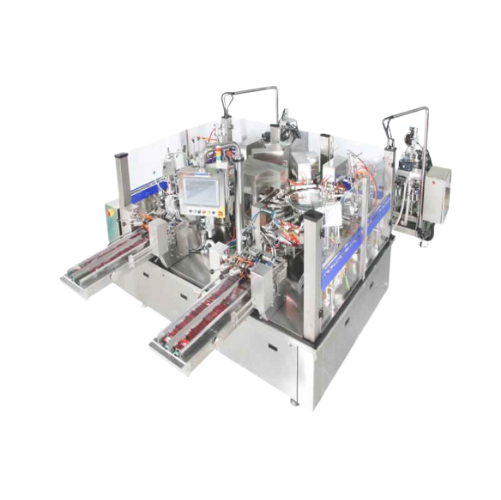

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, perfect for efficiently packaging diverse products from liquids to powders while minimizing space usage and enhancing precision.

Fills and Seals Premade Pouches

The Viking-8SQ-135 from Viking Masek is a compact quadruplex rotary premade pouch machine designed for high-speed, versatile packaging solutions. This machine features dual rotary units with 8 stations each, allowing it to fill and seal four bags simultaneously, achieving speeds up to 200 bags per minute. Ideal for applications across food, beverage, cannabis, and medical industries, it handles a wide range of products including liquids, powders, and solids.

Operating on a robust servo-driven Allen Bradley control platform, the Viking-8SQ-135 offers seamless integration with multi-head scales, volumetric fillers, and auger fillers. The machine’s PLC control with touch screen simplifies operation and allows for storage of production parameters such as gripper size, machine speed, and filling volume. Its two-step sealing process ensures clean seals, bolstered by pouch presence detection and an automatic bag rejection system for quality assurance.

Certified for IP65 or IP66 washdown, this equipment supports rigorous cleaning standards and includes options for gas flushing and dust suction. The customizable design allows for the addition of features like zipper opening devices, date coding, and bag supporters for heavy fills. Compact yet powerful, the Viking-8SQ-135 is engineered to optimize packaging efficiency, making it a valuable asset for any production line looking to enhance throughput without sacrificing space.

Benefits

- Increases production efficiency with speeds up to 200 bags per minute.

- Optimizes floor space with its compact design accommodating four bag fills simultaneously.

- Enhances product quality through a robust sealing process and automatic bag rejection system.

- Supports diverse product types with seamless integration options for various fillers.

- Facilitates maintenance with easy-to-clean, washdown-compliant design.

- Applications

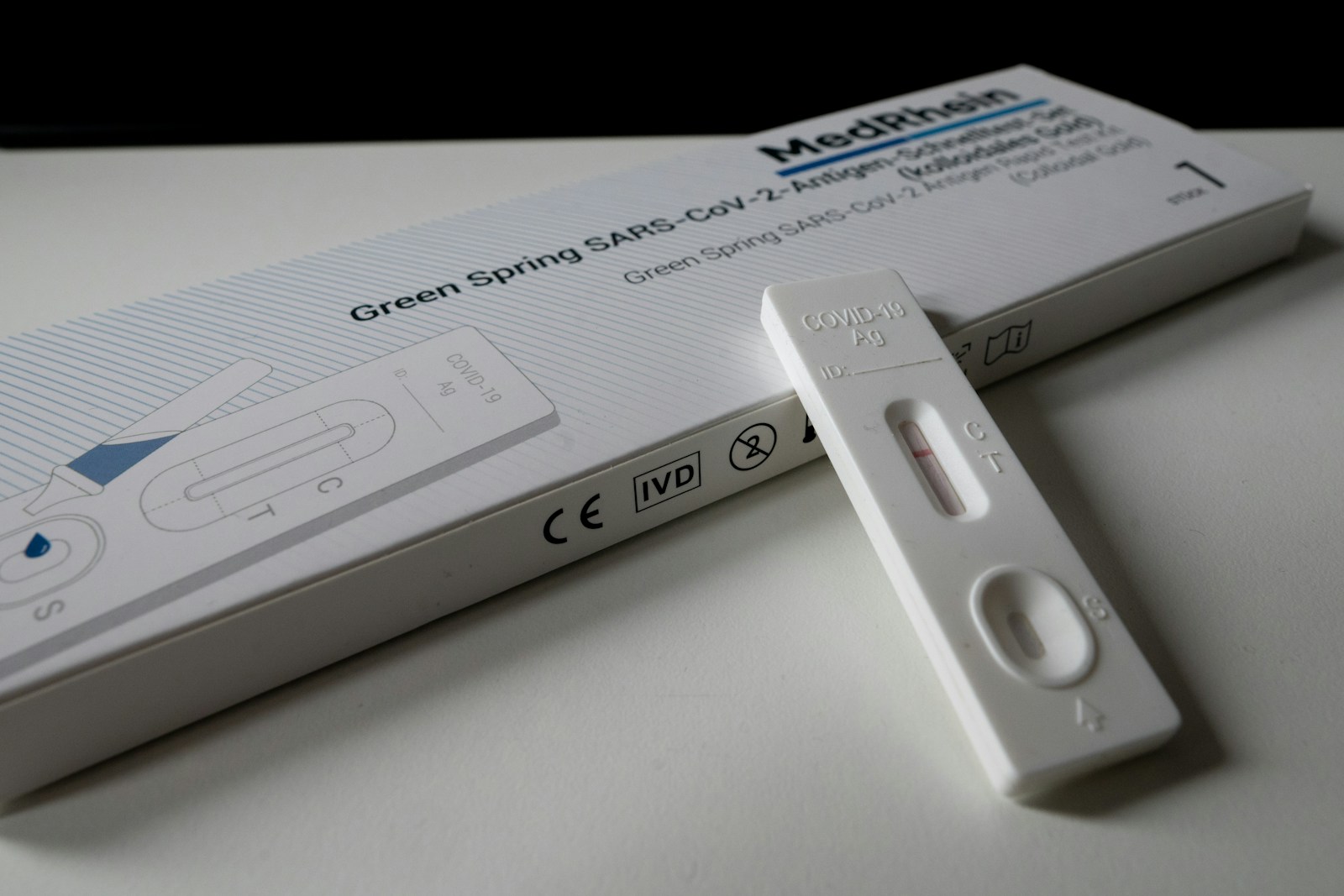

- Treats, Medical devices, Snacks, Bakery, Cheese, Organic foods, Medical testing kits, Fish, Liquids, Food, Fresh fruit, Non-food products, Beans, Supplies, Pills, Cannabis, Capsules, Candy, Pasta, Pet food, Individual quick frozen (iqf), Nuts, Natural, Rice, Health, Cereal, Beverage, Meat, Coffee, Medical, Vegetables, Poultry, Powders

- End products

- Canned beans, Cheddar cheese slices, Dog kibble, Home medical test strips, Fusilli pasta, Organic granola clusters, Candy bars, Basmati rice, Frozen mixed vegetables, Granola bars, Chocolate chip cookies, Orange juice, Chewy candy, Multivitamin tablets, Snack nuts, Roasted coffee beans, Protein powders, Fresh apples, Cornflakes, Syringes, Cleaning wipes, Surgical masks, Cat treats, Cannabis oil, Gel capsules, Vacuum-sealed fish fillets

- Steps before

- Product Filling Preparation, Bag Selection, Deoxidizer Preparation

- Steps after

- Sealing Inspection, Cooling, Quality Control (Checkweigher, Metal Detector, X-ray), Bag Rejection

- Input ingredients

- premade pouches, bags, raw products, liquid products, solid goods, ingredients

- Output ingredients

- filled pouches, sealed bags, packaged products, packaged liquid items, finished goods

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Max Speed

- 200 bpm

- Bag Size (Minimum)

- 90 mm W x 120 mm L

- Bag Size (Maximum)

- 135 mm W x 350 mm L

- Number of Stations

- 8

- Number of Lanes

- 4 (2 duplex rotary units)

- Maximum Speed Per Minute (dry cycle)

- 200

- Bag Gripping Range

- 90-235mm

- Maximum Bag Length

- 350mm

- Electrical Requirements

- 3-Phase, 480V, Approx. 10Kw, 60/50Hz

- Compressed Air

- Approx. 900NL/min, 5~6kgf/cm2

- Control Platform

- Servo-driven Allen Bradley control

- Automation

- PLC control with touch screen operation

- Sealing Process

- Two step sealing process

- Cooling Station

- For liquid products

- Bag Deflation

- With wire guide or push bars

- Working Mechanism

- Dual rotary units

- Integrated Steps

- Fill and seal

- Batch vs. Inline Flow

- Inline Continuous

- CIP Principles

- Clean-in-place design

- Automation Level

- PLC control

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- Yes

- Density/particle size

- Varied

- Abrasion resistance

- Yes

- Product Filling Options

- Powder, liquid, paste

- Control panel type

- PLC control with touch screen operation

- Integration possibilities

- Ethernet connectivity

- Product filling

- Integrated with multi-head scales, volumetric fillers and auger fillers

- Safety features

- Fully interlocked safety guards

- Presealing station

- For liquid or paste

- Gripper size configuration

- Production parameter memory including gripper size