Vertical batch centrifuge for solid-liquid separation

Optimize your solid-liquid separation process with high-speed centrifuging, ensuring precise filtration and decanting, essential for maintaining product integrity and enhancing throughput efficiency.

Processes Slurries and Enhances Solid-Liquid Separation

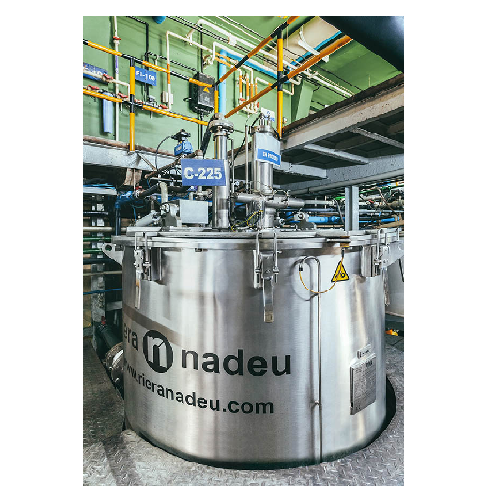

The RINA 300 from Riera Nadeu is a robust vertical batch centrifuge designed for effective solid-liquid separation in demanding industrial environments. Featuring an automatic discharge mechanism, this bottom discharge peeler centrifuge offers both filtering and decanting options to suit varying slurry characteristics. It’s ideal for applications such as pharmaceutical API crystallization, lithium carbonate processing, and food ingredient refinement, handling a range of end-products from protein isolates to glycol ethers. Capable of processing substantial slurry volumes, its versatility allows for multiple configurations, including variable residence time, intensive washing phases, and automatic control. Constructed in materials ranging from basic steel to high-grade alloys, it ensures chemical compatibility and durability in harsh conditions. Its design supports easy cleaning and maintenance with CIP systems, making it compliant with industry standards. For facilities operating in hazardous areas, the RINA 300 can be adapted to meet explosion-proof certifications.

Benefits

- Enhances product purity and consistency with efficient solid-liquid separation.

- Minimizes labor intervention with automatic discharge and PLC-controlled operation.

- Reduces energy usage through optimized variable-speed control.

- Adapts to various process needs with configurable filtering and decanting options.

- Ensures compliance and safety in hazardous environments with explosion-proof designs.

- Applications

- Chemicals, Food, Gas, Meg reclaiming, Fine chemicals, Oil, Base chemicals, Biotech, Foodstuff, Mining, Pharmaceuticals

- End products

- Mineral oils, Active pharmaceutical ingredients, Lithium carbonate, Monoclonal antibodies, Xanthan gum, Polyethylene glycols, Protein isolates, Caffeine, Glycol ethers, Sodium bicarbonate, Citric acid, Aroma compounds, Omega-3 fish oil

- Steps before

- Slurry preparation, Emulsification, Blending

- Steps after

- Drying, Washing, Clarification, Solid handling, Packaging

- Input ingredients

- slurries, solids, liquids, suspensions

- Output ingredients

- separated solids, clarified liquid, permeable cake, overflown liquid

- Market info

- Riera Nadeu is known for its expertise in manufacturing centrifuges and drying equipment, particularly for industrial applications. They are reputed for high-quality, customized, engineered-to-order solutions in separation technologies for various industries.

- Automation

- Automatic discharge

- Capacity

- 55 to 1300 dm³

- Filtering Area

- 0.66–5.65 m²

- Speed

- 1000–2350 rpm

- G Factor

- 1000–2000 G

- Cake Weight Capacity

- 690–1460 kg

- Basket Diameter

- 650–1800 mm

- Cake Thickness

- 97–270 mm

- Dimensions (W x L x H)

- 1100x1600x1200 mm to 2350x3560x3400 mm

- Working mechanism

- Vertical batch, automatic discharge

- Automation level

- Automatic discharge

- CIP/SIP

- CIP available

- Batch vs. continuous operation

- Batch

- Energy efficiency

- N/A

- Cleaning method

- Automatic scraping and discharge

- Changeover time

- N/A

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- 1100x1600x1200 mm to 2350x3560x3400 mm

- Basket Diameter

- 650 mm to 1800 mm

- Basket Height

- 325 mm to 1000 mm

- Cake Volume Capacity

- 55 to 1300 dm3

- Cake Thickness Max

- 97.5 mm to 270 mm

- Discharge Method

- Automatic bottom discharge

- Basket Type

- Filtering (F) or Decanting (D)

- Filtration basket type

- Filtering (F) / Decanting (D)

- Material type

- Basic steel / High-grade alloy

- Safety certification

- Explosive hazardous area certification

- Control features

- Automatic discharge / Variable residence time control

- Maintenance features

- Easy-maintenance design

- Configuration options

- Blanketing, spinning, washing(s), CIP