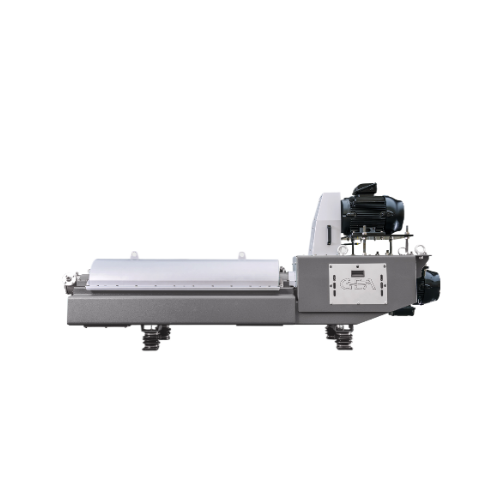

Clarifying decanter for food ingredient processing

Optimize your protein recovery and ensure high-quality separation with advanced clarifying decanters, designed for efficient processing of plant proteins and amino acids in continuous production lines.

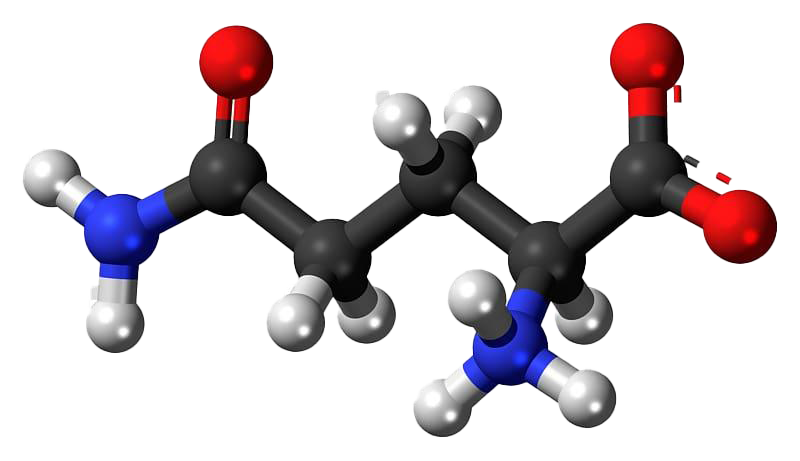

Processes and Clarifies Plant-Based Proteins and Algae

The clarifying decanter centrifuge from GEA is engineered for high-efficiency protein recovery across multiple applications. Utilizing a robust summationdrive system, it operates at high differential speeds without requiring pulley changes, ensuring continuous and adaptable separation processes. Ideal for the concentration of soy, rice, and pea proteins, this centrifuge enhances the production of tofu, textured vegetable proteins, and algal supplements. It accommodates rigorous plant-based protein separation, handling both solid and slurry forms efficiently.

Capable of integrating seamlessly within existing production lines, the centrifuge supports continuous automated operation and offers adjustable pond depths via the patented GEA varipond® weir system, optimizing dewatering and minimizing energy consumption. Constructed with hygienic design principles, it adheres to stringent food safety standards, while its external gear segregation and separate lubrication ensure extended durability and minimal contamination risk.

Available with stainless steel options for enhanced corrosion resistance, the equipment supports CIP (Clean-In-Place) systems for efficient maintenance. This flexibility, combined with customization services from GEA’s engineering support team, allows adaptation to specific throughput requirements, ensuring compliance with industry regulations.

Benefits

- Enhances protein yield and purity with high-speed separation.

- Adapts to process changes seamlessly with variable pond depth control.

- Minimizes operational costs through energy-efficient motor technology.

- Ensures food safety with hygienic and contamination-resistant design.

- Simplifies maintenance with integrated lubrication and CIP systems.

- Applications

- Amino acids, Vegetable proteins, Protein recovery, Meat alternatives, Snack bars, Algae concentration, Food ingredients, Rice proteins, Plant proteins, Pea proteins, Soy proteins

- End products

- Algal supplements, Protein powders, Algal biomass, Lysine supplements, Textured vegetable protein (tvp), Protein-enriched energy bars, Plant-based milk alternatives, Protein isolates, Plant-based meat products, Protein-enhanced sports drinks, Tofu

- Steps before

- Grinding, Emulsification

- Steps after

- Drying, Packing

- Input ingredients

- soy, rice, pea, vegetable proteins, algae, amino acids, lysine

- Output ingredients

- plant proteins, protein recovery, concentration, dewatering

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Differential Speed Range

- Adjustable without pulley change

- Torque

- Full torque at all times

- Power Flow

- Optimized with GEA summationdrive

- Pond Depth Adjustment

- Automatic with GEA varipond®

- Hygienic Design

- Meets all food requirements

- Dewatering Efficiency

- Optimum pond depth for low energy consumption

- Operation

- Hydrohermetic with paring disk

- Protein Loss Prevention

- Minimized

- Working mechanism

- Decanter centrifuge

- Integrated steps

- Protein recovery and concentration

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP

- Energy efficiency

- Low energy consumption

- Adjustable pond depth

- GEA varipond® system

- Paring disk operation

- Hydrohermetic

- Differential speed range

- High, without pulley change

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank shape

- Cylindrical

- Feed/discharge method

- Centrifugal

- External gears

- Yes

- Hygienic design

- Yes

- Control panel type

- Digital

- Adjusting weir

- GEA varipond®

- Hydrohermetic operation

- Paring disk

- Pond depth adjustment

- Adjustable during operation

- Drive system

- GEA summationdrive with optimized power flow

- Weir adjustment

- Patented adjusting weir – GEA varipond®