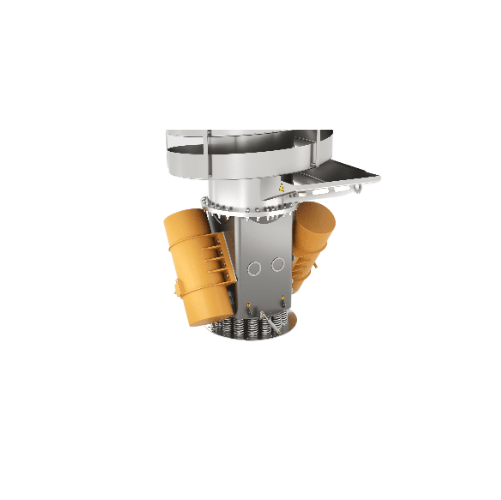

Vibratory spiral elevator for vertical transport

Achieve efficient vertical transport with precise temperature control, suitable for handling diverse product characteristics from frozen to greasy. Designed to integrate seamlessly into your production line, this technology minimizes maintenance interruptions while ensuring gentle handling of sensitive materials, enhancing your operational continuity.

Conveys and Lifts Materials Vertically

The GEA Scan-Vibro Spiral Elevator is a robust vibratory solution tailored for the food, pharmaceutical, and chemical industries. Its unique design conveys materials in a spiral path, offering gentle and effective vertical transport of solids, powders, and granules. This equipment excels in handling dry, wet, warm, greasy, and frozen products, integrating cooling or heating as needed. With spiral diameters ranging from 750 to 1500 mm and lifting heights from 500 to 7000 mm, it addresses diverse operational requirements. Made of stainless steel AISI 304 or 316, it ensures high sanitary standards and corrosion resistance, suitable for continuous operation with negligible maintenance due to its lubrication-free design. The system supports integrated PLC control for seamless production line integration, available with dust covers and customizable support columns to eliminate external frameworks. Meeting current environmental standards, it reduces noise, dust, and odors, making it an eco-friendly choice for processing applications such as conveying, lifting, and simultaneous material treatment.

Benefits

- Enhances product integrity with gentle handling, minimizing damage and degradation.

- Reduces maintenance costs through a lubrication-free design.

- Adapts to varying production needs with customizable configurations.

- Integrates seamlessly into existing systems with PLC control options.

- Contributes to environmental sustainability by minimizing noise, dust, and odors.

- Applications

- Food, Chemicals, Feed, Agglomerates, Snacks, Granules, Warm products, Instantized products, Wet products, Powder, Greasy products, Frozen products, Dairy, Pharmaceuticals

- End products

- Instant oatmeal, Frozen vegetable packs, Potato chips, Pharmaceutical capsules, Cosmetic powders, Heated beverages, Dairy creamer powders, Grease cooked chips, Pet food pellets, Powdered drink mixes, Instant soups, Instant coffee, Protein powders, Cornflakes, Granola, Tablet coating powders, Muesli base flakes, Frozen fruit packs, Chemical granules, Snack pellets

- Steps before

- Mixing, Forming, Blending

- Steps after

- Cooling, Heating, Packing

- Input ingredients

- dry materials, wet materials, warm materials, greasy materials, frozen materials

- Output ingredients

- conveyed products, heated products, cooled products, spread products, unified products

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Spiral diameter

- 750 to 1500 mm

- Lifting height

- 500 to 7000 mm

- Vertical transport direction

- Upward or downward

- Material construction

- Stainless steel, AISI 304 or 316

- Cooling/heating system

- Available on request

- Dust covering

- Available on request

- Motor positioning

- Top or bottom

- Continuous operation design

- Yes

- Working mechanism

- Spiral conveying with oscillation

- Integrated steps

- Cooling, heating, spreading, unification

- Batch vs. continuous operation

- Continuous

- Cleaning method

- High-sanitary design

- Maintenance requirements

- Negligible maintenance

- Noise,dust,and odor reduction

- Integrated

- Energy Efficiency

- Designed for continuous operation

- Material handling capability

- Dry, wet, warm, greasy, frozen products

- Automation level

- Not explicitly mentioned

- Cleanability

- High-sanitary and easy-to-clean design

- Abrasion resistance

- Very gentle handling due to oscillation and vibration frequency

- Corrosive resistance

- Available in stainless steel AISI 304 or 316

- Biological compatibility

- Suitable for food, feed, and pharmaceutical industries

- Density/particle size

- Handles various product characteristics (dry, wet, warm, greasy, frozen)

- Spiral diameter

- 750 to 1500 mm

- Lifting height

- 500 to 7000 mm

- Material

- Stainless steel, AISI 304 or 316

- Control panel location

- Top or bottom

- Spiral diameter

- 750 to 1500 mm

- Lifting height

- 500 to 7000 mm

- Material of construction

- Stainless steel, AISI 304 or 316

- Cooling or heating system

- On request

- Dust covering

- On request

- Motor position

- Top or Bottom

- Support column integration

- Integrated

- Sanitary design

- Standard or tailor-made