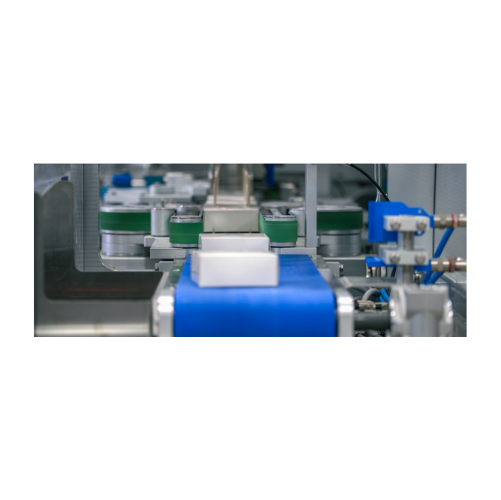

Cartoning solution for pharmaceutical products

Ensure accurate and efficient packaging of pharmaceutical products with precision cartoning, designed for seamless integration into your automated production line, maintaining product integrity and compliance with industry standards.

Stacks and Loads Cartons with Precision

Universal Pack’s Cartoning Machines are designed to meet the stringent demands of pharmaceutical and nutraceutical manufacturers, offering both intermittent and continuous high-speed operations. These machines specialize in integrating stacking, insertion, loading, weighing, and labeling processes to ensure precise cartoning of powders, granules, liquids, and tablets. Built with robustness in mind, they feature a compact footprint and provide flexibility in carton formats with easy access for quick changeovers. The machines are compatible with both pre-glued and flat blank cartons, leveraging top and side loading systems to increase operational efficiency. Equipped with an End of Line (EOL) and Track & Trace (T&T) module, they ensure compliance with serialization and aggregation standards, crucial for industry regulations. Available in stainless steel for enhanced durability, these machines support full automation and seamless integration with primary packaging machines. Designed to meet GMP standards, they offer customizable engineering support to accommodate specific production needs.

Benefits

- Enhances operational efficiency with seamless integration into existing production lines.

- Minimizes labor expenses through automated size changeover and access features.

- Ensures regulatory compliance with GMP standards and robust serialization.

- Increases packaging flexibility for varied carton configurations and product types.

- Reduces production delays with reliable continuous and intermittent operational modes.

- Applications

- Cosmetic powders, Chemical granules, Pharmaceutical liquids, Nutraceutical powders, Cosmetic liquids, Pharmaceutical tablets, Nutraceutical granules, Nutraceutical liquids, Chemical powders, Pharmaceutical viscous products, Chemical tablets, Cosmetic granules, Nutraceutical tablets, Pharmaceutical powders, Pharmaceutical granules

- End products

- Detergent powder, Herbal extract liquid, Effervescent granules, Vitamin c tablets, Cough syrup, Facial scrub granules, Moisturizer, Protein powder, Multivitamin tablets, Chlorine tablets, Hydrocortisone cream, Omega-3 capsules, Dishwasher granules, Paracetamol powder, Eyeshadow powder

- Steps before

- Purification, Granulation, Mixing, Counting, Stacking

- Steps after

- Labeling, Weighing, Serialization, Aggregation, Tamper Evident Labeling

- Input ingredients

- stacked sachets, stick packs, pre-glued cartons, flat blank cartons

- Output ingredients

- filled cartons, sealed cartons

- Market info

- Universal Pack is known for designing and manufacturing high-quality, customized packaging machines, specializing in sachet and stick pack technology for various industries, renowned for reliability, innovation, and exceptional customer support.

- Motion System

- Intermittent, Continuous

- Carton Type

- Pre-glued or Flat Blank

- Loading System

- Top Loading / Side Loading

- Integration Capability

- Fully-Automatic with Primary Packaging

- Flexibility in Cartons’ Formats

- Total Flexibility

- Changeover Time

- Fast

- Throughput

- High

- Footprint

- Robust and Compact

- Construction

- Built In-House

- Compliance

- Pharmaceutical Industry Standards

- End of Line Module

- With Track, Trace

- Weighing Capability

- Included in EOL Module

- Vision System

- Included in EOL Module

- Serialization and Aggregation

- Included in Line

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Intermittent, Continuous Motion

- Changeover time

- Fast parts and size changeovers

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container Type

- Pre-glued and Flat Blank Cartons

- Pharmaceutical Suitability

- Meets Stringent Pharmaceutical Needs

- Machine Footprint

- Compact

- Carton Type

- Pre-glued / Flat Blank

- Access

- Double Balcony

- Loading System

- Top Loading / Side Loading

- Carton formats flexibility

- Various sizes

- Integration with primary packaging

- Stick packs and sachets integration

- Access for operators

- Double balcony design

- Packaging type compatibility

- Pre-glued and flat blank cartons

- Machine type

- Standard/Custom

- Motion type

- Intermittent, Continuous

- Loading system

- Top and side loading

- Customization for package insertion

- Counting and stacking unit

- Weight and tracking integration

- EOL and T, T module

- Production line integration

- Fully-automatic line capability

- Carton closing system

- Gluing and closing unit

- Serialization,aggregation

- Integral component