Super high shear inline disperser for nanoparticle production

Achieve unmatched particle size reduction with cutting-edge shear processing, enabling the production of nanoemulsions and nanoparticles crucial for high-precision formulations in pharmaceuticals and cosmetics.

Processes Nanoemulsions and Nanoparticles Efficiently

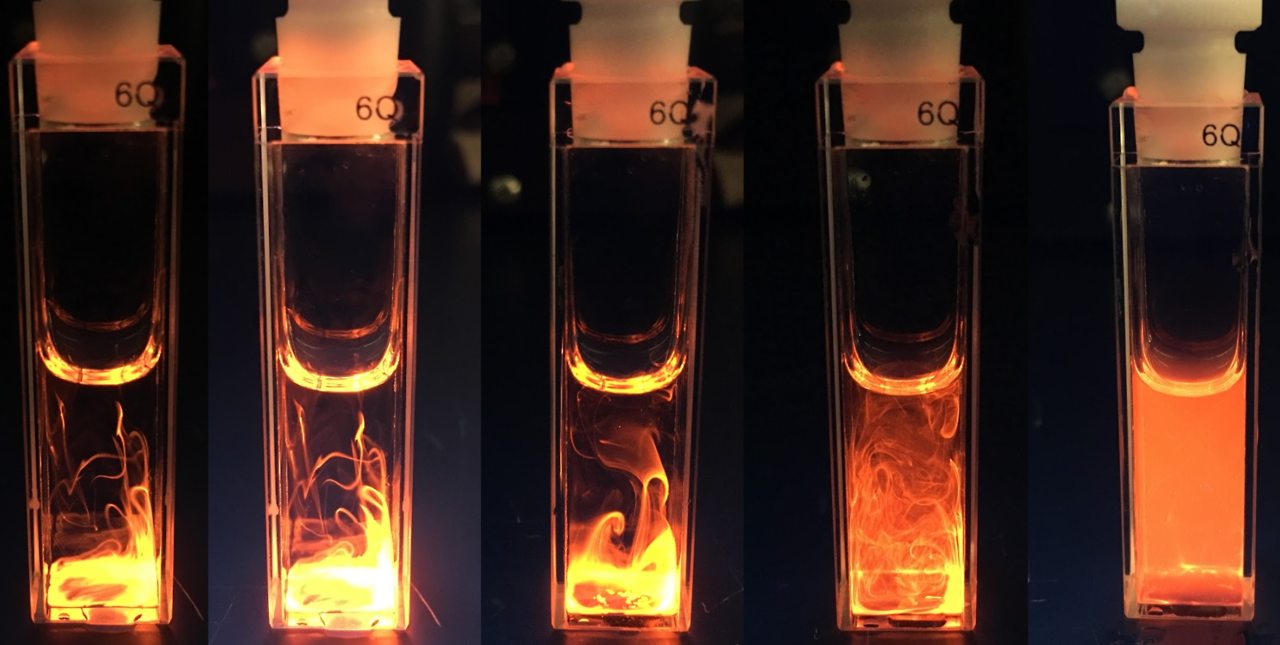

The MEGATRON® MT-SHS from Kinematica AG is a state-of-the-art high shear in-line disperser designed for demanding applications in pharmaceuticals, cosmetics, and food processing. This equipment features advanced rotor-stator technology capable of delivering rotor tip speeds of up to 65 m/s and a shear rate of 300,000 s-1, making it ideal for processing nanoemulsions and nanoparticles. It accommodates a variety of end-products, from APIs and liposomes to cosmetic serums and beverage emulsions. Featuring a powerful 5.5 kW motor with stepless speed control, the MT-SHS ensures precise and consistent operation. Its stainless steel construction provides excellent corrosion resistance and compatibility with a wide range of materials, while the double-walled recirculation vessel allows for efficient thermal management. The machine supports continuous, high-speed operations and can be integrated seamlessly into existing production lines, offering scalability from lab to production environments. With customizable rotor-stator geometries and integrated process controls, the MT-SHS ensures optimal performance and adaptability for specific production requirements, conforming to industry standards for safe and efficient operation.

Benefits

- Achieves nano-sized particles, enhancing product stability and performance.

- Increases production efficiency with high shear rates and tip speeds.

- Facilitates seamless scale-up from laboratory to industrial production.

- Minimizes waste and energy use with optimized processing controls.

- Adapts to various applications with customizable rotor-stator geometries.

- Applications

- Food, Nanoparticles, Nanoemulsions, Cosmetics, Chemical, Life science, Pharmaceuticals

- End products

- Paints and coatings, Encapsulated flavors, Active pharmaceutical ingredients (apis), Nanocapsules, Protein shakes, Polymer solutions, Beverage emulsions, Chemical suspensions, Cosmetic serums, Nanoemulsified essential oils, Liposomes for drug delivery, Cream emulsions

- Steps before

- Emulsification, Grinding

- Steps after

- Nano milling, Packing

- Input ingredients

- continuous phase input, raw materials, component system

- Output ingredients

- nano sized particles, nano sized droplets, processed materials

- Market info

- Motor Power

- 5.5 kW

- Speed Adjustment

- Stepless with integrated controller and digital display

- Rotational Speed

- up to 25, 000 rpm

- Shear Rate

- up to 300, 000 s-1

- Recirculation Vessel Capacity

- 5.0 liter

- Tip Speed

- max approx. 65 m/s

- Pipe Installation

- Complete piping with the recirculation vessel

- Dimensions

- 715 x 300 x 1020 mm

- Working mechanism

- Rotor/Stator Technology

- Flow type

- In-line

- Particle size reduction capability

- Nano-sized particles

- Speed control

- Stepless with Integrated Controller

- Energy input

- High Specific Energy Input

- Shear rate

- Up to 300, 000 s-1

- Automation level

- Digital Display with Speed Adjustment

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- High

- Density/particle size

- 0.5–2.5 g/cm³ / Nano range

- Machine footprint

- 715 x 300 x 1020 mm

- Pipe installation

- Complete piping with recirculation vessel

- Recirculation vessel capacity

- 5.0 liter

- Vessel design

- Double-walled with thermostat connections

- Rotor/Stator geometries

- Different geometries available

- Recirculation vessel

- 5.0 liter stainless steel, double-walled design with thermostat connections

- Pipe installation

- Complete piping with the recirculation vessel