Vertical form fill seal packaging system

Enhance your packaging line with precision sealing and efficient throughput, ideal for high-speed operations across diverse product forms.

Forms, Fills, Seals, and Cuts Packaging

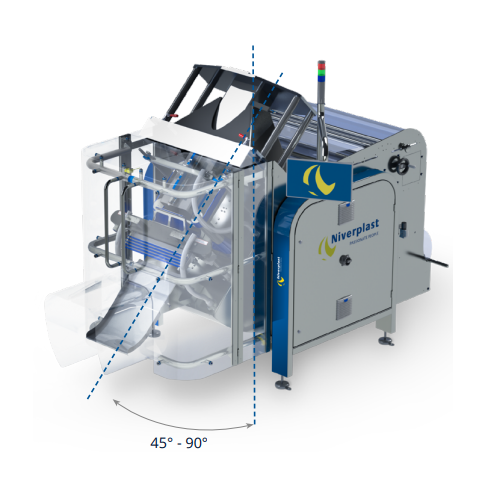

The SEPP machine from Niverplast B.V. is a versatile vertical form fill seal solution designed to streamline the packaging process across a range of industries including bakery, meat, and e-commerce. Distinguished by its compact design, the SEPP operates with an intuitive touchscreen interface, configured in multiple languages, ensuring ease of use in fast-paced environments. Capable of packaging up to 1,800 bags per hour, this machine accommodates a wide variety of film roll sizes to suit different packaging needs.

Niverplast’s SEPP can be configured in a vertical or 45° inclined filling position, providing flexibility to match production line requirements. Its fully stainless-steel construction and low-maintenance design offer robust performance, while integrated film alignment maintains precise packaging consistency. With impulse sealing and a film cutting blade, the SEPP supports continuous operation, minimizing downtime and maximizing efficiency. Optional modules, such as a thermotransfer print and gusseted bag capability, further enhance its functionality. Perfect for processing solid and powdered products, SEPP seamlessly integrates into existing packaging lines, improving throughput and operational efficiency while maintaining product integrity.

Benefits

- Enhances production efficiency with throughput of up to 1,800 bags per hour.

- Reduces manual adjustment time with easy-to-use, intuitive touch-screen controls.

- Optimizes space with a compact design and small floor footprint.

- Supports diverse packaging needs with flexible film size accommodation and filling positions.

- Minimizes maintenance costs due to its reliable, low-maintenance construction.

- Applications

- E-commerce, Bakery, Meat, Fats, Oils, Fruits, Laundry, Powder, Vegetables, Moulding, Others, Fish

- End products

- Bread rolls, Olive oil, Protein powders, E-commerce parcels, Fresh fruit mixes, Pre-cut vegetables, Sliced bread, Laundry bags, Croissants, Margarine, Sausages, Spice mixes, Fish fillets, Plastic moulded parts, Detergent pods

- Steps before

- Product preparation, Film roll clamping, Film alignment

- Steps after

- Distribution, Sealing integrity check, Storage

- Input ingredients

- film roll, products

- Output ingredients

- airtight packaging, portioned packaging, bags

- Market info

- Niverplast is known for innovative packaging solutions, specializing in industrial engineered-to-order equipment for bag-in-box systems, tray handling, and carton erecting machinery, with a strong reputation for quality and reliability in the packaging industry.

- Bagging speed

- Up to 1800 bags per hour

- Automation

- Interactive, intuitive operating software

- Design

- Compact design with a small floor print

- Material

- Stainless steel design

- Maintenance

- Easy access for maintenance and cleaning

- Film sealing

- Impulse seal with film cutting blade

- Film alignment

- Integrated film alignment (operated on the touchscreen)

- Control Interface

- Easy-to-operate touch IPC

- Language Support

- Available in a language of your choice

- Filling position

- Vertical or 45° inclined

- Working mechanism

- Vertical form-fill-seal

- Incline flexibility

- Vertical or 45° inclined

- Automation level

- Interactive touchscreen

- Changeover time

- Very easy to adjust and operate

- Batch vs. continuous operation

- Continuous

- CIP/SIP

- Easy access for maintenance and cleaning

- Cleaning method

- Easy access for maintenance and cleaning

- Film alignment

- Integrated, operated on touchscreen

- Cleanability

- Easy access for maintenance and cleaning

- Corrosion resistance

- Stainless steel design

- Compact footprint

- Small floor print

- Filling Position

- Vertical / 45° inclined

- Discharge method

- Vertical form fill seal

- Control panel type

- Interactive touchscreen

- Materials Used

- Stainless steel

- Sealing method

- Impulse seal with cutting blade

- Control panel type

- Interactive touchscreen