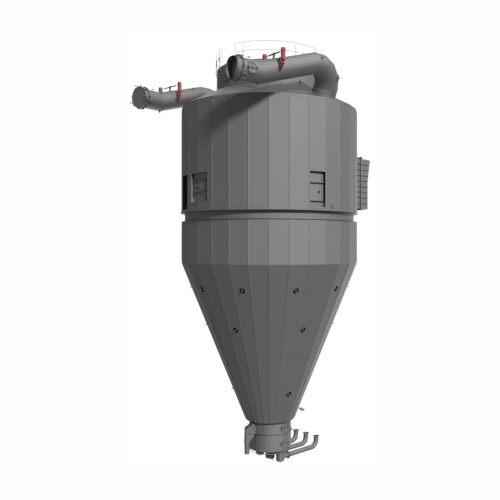

Wide body dryer for dairy and food products

Achieve precise moisture control and optimal powder agglomeration for dairy and food products, ensuring your production line delivers consistent and high-quality output with reduced bulk densities and enhanced mixing capabilities.

Processes and Dries Powders and Granules Efficiently

The Wide Body Dryer from RELCO® provides a robust solution for industrial powder processing across diverse sectors such as food, dairy, and pharmaceuticals. This equipment features a vertical hot air distributor, ensuring even drying with minimal fan pressure, while its vibrating plug flow bed aids in precise moisture control. Ideal for applications ranging from non-fat dry milk to pharmaceutical-grade lactose, it supports continuous, customizable operations for various solid and granule product types. Equipped with advanced features like a Fines Return System and directional fluidbed screens, it enhances product quality through natural agglomeration. With options for a multi-fuel indirect heater and efficient heat recovery, it maximizes energy efficiency. The inclusion of a baghouse emissions system and retractable CIP nozzles facilitates easy maintenance and compliance with industry standards. Fully customizable to fit your production needs, the Wide Body Dryer integrates seamlessly into your processing line, backed by engineering support to fine-tune its capabilities.

Benefits

- Enhances product consistency with precise moisture control and natural agglomeration.

- Increases energy efficiency through optimized airflow and heat recovery systems.

- Minimizes maintenance downtime with an integrated baghouse emissions system and CIP capabilities.

- Customizable design adapts to a wide range of production requirements and materials.

- Supports continuous operation, boosting overall production line efficiency.

- Applications

- Beverages, Protein powders, Sweetened condensed milk, Nutritional supplements, Pet food, Yeasts, Bakery ingredients, Cheese, Food ingredients, Infant milk formulas, Pharmaceutical powders, Dairy products, Encapsulated powders

- End products

- Baking mixes, Milk protein concentrate (mpc), Infant formula, Egg white protein powder, Whey protein isolate (wpi), Pharmaceutical grade lactose, Encapsulated oil powders, Microparticulated whey protein concentrate, Whey protein concentrate (wpc), Whole milk powder (wmp), Pet nutrition formulas, Fruit juice powders, Buttermilk powder, Cheese powder, Cream powder, Milk protein isolate (mpi), Non-fat dry milk (nfdm), Codex skim milk, Yeast extract, Vitamin and mineral powders

- Steps before

- Liquid Concentration, Mixing, Homogenization

- Steps after

- Agglomeration, Lecithination, Packing

- Input ingredients

- NFDM, Codex Skim, WMP, WPC34-80, WPI, Buttermilk, MPC80, MPI, IMF, Microparticulated WPC, Pro-cream, Yeasts, Encapsulated Powders, Blood

- Output ingredients

- Dried NFDM, Dried Codex Skim, Dried WMP, Dried WPC34-80, Dried WPI, Dried Buttermilk, Dried MPC80, Dried MPI, Dried IMF, Dried Microparticulated WPC, Dried Pro-cream, Dried Yeasts, Dried Encapsulated Powders, Dried Blood

- Market info

- Kovalus Separation is known for manufacturing industrial engineered-to-order (ETO) separation equipment, specializing in tailored solutions for complex filtration and separation needs, with a strong reputation for innovation, quality, and reliability in various industries.

- Dryer Type

- Wide Body Dryer

- Material Compatibility

- NFDM, Codex Skim, WMP, WPC34-80, WPI, Buttermilk, MPC80, MPI, IMF, Microparticulated WPC, Pro-cream, Yeasts, Encapsulated Powders, Blood

- Air Distribution System

- Vertical Air Distributor

- Workflow

- Vibrating well mixed and plug flow beds

- Exhaust System

- Top chamber exhaust ports

- Fines Return System

- Nozzles, front of fluidbed, end of fluidbed

- Lecithination

- Optional

- Agglomeration

- Natural induced agglomeration

- Heat Recovery

- Included

- Baghouse Emissions System

- Identifies leaking bag row

- Automation

- PLC-controlled

- Feed System

- Dual feed system

- CIP Nozzles

- Retractable

- Spray Nozzle Cameras

- Included

- Fuel Type

- Multi fuel indirect fired heater

- Working mechanism

- Vertical hot air distributor with vibrating well mixed and plug flow beds

- Integrated steps

- Multi fuel indirect fired heater, Cyclones, Heat recovery

- CIP principles

- Retractable CIP nozzles

- Batch vs. inline flow

- Continuous operation

- Automation level

- SepTrac™ Smart System

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- Customizable

- Tank Shape

- Wide Body

- Feed/Discharge Method

- Dual Feed System

- Air Distribution

- Vertical Air Distributor

- Bed Type

- Vibrating Well Mixed and Plug Flow Beds

- Baghouse

- Included

- Indirect Fired Heater

- Multi fuel

- Cyclones

- Yes

- Baghouse Fines Retention Bin

- Yes

- Heat Recovery

- Yes

- Dual Feed System

- Yes

- Retractable CIP Nozzles

- Yes

- Lecithination

- Yes

- Spray Nozzle Cameras

- Yes