Optical sorter for nuts, dried fruit, and Iqf

Ensure flawless quality control by efficiently sorting, grading, and ejecting foreign materials from nuts, dried fruits, and IQF products, optimizing your production line.

Sorts and Grades Food Products Efficiently

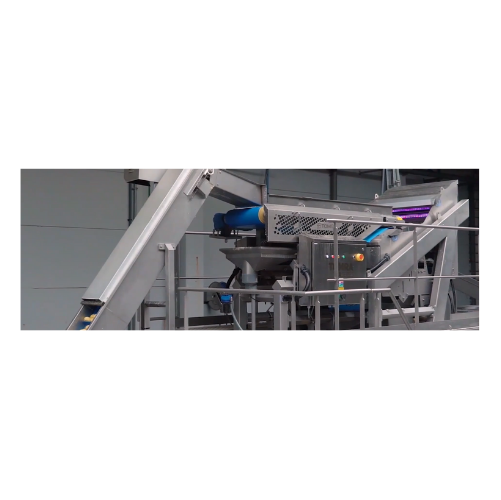

The TOMRA 5A Optical Sorter from TOMRA Food is designed to enhance efficiency and quality across various food processing lines. Specializing in sorting and grading applications, this equipment leverages cutting-edge optical technology to identify and remove foreign materials, misshapen, and discolored products. With applications ranging from nuts, dried fruit, and potatoes to IQF foods, TOMRA 5A optimizes production lines by ensuring consistent product quality and safety.

Operating at high speeds and with continuous processing capabilities, this sorter handles diverse end-products such as potato chips, raisin packs, IQF mixed vegetables, and shelled pistachios. The TOMRA 5A supports seamless integration with other line components, notably through its compatibility with the Peel Control Module for improved peeling efficiency and reduced waste.

Equipped with the TOMRA Insight data platform, the system enables remote monitoring and data analytics to unlock operational improvements and facilitate well-informed decision-making. Material options ensure durability in demanding conditions, and the design focuses on minimizing maintenance downtime, making it an invaluable asset for food processors looking to maximize throughput and product quality.

Benefits

- Ensures product safety and consistency by detecting and ejecting over 98% of foreign materials.

- Optimizes peeling processes to minimize waste through automated steam time adjustments.

- Enhances operational efficiency with continuous high-speed processing.

- Provides valuable production insights for decision-making via integrated data analytics platform.

- Reduces maintenance requirements, minimizing production line disruption.

- Applications

- Dried fruit, Potatoes, Protein, Confectionery, Nuts, Vegetables, Iqf (individually quick frozen foods), Seeds and grains

- End products

- Dried fruit medley, Pulses for soups, Potato chips, Almond snack packs, Shelled pistachios, Iqf bell peppers, Hazelnut confectionery, Peeled baby carrots, Cashew packs, Frozen spinach, Iqf peas, Iqf mango chunks, Pecans for pies, Iqf broccoli florets, Shelled walnuts, Dehydrated garlic, Raisin packs, Peeled peanuts, Fresh-pack potatoes, Iqf mixed vegetables, Iqf blueberries, Macadamia nut packs, Iqf strawberries

- Steps before

- Harvesting, Cleaning, Inspection

- Steps after

- Peeling, Cutting, Sorting, Packing

- Input ingredients

- potatoes, nuts, dried fruit, IQF products, apples, avocados, berries, cherries, citrus fruit, cranberries, kiwifruit, mangoes, olives, pineapples, raspberries, strawberries, tomatoes, almonds, cashews, hazelnuts, macadamias, peanuts, pecans, pistachios, raisins, walnuts, chips, dehydrated potato products, field potatoes, fresh pack potatoes, frozen potato products, potato specialties, meat, petfood, seafood, pulses, vegetables, beans, beets, bell peppers, broccoli, brussels sprouts, carrots, cauliflower, corn, dehydrated vegetables, garlic, green beans, spinach, leafy greens, mushrooms, onions, peas, peppers, pickles, radishes, seed corn, coffee beans, confectionery

- Output ingredients

- sorted potatoes, sorted nuts, sorted dried fruit, sorted IQF products

- Market info

- TOMRA is known for its expertise in sensor-based solutions for resource productivity, particularly in recycling, food sorting, and mining industries, offering advanced technology to improve resource recovery and efficiency, enhancing sustainability and operational performance.

- Sorting capability

- Whole, processed, and fresh foods

- Detection type

- Optical

- Automation

- High-performance 2- or 3- way sorting

- Capacity

- High capacity

- Removal rate

- Greater than 98%

- Data analytics and monitoring

- Remote monitoring with TOMRA Insight

- Automation level

- High/PLC Integrated

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP/SIP

- Energy efficiency

- High efficiency (e.g., 0.5–2 kWh/kg)

- Data connectivity

- TOMRA Insight data platform

- Remote monitoring capability

- Enabled

- Integration with peel control

- Available with PCM

- Detection and ejection system

- High precision with >98% removal rate

- Product quality consistency

- Ensured through automation and analytics

- Multi-step sorting capability

- 2- or 3-way sorting

- Biological compatibility

- Suitable for food contact materials

- Abrasion resistance

- High resistance to wear and tear

- Corrosive resistance (e.g. acids)

- Resistant to cleaning agents used in food processing

- Cleanability

- Designed for easy cleaning and sanitation

- Density/particle size

- Compatible with a range of densities

- Machine footprint

- Large, designed for high-capacity food processing

- Feed method

- Inline conveyor feed system

- Discharge method

- Automated ejector for sorted and defective products

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- Peel Control Module (PCM) / TOMRA Insight data platform

- Data analytics and remote monitoring

- TOMRA Insight