Spray drying solution for heat-sensitive products

Optimize the drying of heat-sensitive and challenging materials into high-quality, agglomerated powders with a system that minimizes waste and enhances productivity.

Transforms Heat-Sensitive Liquids into Agglomerated Powders

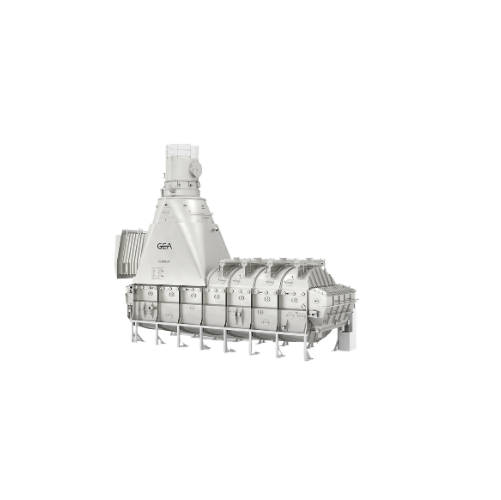

The FILTERMAT® Spray Dryer by GEA is engineered specifically for challenging applications where traditional drying methods fall short, effectively handling heat-sensitive and sticky products. This spray dryer utilizes a perforated filter belt to gently deposit and convey product through controlled drying zones, transforming liquids into agglomerated powders with minimized lumping and deposit formation. Ideal uses include processing whey protein isolate, non-dairy creamers, fruit powders, and more. The design supports continuous operation, with a compact disperser flow straightener and double-feed nozzle system enabling 24/7 production while allowing feedline CIP during operation. Operating at reduced temperatures, it preserves the integrity and quality of sensitive products, while the GEA AddCool heat pump technology significantly lowers energy demand. Available in stainless steel for enhanced corrosion resistance, the FILTERMAT® offers options for retrofitting into existing facilities and testing at GEA’s Soeborg Center of Competence or on-site with pilot plant equipment.

Benefits

- Enhances product quality by gently drying heat-sensitive and sticky materials into uniform agglomerated powders.

- Increases production efficiency with continuous operation and fewer stoppages for cleaning.

- Reduces energy consumption with integrated heat recovery systems.

- Minimizes waste through improved yield and precise control of drying parameters.

- Supports versatile applications, accommodating products from dairy to pharmaceuticals with customizable configurations.

- Applications

- Palatants, Fruit powders, Savory flavors, Hydrolyzed proteins, Fat soluble vitamins, Whey products, Cream powder, Pet food ingredients, Lysed cells, Non-dairy toppings, Cheese powder, High fat non-dairy creamers

- End products

- Whipped cream powder, Non-dairy whipped topping, Vitamin d3 oil, Instant orange juice powder, Yeast extract, Cheddar cheese seasoning, Non-dairy coffee creamer, Fish meal, Hydrolyzed collagen peptides, Whey protein isolate, Chicken flavor enhancer

- Steps before

- Purification, Emulsification

- Steps after

- Packing, Coating

- Input ingredients

- whey permeate, high fat non-dairy creamers, toppings, fruit powders, hydrolyzed proteins, palatants, fat soluble vitamins, lysed cells, fat-filled whey, cream, cheese powder, non-dairy creamers, fruits and vegetables, savory flavors, fish products, meat products, pet food ingredients, emerging food products

- Output ingredients

- free-flowing, agglomerated powders, stable, non-hygroscopic lactose, high-fat content powders, concentrated fruit and vegetable powders, higher fat content flavor products, concentrated biomolecule powders

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Belt speed

- Adjustable

- Retention time

- Variable

- Temperature control

- Multiple zones

- Automation

- PLC-controlled

- Production type

- Continuous / Batch

- Capacity

- Up to 70 kg/h (Pilot scale)

- Cooling method

- Integrated

- Drying zones

- Controlled

- Drying temperature

- Lower than conventional

- Energy saving technology

- GEA AddCool heat pump

- Safety system

- GEA COTECTOR®

- Feed rate

- Variable

- Filtration

- Perforated filter belt

- Working mechanism

- Perforated filter belt drying

- Integrated steps

- Drying and cooling zones

- CIP principles

- Clean-in-place (CIP) system available

- Batch vs. continuous operation

- Continuous operation with FILTERMAT®

- Automation level

- Continuous, 24/7 production

- Energy efficiency

- Recycling and amplifying waste heat with AddCool technology

- Cleanability

- Easy equipment inspection and cleaning

- Density/particle size

- Customized to product requirements

- Biological compatibility

- Suitable for sensitive biomolecules

- Abrasion resistance

- Preserving product structural integrity

- Machine footprint

- Compact

- Belt type

- Perforated filter belt

- Zone configuration

- Controlled dryer zones

- Discharge method

- Free-flowing powder

- Customization

- Retrofit options available

- Belt speed

- Variable

- Dryer type

- Spray dryer

- Controls

- Precise temperature control

- Control panel type

- PLC / HMI

- Belt speed control

- Variable

- Retention time control

- Adjustable

- Temperature zone configuration

- Customizable

- Double-feed nozzle system

- Yes

- Energy-saving options

- GEA AddCool heat pump

- CIP system customization

- Full plant or belt specific

- Safety system inclusion

- GEA COTECTOR®