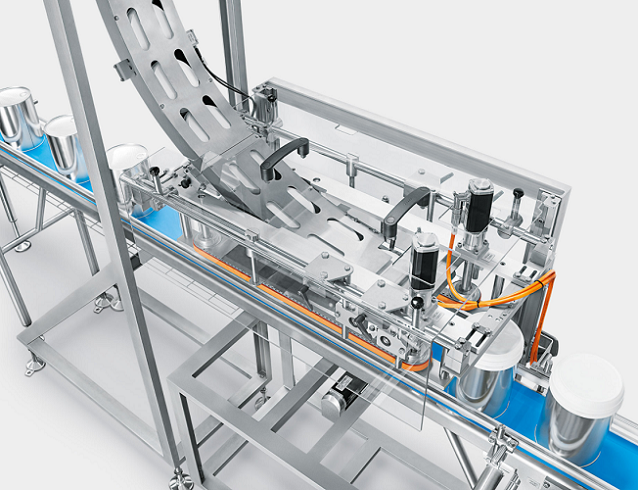

Capping machine for plastic lid oatmeal tins

Some products ask for a plastic reusable lid after the can has been seamed. The closing process might look easy, but often these snap-on lids that need to be on tight, are not placed correctly. And we all know turned caps or caps that fall back to the hopper, will create a jam that you want to prevent.

Putting on snap-on lids from a sloped conveyor

The Capper C 127 by Swiss Can Machinery has a sloped conveyor that puts the lids on the tins from such an angle, that improperly placed lids are an exception. The filled and seamed tins are following a path on a conveyor belt. The lids, coming down from a sloped conveyor are put in place on the tin by two rollers, after which the capped tins follow their way to the end of the belt.

The machine can work with different sizes, as long as the tins have a maximum diameter of 127 mm. The side conveyors have two servo drives and are synchronised with the main conveyor.

Benefits

- Stainless steel belt

- Suited for both tin and plastic snap-on caps

- Automatic discharge of wrongly positioned caps