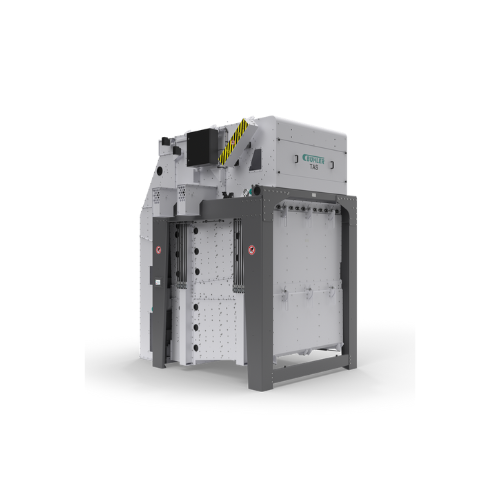

Grain cleaning system for high-quality processing

Optimize your grain processing with a versatile cleaning system designe...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

Multi-pass pet food dryer for consistent moisture content

Achieve precise moisture control and enhanced product quality ...

Optical sorter for coffee, grains, nuts, and plastic flakes

Ensure precise defect detection and foreign material removal...

Optical sorter for nuts or dried fruits

Ensure maximum food safety and quality by efficiently sorting and removing shells, ...

Optical sorter for frozen fruit and vegetable processing

Enhance your processing line’s efficiency with high-speed ...

Batch mixer for animal feed

Streamline your mixing process with a high-speed batch mixer that delivers up to 20 mixing cycle...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Commercial pasta press for diverse ingredients

Optimize your pasta production with a flexible solution capable of handling...

Scraped surface heat exchanger for viscous liquids

Optimize heating and cooling of viscous liquids efficiently with conti...

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

Sieve tensioning device for milling applications

Achieve precise and consistent tensioning across various sieve frames wit...

Impact machine for milling applications

Optimize your grain processing with this versatile impact machine, designed to refi...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Industrial grain flaking mill

For efficient grain processing, achieve uniform flake quality with advanced temperature-contro...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

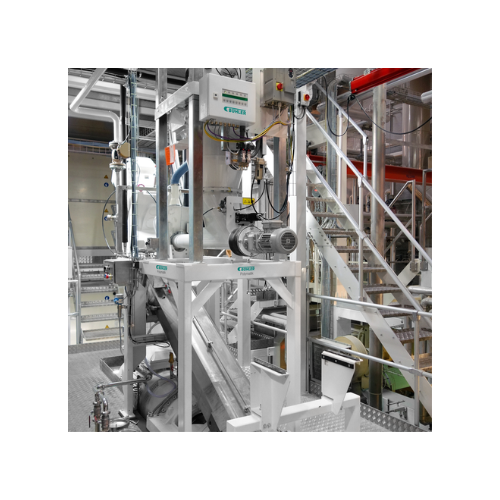

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Optical sorter for grain and seed sorting

Ensure precise defect detection and efficient sorting of grains, pulses, and see...

Digital process service for regulating water in dough preparation

Achieve consistent dough moisture levels with this di...

Optical sorter for wheat applications

Effortlessly enhance product purity by eliminating color defects and foreign material...

Aspiration channel for grain cleaning

Achieve superior product quality by efficiently removing light impurities from granul...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Industrial cooling die for wet textured proteins

Maximize production efficiency by creating diverse, high-quality protein ...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Ultra-fine pulverizer for aqua feed and pet food

Achieve precise granulation with high efficiency for your feed and food p...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Vibrating tables for dewatering and sizing

Optimize your processing line with versatile vibrating tables designed to effic...

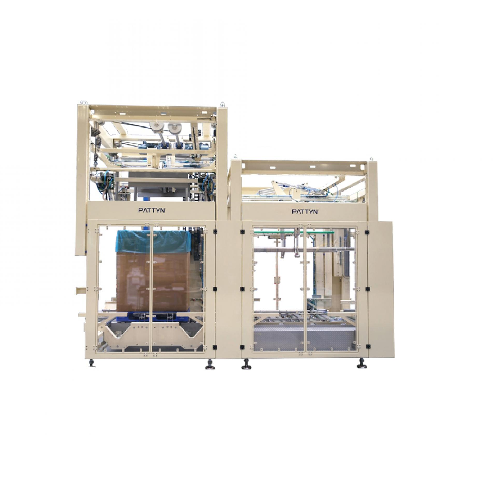

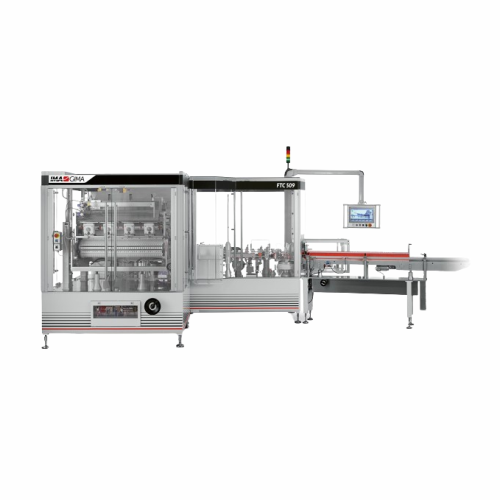

Semi-auto case packer for flexible bag collation

Enhance your manual packing speed and flexibility with a semi-automatic s...

Industrial clean-in-place (cip) system

Ensure seamless cleaning and sanitation in your production line with innovative CIP ...

Surface pasteurizer for low moisture foods

Ensure a pathogen-free surface on low moisture products without altering their ...

Single pass dryer for fresh produce

Optimize your fresh produce processing with a continuous drying solution that enhances ...

Industrial vibrating extractor for homogeneous product conveyance

Ensure consistent flow of dry bulk materials with a v...

Vertical form-fill-seal for pillow bag packaging

Looking to enhance the speed and reliability of your packaging process? T...

High-speed vertical packaging system for candy and snacks

Achieve up to 500 pillow bags per minute with our high-speed p...

Vertical form fill sealer for high-speed packaging

Achieve consistent, high-speed packaging with flexible bag styles, per...

Industrial fruit washing and loading hopper system

Streamline your juice production by ensuring optimal fruit preparation...

Solid product feeding systems for food industry

Ensure consistent product flow and maximize filling efficiency in your pro...

High-speed vertical form fill seal for various packaging needs

Streamline your packaging process with an advanced vertic...

Vertical form fill seal for bulk bag packaging

Streamline your bulk bag packaging with efficiency and precision, ideal for...

Industrial dicer for small to intermediate size ranges

Boost your production capacity with a versatile dicing solution th...

Compact food dehydrator with Bpa-free trays

Achieve precise dehydration with compact, kitchen-friendly equipment, perfect ...

Compact food dehydrator for fruits and meats

Achieve precise dehydration of fruits, vegetables, and meats with a compact s...

Food dehydrator with Bpa-free trays

Effortlessly retain nutrients while creating a variety of dehydrated snacks using dual ...

Food dehydrator with Bpa-free plastic trays

Achieve precise dehydration for fruits, vegetables, and snacks with advanced t...

Food dehydrator with stainless steel trays

Achieve optimal dehydration with precise temperature control and efficient dual...

Low temperature food dehydration system for fruit and vegetables

Optimize your food processing with advanced low-tempera...

Professional food dehydrator for fruits and vegetables

Enhance your culinary creations with precise dehydration technolog...

High-precision sorter for nuts, coffee, seeds, and grains

Achieve unrivaled accuracy in sorting nuts, seeds, and grains ...

Optical sorter for nuts, dried fruit, and Iqf

Ensure flawless quality control by efficiently sorting, grading, and ejectin...

Optical sorter for nuts and dried fruit

Enhance sorting precision by effortlessly identifying and removing foreign material...

Advanced fruit sorting platform

Optimize your operations with a cutting-edge sorting solution designed to enhance product in...

Food sorting system for nuts and dried fruit

Streamline sorting processes by removing visual irregularities, defects, and ...

Dry bin filling for delicate fruit

Achieve gentle, high-throughput filling of delicate fruits with minimized manual interve...

Single and dual lane sorters for fresh produce

Optimize your food processing line with precision defect detection and vers...

Blizzard sorter for Iqf fruits and vegetables

Optimize your frozen food production with a compact sorter that seamlessly r...

Cherry singulation system

Effortlessly streamline cherry processing with a system that ensures gentle handling and superior ...

Cherry sorting system with deep learning technology

Boost your fruit processing efficiency by utilizing advanced deep lea...

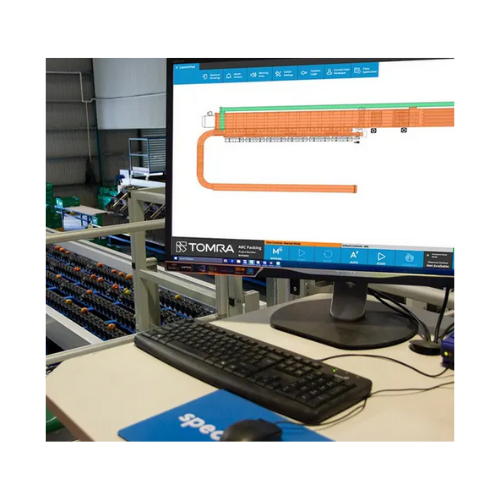

Line control and product tracking systems for post-harvesting

Optimize your production line with precision control and r...

Modular packing system for multihead weighing

Streamline your production with a versatile multihead system designed for pr...

Ventilation and dehumidification for meat processing plants

Achieve precise humidity and condensation control in meat pr...

Industrial strawberry and blueberry washer

Ensure your soft fruits remain intact and impurity-free with this specialized w...

Mesh belt food dryer

Achieve uniform and efficient drying of diverse materials with the mesh belt food dryer, designed to max...

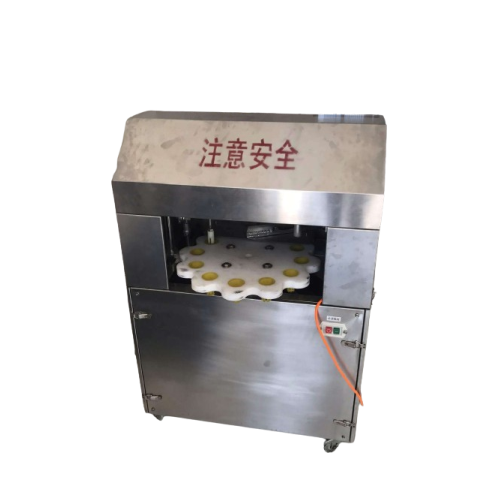

Jujube pitting and nut removing solution

Streamline your fruit processing with this efficient solution designed to remove p...

Commercial mango dehydrator

Optimize your fruit processing with a commercial mango dehydrator that ensures precise moisture ...

Fruit and vegetable drying equipment

Achieve optimal moisture control for your fruits, vegetables, and herbs with versatile...

Date palm processing line for jujube cleaning and drying

Optimize your date and fruit production with our line that ensur...

Vegetable and fruit air drying production line

Efficiently dry fruits, vegetables, and vacuum-packed goods while maintaini...

Stationary drying system for agricultural products

Optimize moisture control and energy efficiency in your drying process...

Semi-automatic fruit and vegetable slicer

Optimize your fruit and vegetable processing with precise cutting capabilities, ...

Nut clusters moulding solution

Streamline your production line with efficient nut cluster moulding, ensuring precise shape a...

Flavour and colour dosing system

Simplify production by efficiently incorporating various flavors, colors, and solid inclusi...

In-line metal detector for liquids & pastes

Ensure product safety by seamlessly integrating a metal detection system into ...

In-line metal detector for pneumatic systems

Ensure product purity and operational efficiency with a solution that effecti...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

X-ray inspection system for unpackaged bulk products

Ensure product purity and safety in high-speed production lines with...

Nuts paste refining mill

Transform nuts and dried fruits into fine pastes with precise particle control, ideal for creating p...

Chocolate and sugar coating system

Achieve consistent, high-quality coating for nuts, dried fruits, and confectionery with ...

Industrial nut crusher for dried fruit processing

Optimize your nut and dried fruit processing by reducing them to precis...

Industrial cocoa nib grinder for bean to bar production

Streamline your chocolate production with this versatile grinder,...

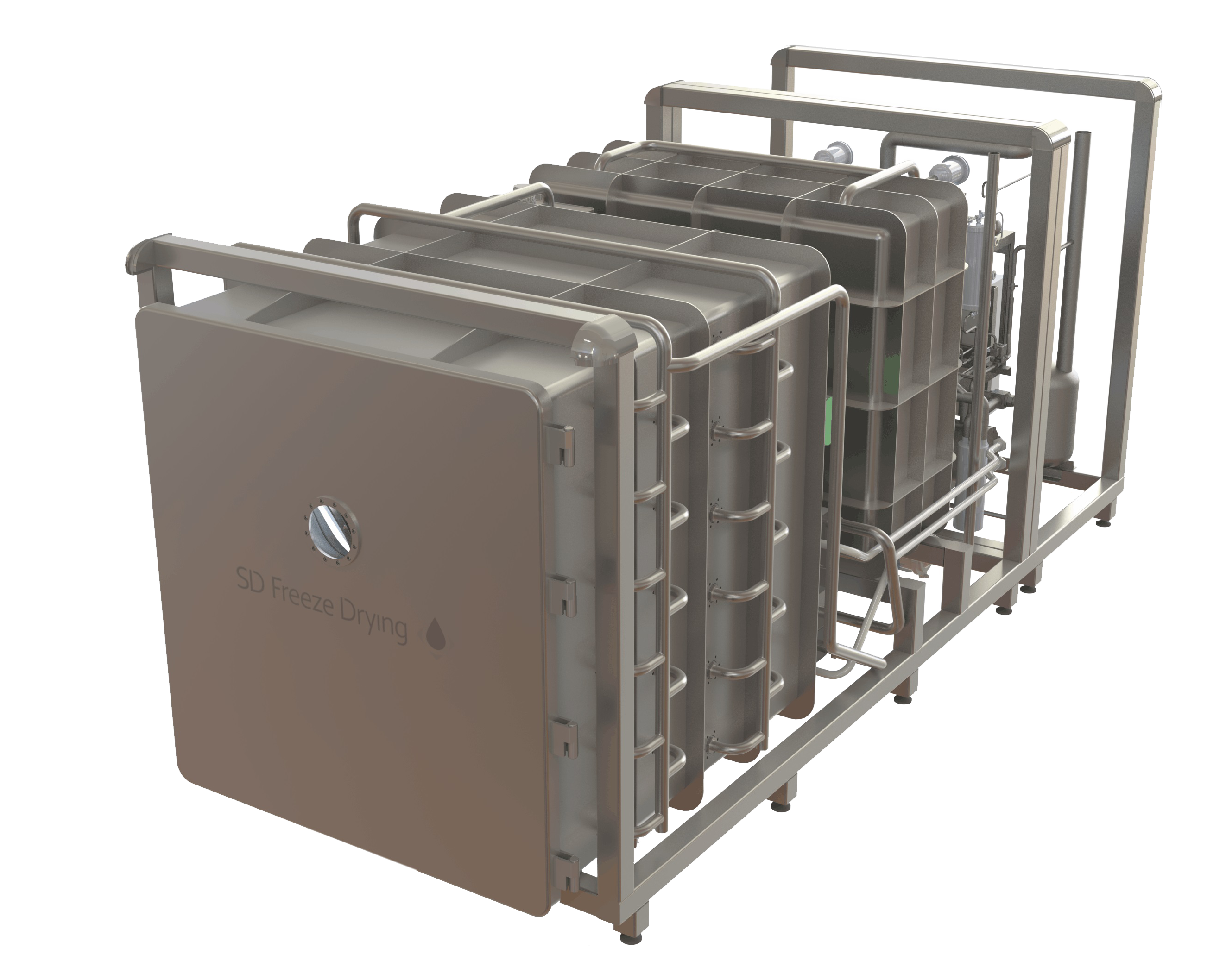

Semi-continuous freeze dryer with easy-loading

Freeze-drying is both a time- and energy-consuming process. In addition to ...

Freeze drying system for berries and fruit powders

Delicate fruits with high moisture levels, such as berries, risk losin...

Automatic Peeler Machine For Fruits and Vegetables

Manually peeling fruits and vegetables can be tedious. Especially in l...

Case packer machine for pouches

Automated case packer machines are a good solution to achieve reliability and to increase th...

Mini sugar coating machine

The coating of grains or nuts with sugar is a popular process in the manufacture of many bakery p...

Industrial drying cabinet

The production of high-quality biltong and similar dried meat products can pose problems with main...

Pilot scale freeze dryer

Freeze drying is a complex and time-consuming drying process which requires maintaining the quality ...

Industrial food freeze dryer

Nutraceuticals and dietary supplements can be highly sensitive and need to be protected against...

Automatic freeze drying system

Freeze drying can be an expensive and cumbersome process. When dealing with nutraceuticals it...

Hygienic vertical bagging machine

Hygienic bagging with a compact packing machine that can withstand the harshest wash down...

Recirculating batch dryer

Drying can be the most energy and time-consuming process in the food industry. This can have an ef...

Continuous dryer machine

Traditional drying methods in the pet food, aquafeed, and extruded food industry can be the most ene...

Standalone metal detector for food

Adding advanced metal detection to existing lines can be difficult and expensive, often ...

Industrial dehydration machine

Dried fruits are popular both as food in themselves and as ingredients. Traditional drying te...

Optical sorter for dried and frozen fruits

Dried fruits, frozen fruits, frozen vegetables and nuts present a challenge for...

Small scale dragee coating machine

Coated dragée products such as Jordan Almonds or hard-coated candies are very popular, b...

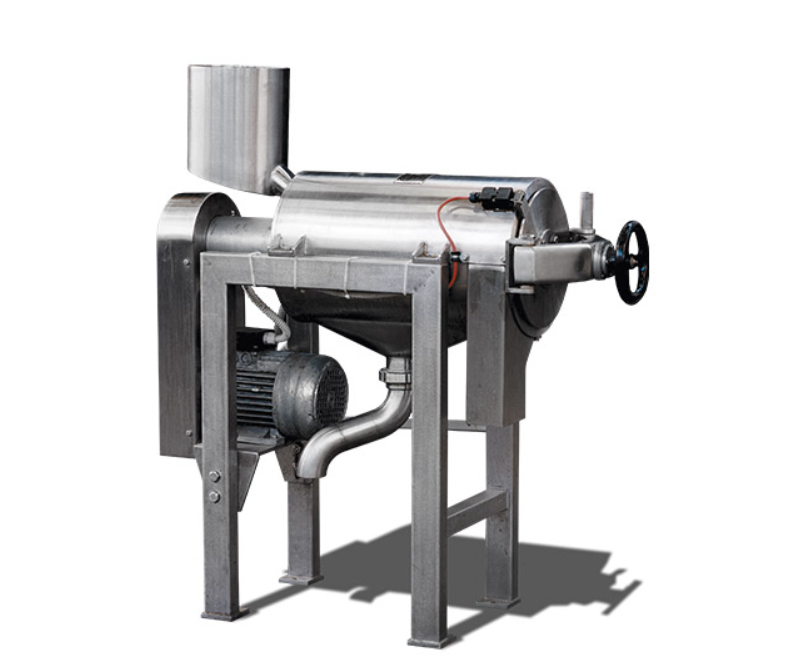

Fruit pulping machine

When making fruit pulp, a pulping machine helps you remove seeds, stems, and skins from your fruit. How...

Bagger with servo driven jaw actuation

If you want to accommodate multiple bag designs and dimensions with fast speed and a...

Packaging machine for sealed plastic bags from 250 g to 10 kg

Sealing small quantities of solids or liquids into plastic...

Declumping machine for dried fruit or frozen vegetables

Breaking up dried fruit neatly, without damage, requires gentle a...

Hygienic belt dryer

A belt dryer typically applies the product through an infeed chamber onto a perforated horizontal belt, w...

Air dehumidifier for bulk products

When your product or process is sensitive to humidity, using an air dehumidifier may res...

Metal detection system

The inspection system automatically determines the best frequencies to maximize sensitivity for both f...

High sensitivity X-ray inspection system

This is the X-ray inspection system you need for detecting contaminants that are d...