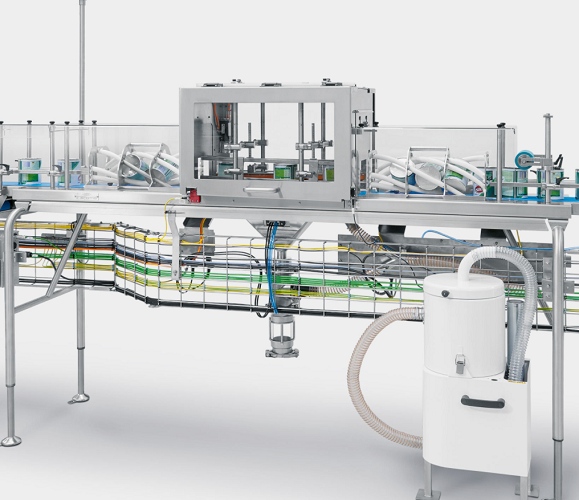

Ionized air system for cleaning of baby food cans

When producing canned food products, especially those for infants, complying to hygiene standards does not on its own exclude contamination with or spoilage through microorganisms or fungus. Before the filling and sealing start, the process line has long begun and so leaves room for spoilage if hygienic measures are not taken to prevent water vapor and moisture.

Cleaning cans with a rotating ion blower nozzle

The Empty Can Cleaning ECC 153 by Swiss Can Machinery is, as the name implies, a machine that cleans cans before they are filled. The machine is mostly designed for canned pharma and (infant) food products. Empty cans are placed upside down on a roster under which is a rotating ion blower nozzle that is connected through a hose with the part of the machine that blows out ionized compressed air.

Clean, compressed air blows out the cans, leaving odourless and residue-free clean air with the help of a 0,01 µ particle filter and an activated carbon filter. This helps in making baby food products as safe as possible.

Benefits

- Stainless steel construction

- Separate compact deduster with filters and dust box

- Optional stainless steel deduster