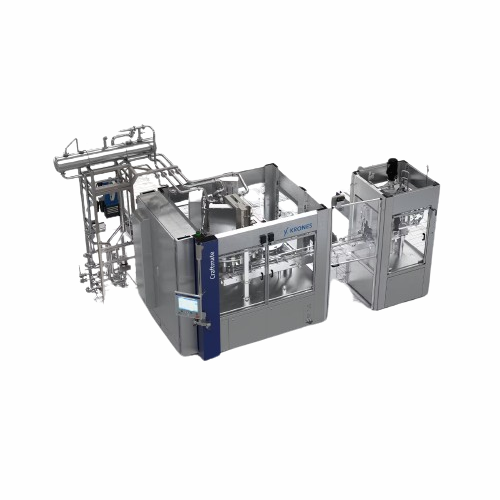

Low output can filler for craft beer

For beverage producers looking to efficiently fill cans with precision, this versatile solution ensures quality and speed with low output flexibility, making it ideal for diverse product ranges like beer, sparkling beverages, and wine—all in a compact design tailored for space-conscious operations.

Fills and Seams Cans Efficiently

The Craftmate C from Krones is a versatile can filler and seaming machine tailored for craft breweries, small beverage producers, and wineries. It stands out for its ability to handle small-scale production efficiently, filling and seaming up to 12,000 cans per hour. The machine’s volumetric filling system uses inductive flow meters to ensure precise fill levels, supporting products ranging from craft beer and carbonated beverages to sparkling wines. Its compact design integrates seamlessly into existing production lines, while offering the flexibility to handle different can sizes and shapes. Designed with an electropneumatically-controlled filling valve system, the Craftmate C minimizes product loss and ensures high filling quality comparable to larger systems. The servo drive system enables smooth operation and integration, while manual insertion of Cleaning-In-Place (CIP) cups ensures easy maintenance. Constructed from stainless steel with an inclined table top, this machine also supports effective cleaning and drainage. The Craftmate C can be configured to meet specific production needs, and its compact form factor reduces transportation costs by fitting into standard sea freight containers.

Benefits

- Increases production efficiency by handling up to 12,000 cans per hour.

- Offers flexibility with the ability to process various can sizes and shapes.

- Minimizes product loss with precision volumetric filling and control systems.

- Reduces installation footprint with its compact, space-saving design.

- Ensures easy maintenance with accessible components and manual CIP capabilities.

- Applications

- Carbonated beverages, Beer, Wine

- End products

- Sparkling wine cans, Craft beer cans, Carbonated soda cans

- Steps before

- Product preparation, Recipe formulation, Ingredient mixing, Pre-cooling

- Steps after

- Seaming, Labeling, Palletizing, Storage and distribution

- Input ingredients

- beer, carbonated soft drinks, wine, co2

- Output ingredients

- filled cans, beer cans, carbonated soft drink cans, wine cans

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Filling speed

- 12, 000 containers per hour

- Can size

- Standard format

- Filling method

- Volumetric filler with inductive flow meter

- Temperature range

- 2 °C to 16 °C

- CO2-content

- 3.8 g/l to 6.0 g/l

- Number of filling valves

- 24

- Diameter

- 1, 080 mm

- Pitch diameter

- 141 mm

- Control system

- Siemens S7 or Allen Bradley

- Drive system

- Servo drive system

- Cylinder type

- Cylinder with Teflon bellows for controlling process gas

- Seamer type

- 4 seaming heads

- Compact design

- Tabletec table top in inclined design for draining of cleaning agents

- CIP cleaning

- Manual insertion of CIP cups

- Working mechanism

- Volumetric filler with inductive flow meter

- Integrated steps

- Filler-capper block synchronisation

- CIP principles

- Closed CIP circuit

- Batch vs. continuous operation

- Continuous operation

- Changeover time

- Short change-over times for different can sizes

- Automation level

- PLC-controlled

- Cleaning method

- CIP / Manual insertion of CIP cups

- Energy efficiency

- Compact and energy-saving design

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Diameter

- 1, 080 mm

- Number of filling valves

- 24

- Can format range

- Standard

- Compact footprint

- Yes, designed for easy transportation

- Inclined table top

- Stainless steel

- Valve manifold

- Manual version with product tank installed on top

- Seamer heads

- 4

- Control panel type

- Touch-screen design

- Control panel type

- Krones operator panel in touch-screen design

- Integration possibilities

- Siemens S7 or Allen Bradley controllers

- Filler-capper block synchronisation

- Servo motor connection of the can seamer