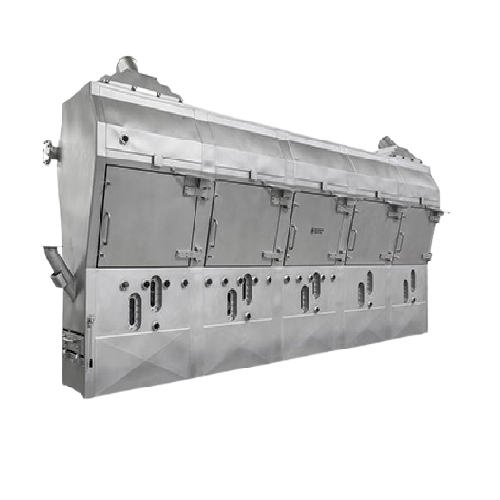

Continuous wet granulation equipment

Optimize your production line with continuous wet granulation, seamlessly transforming powders into uniform granules for efficient downstream processing in tablet and capsule production.

Processes Continuous Wet Granulation for Consistent Output

The Continuous Wet Granulation Equipment from NEUHAUS NEOTEC, a subsidiary of Germany’s KAHL group, delivers efficiency and precision for pharmaceutical and health food production. This system excels in integrating processes such as feeding, mixing, granulating, drying, tableting, and coating into a seamless continuous operation. Its pilot scale capacity begins at 20kg/h, scaling up to commercial outputs exceeding 2000kg/h. Designed for producing effervescent tablets, multivitamins, dietary supplements, and more, it features a horizontal fluid bed processor for top-spray granulating and bottom-spray pellet coating. The equipment incorporates PAT technology for real-time process data monitoring and feedback, ensuring compliance with EMA and FDA data integrity requirements. Boasting ATEX explosion-proof certification, it is constructed for robust safety and material compatibility. Additionally, it offers a customized flexible solution to accommodate multiple products on a single line, supporting diverse production needs with engineering support tailored to your specifications.

Benefits

- Enhances product consistency with integrated continuous processing.

- Streamlines production scale-up from pilot to commercial, reducing development time.

- Increases operational safety and compliance with ATEX and FDA standards.

- Optimizes resource use with real-time process monitoring and feedback.

- Customizable to handle diverse product lines, enhancing production flexibility.

- Applications

- Active pharmaceutical ingredients (api), Health foods, Oral solid dosage (osd) products, Pharmaceuticals

- End products

- Herbal extract granules, Probiotic capsules, Antihypertensive tablets, Multivitamin tablets, Protein powder blends, Nutraceutical tablets, Effervescent tablets, Omega-3 capsules, Calcium tablets, Dietary supplements

- Steps before

- Purification, Drying, Emulsification, Grinding

- Steps after

- Drying, Tableting, Tablet Coating

- Input ingredients

- API, OSD, health food, powder, solid

- Output ingredients

- granules, tablets, coated tablets

- Market info

- Austar is known for specializing in the design and manufacture of engineered-to-order industrial equipment, particularly in the pharmaceutical and biotechnology sectors, offering solutions that focus on quality, innovation, and meeting specific customer requirements.

- Pilot Scale Capacity

- 20 kg/h

- Commercial Scale Capacity

- > 2000 kg/h

- Process Automation

- Integrated with automatic control system

- Patented Technology Integration

- PAT technology for on-line monitoring

- Explosion-proof Compliance

- ATEX explosion-proof certification

- Granulating Process

- Continuous wet granulation

- Feeding Method

- Auto loss-in-weigh feeding

- Granulation Method

- Horizontal fluid bed processor

- Coating Process

- Top-spray granulating, bottom-spray pellet coating

- Data Integrity Compliance

- Meets EMA, FDA requirements

- Working mechanism

- Continuous wet granulation

- Integrated steps

- Feeding, mixing, granulating, drying, tableting, coating

- Automation level

- Integrated PAT for on-line monitoring

- Batch vs. continuous operation

- Continuous

- Compliance

- ATEX explosion-proof certification

- Scalability

- Pilot scale (20kg/h) to commercial production (>2000kg/h)

- Customization flexibility

- Customized solutions for single line multiple products

- Process optimization

- Pilot scale testing and process optimization platform

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Applicable areas

- API, OSD, health food

- ATEX certification

- Yes

- FDA compliance

- Yes

- FDA materials

- Yes

- EU ATEX Explosion-proof

- Yes

- EMA data integrity

- Yes

- GMP Compliance

- Yes

- Footprint

- Compact and integrated design

- Feed method

- Auto loss-in-weight feeding

- Discharge method

- Continuous discharge

- Tank size

- Pilot scale

- Commercial scale

- > 2000 kg/h

- Control system integration

- PLC/SCADA

- Production scale options

- Pilot to commercial (>2000 kg/h)

- Flexible product line

- Multiple product capabilities

- Process integration

- Granulating, drying, tableting, coating

- Data monitoring

- PAT technology for on-line monitoring

- Compliance integration

- EMA, FDA data integrity

- Certification compliance

- ATEX explosion-proof