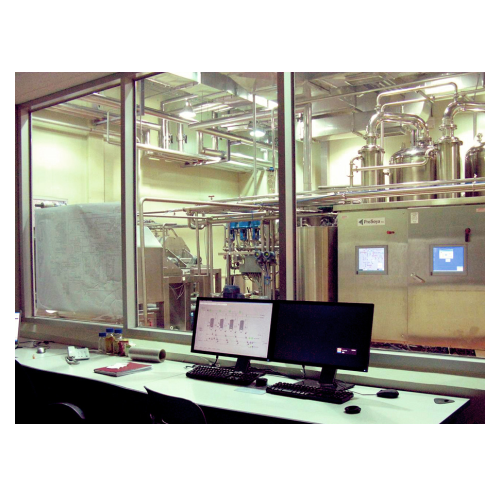

Soya protein isolate production line

Ensure the highest protein purity with this comprehensive production line designed to create superior plant-based protein products, essential for high-quality dairy alternatives and nutritional supplements.

Processes Soya Beans into Protein Isolate

The Soya Protein Isolate Processing Line from ProSoya is a comprehensive solution offering seamless integration into plant-based protein production. Using a multi-stage decanting system, it ensures continuous processing of dehulled and defatted soya beans to produce over 90% protein concentrate. Ideal for dairy alternatives and nutritional products, this line delivers on diverse end-products, such as protein-rich beverages and vegan protein shakes. With capacities ranging from 100 to 2000 kg/hr, it efficiently handles the complexity of protein isolation. Automation is achieved through PLC control with integration capabilities, optimizing energy use by 30% through variable-speed motor technology. Constructed in stainless steel for durability and chemical resistance, the system complies with industry standards. It features a CIP system for effortless cleaning and provides the flexibility of customizable configurations to meet specific production requirements.

Benefits

- Achieves high protein purity efficiently for diverse plant-based products.

- Enhances production output with continuous operation capabilities.

- Cuts energy usage by 30% with optimized motor controls, lowering operating costs.

- Facilitates easy integration with existing production lines via PLC automation.

- Ensures compliance with industry hygiene standards for safe food processing.

- Applications

- Supplements, Nutraceuticals, Dairy alternatives, Plant-based protein, Plant-based milk

- End products

- Plant-based protein bars, Soya protein isolate powder, High-protein plant-based milk products, Vegan protein shake mixes, Nutritional protein supplements, Protein-rich dairy alternative beverages

- Steps before

- Dehulling, Defatting, De-oiling, Flaking

- Steps after

- Spray Drying, Neutralizing, Packaging

- Input ingredients

- dehulled soybeans, defatted soybeans, de-oiled soya flour, de-oiled soya flakes, water, neutralising agent

- Output ingredients

- soya protein isolate, protein powder, protein solid with over 90% protein content

- Market info

- Prosoya is known for its expertise in manufacturing soy milk production equipment, providing innovative solutions for efficiently processing soybeans into soy milk and related products, highly regarded for its advanced technology and customizable engineering solutions.

- Capacity

- 100–2000 kg/h

- Protein Content

- >90% on dry basis

- Process Type

- Batch processing

- Separation Method

- Decanter centrifuge

- Drying Method

- Spray drying

- Input Material

- De-oiled soya flour or flake

- Primary Processing Method

- pH adjustment with acid

- Secondary Processing Method

- Neutralizing agent re-slurry

- Working mechanism

- Decanter centrifuge and spray drying

- Integrated steps

- De-oiling, neutralizing, spray drying

- Batch vs. continuous operation

- Batch

- Automation level

- Automation not specified, potentially manual intervention required

- CIP Principles

- Not specified

- Energy efficiency

- Not specified

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- N/A

- Tank shape and size

- N/A

- Feed method

- N/A

- Discharge method

- N/A

- Flow rate capacity

- 100–2000 kg/h

- Neutralizing agent type

- Customizable

- Centrifuge type

- Decanter centrifuge

- Spray drying options

- Customizable

- Control panel type

- Customizable