Industrial Canning Equipment

Find innovative canning equipment and connect directly with world-leading technology suppliers

Industrial canning is an important packaging step within the food processing industry for items such as beverages and tinned products. Automatic dosing and weighing systems portion out your product before distributing it into separate cans. A can seamer then folds the lid over the flange of the container, hermetically sealing the can. Some manufacturers opt for an additional plastic cap allowing consumers to re-close the can after the lid would have been peeled off.

What are you making?

Baking powder

Battered nuts

Beer

Canned beans

Canned cat food

Canned corn

Canned dog food

Canned fish

Canned fruits

Canned peaches

Canned soup

Canned tomatoes

Canned tuna

Cans

Carrots

Cashews

Cider

Condensed milk

Containers

Corn

Corn nuts

Craft beer

Dispersion paints

Dried fruit

Energy drinks

Evaporated milk

Fish

Fruit powder

Ground coffee

Luncheon meat

Milk powder

Paint

Peaches

Peanuts

Pears

Pineapples

Pistachios

Port silos

Roasted nuts

Soft drinks

Soup cans

Tea

Wet pet food

Which canning technology do you need?

Low output can filler for craft beer

For beverage producers looking to efficiently fill cans with precision, this versatile...

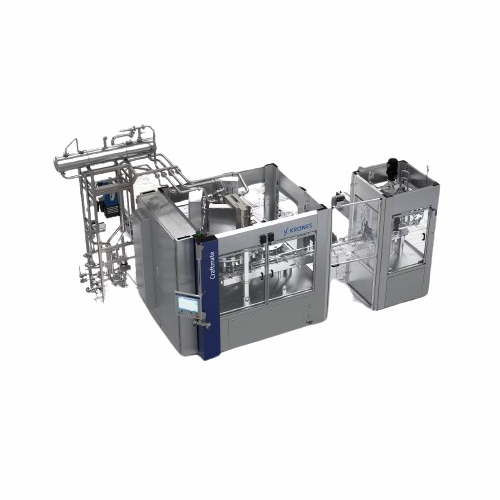

Automated beverage canning line

Optimize your beverage packaging with a high-speed canning line that seamlessly integrates f...

Powder can seamer for nutraceutical and beverage powders

Achieve precision and hygiene with this can seamer designed for ...

Horizontal Beverage Can Cartoner

Cans have many advantages over bottles when it comes to packing, for example, your craft be...

Hygienic bundles for can seaming equipment

Ferrum offers three hygienic bundles that meet the highest standards regarding ...

CO2 exhaust unit for can seaming

This CO2 exhaust unit features an integrated washing device connection, Simple disassembly ...

Semi-manual can sealer

When starting out in the canned product business, you do not necessary want to invest in industrial sc...

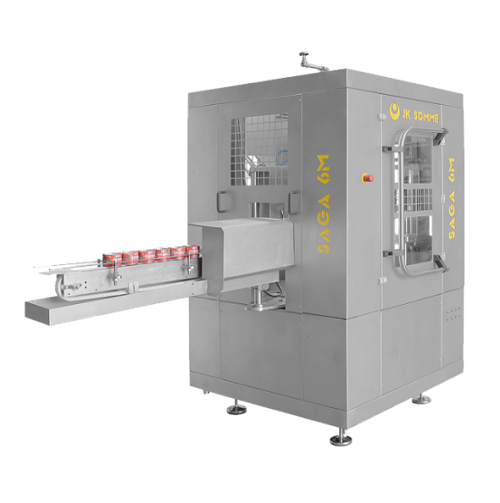

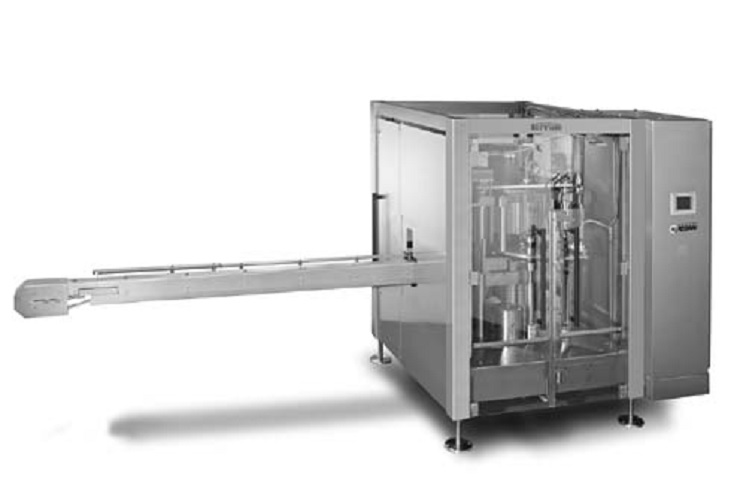

Seaming machine for infant formula cans

Packaging of food products, but especially those for babies, like infant formula, i...

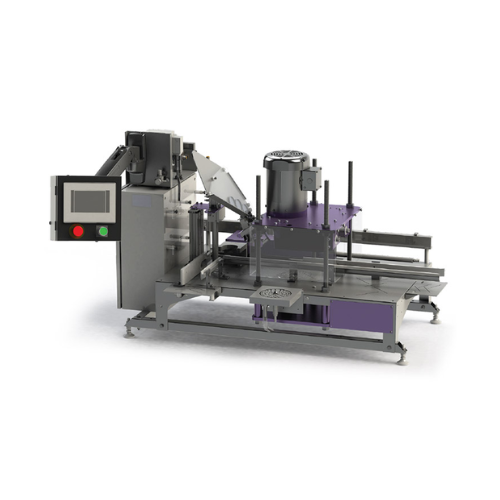

Filling and weight checking machine for food cans

Making sure the right quantity of product is in the packaging can be a ...

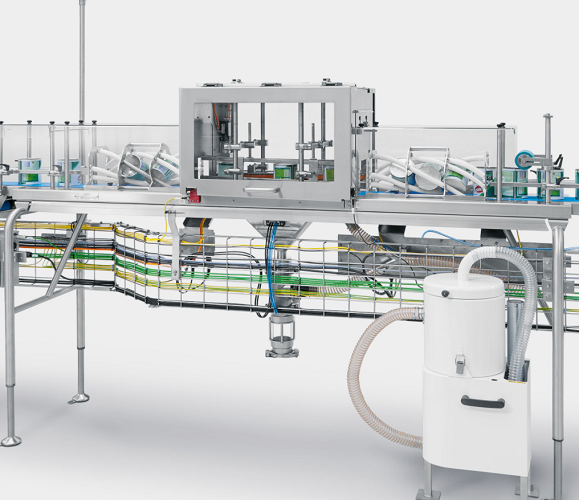

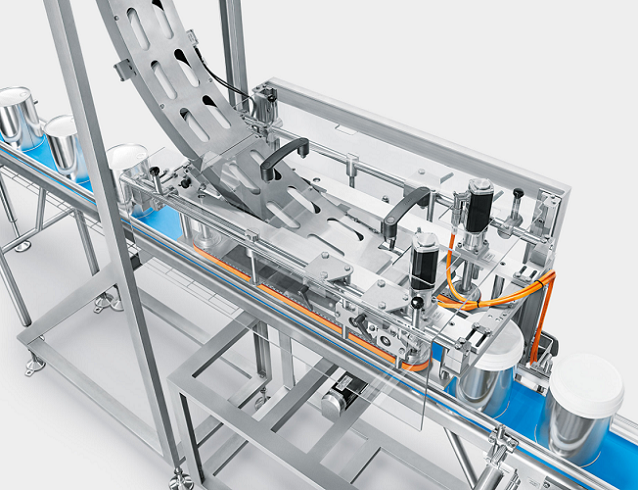

Ionized air system for cleaning of baby food cans

When producing canned food products, especially those for infant...

High speed can seamer

Tin plate thickness for cans has gradually reduced over the years, which makes it a hassle to use new c...

Medium scale round can seamer

Automatic seaming of cans of craft bear can be quite the hassle with the movement from the cen...

Irregular can seamer

Quite some time can be lost adjusting the seaming process to different can sizes when orders keep follow...

Code printer for cans with integrated drying system

Printing date and batch code information on canned consumer items req...

Can filling equipment

Having separate equipment for different process steps like filling and closing, can put a brake on grow...

Can seamer for food products

Flexible can seaming equipment is required to adapt for product-specific variations in food can...

High-speed can seamer for the beverage industry

Fast-moving beverage can filling lines require precise can seaming equipme...

Medium-speed can seamers for the beverage industry

High requirements of the beverage industry mean equipment needs to ada...

Low-speed can seamers for the beverage industry

Adaptable can seaming equipment is required for the more complex multi-fun...

High performance can seamers for the food industry

The wide variation of materials and dimensions used in the food cannin...

Bright beer tanks for breweries

Enhance your beverage production with precise carbonation and conditioning, ensuring excepti...

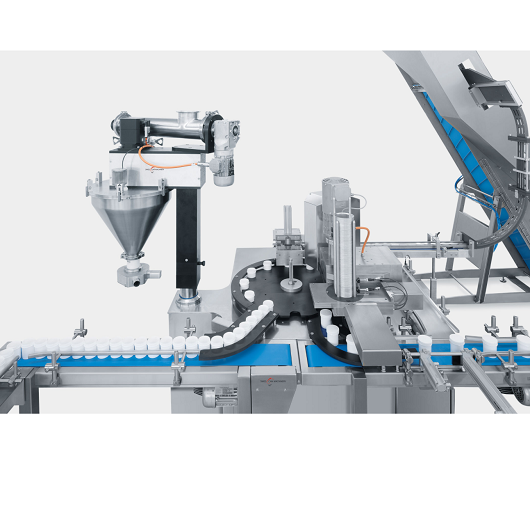

Capping machine for plastic lid oatmeal tins

Some products ask for a plastic reusable lid after the can has been sea...

Multifruit processing line for wholemeal pulps and juices

Optimize your fruit processing capabilities with a skid-based ...