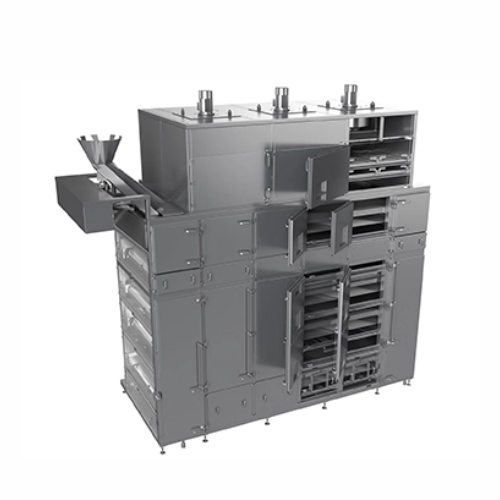

Continuous belt dryer for industrial production

For operations requiring precise moisture control, this continuous belt dryer offers a customizable solution, ensuring homogenous drying and optimal air distribution, even in high-volume production environments.

Dries and Dehumidifies Continuous High-Volume Products

The Bandtrockner from HARTER drying solutions is a fully automated belt dryer tailored for continuous high-volume applications. It utilizes advanced dehumidification technology, optimizing airflow to ensure uniform drying for diverse products like cornflakes, pet food pellets, and biosolids. The closed-system design minimizes air loss, enhancing system efficiency and reducing energy consumption. Suited for food, pharmaceutical, and sludge processing industries, it boasts precise parameter control, including adjustable belt speed and airflow patterns. Its robust construction supports heavy-duty operation, with material options like stainless steel ensuring durability and corrosion resistance. The system is designed for easy integration with existing production lines and features minimal maintenance requirements with options for in-situ cleaning. Compliance with industry standards makes it ideal for critical applications, supported by HARTER’s engineering expertise for custom solutions.

Benefits

- Seamlessly integrates into high-volume production lines, enhancing overall throughput.

- Optimizes energy usage by minimizing air loss through a closed-system design.

- Customizable air and speed parameters ensure precise moisture control for diverse products.

- Durable construction with corrosion-resistant materials prolongs equipment lifespan.

- Fully automated operation minimizes labor intervention and reduces operational costs.

- Applications

- Animal feed, Industrial sludge, Surface coatings, Sewage sludge, Packaging materials, Food products, Medicinal cannabis, Pharmaceuticals

- End products

- Gelatin capsules, Cornflakes, Cbd oil, Dried sludge cakes, Paint coatings, Pet food pellets, Shrink wrap film, Biosolids

- Steps before

- Purification, Grinding, Blending

- Steps after

- Sterilization, Packing

- Input ingredients

- Oberflächen, Lebensmittel, Tierfutter, Pharmazeutische Produkte, Medizinalcannabis, Verpackungen, Industrieschlamm, Klärschlamm

- Output ingredients

- Getrocknete Oberflächen, Getrocknete Lebensmittel, Getrocknetes Tierfutter, Getrocknete Pharmazeutika, Getrocknetes Medizinalcannabis, Getrocknete Verpackungen, Getrockneter Industrieschlamm, Getrockneter Klärschlamm

- Market info

- HARTER Drying Solutions is known for its expertise in energy-efficient drying technology, particularly using heat pump-based systems. They provide customized drying solutions for various industrial applications, focusing on energy savings and improved product quality.

- Band length

- Customizable per product

- Band speed

- Adjustable per process

- Drying capacity

- For large volumes

- Automated operation

- Fully automated

- Air circulation method

- Custom air guidance

- Temperature control

- Optimal temperature maintained

- System configuration

- Closed system

- Water removal calculation

- Controlled for openings

- Customization

- Tailored to product and throughput

- Working Mechanism

- Continuous Band Drying

- Automation Level

- Fully Automatic

- Closed System

- Minimized Openings

- Custom Airflow Control

- Product-Specific Airflow

- Temperature Optimization

- Product-Specific Settings

- Homogeneity of Drying

- Enhanced by Band Movement

- Throughput Adaptation

- Product and Volume Specific

- Machine footprint

- Varies with application

- Band length

- Customizable

- Band width

- Customizable

- Band speed

- Adjustable

- Discharge method

- Continuous/Batch

- Control panel type

- Customizable

- Feed/discharge method

- Automated

- System design

- Closed

- Fallstages and loosening systems

- Integrated if needed

- Shelving type

- Belt/Band

- Band length

- Customized

- Band speed

- Adjustable

- Airflow design

- Product-specific

- Fall stages

- Optional inclusion

- Schütthöhe (bulk height)

- Customizable

- Control panel type

- Customizable

- Closed system design

- Optimized openings