Bigbag discharge station

Efficiently manage bulk material unloading with this solution, which facilitates seamless discharging and dust-free handling, ensuring a cleaner production environment and minimizing material loss.

Efficiently Discharges and Extracts Dust from Bulk Solids

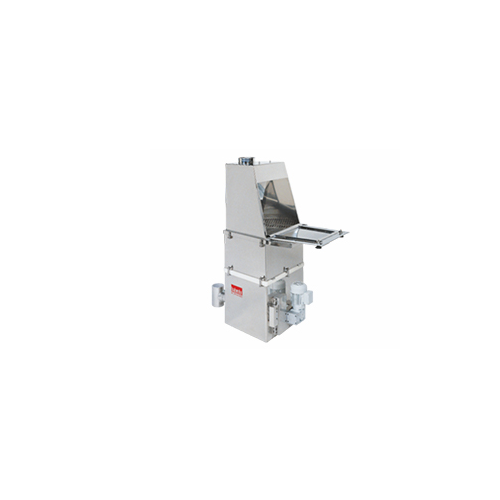

The BagDumper from SPS | Solids Process Solutions is designed to expertly handle the challenging task of bulk solids processing. Integrating seamlessly into production lines, this discharge station efficiently deals with both lined and unlined BigBags, featuring integral bin and volumetric activators for optimal material flow. Ideal for industries such as aquafeed, pharmaceuticals, and plastics manufacturing, it addresses the need for dust-free handling with an air pressure-cleaned dust filter and effective dust extraction via a built-in ventilator. The side-opening design facilitates hassle-free disposal of empty bags, ensuring a clean operational environment. Capable of continuous manual operation, the BagDumper supports various solid, powder, and granule types, enhancing your plant’s throughput while minimizing dust-related compliance issues. Customizable to meet specific operational demands, the system offers durability and efficiency, backed by SPS’s two decades of expertise in solid processing solutions.

Benefits

- Enhances operational efficiency with dust-free material handling, improving workplace safety.

- Streamlines disposal process via easy-access side-opening for empty bags.

- Maintains compliance with dust control regulations through integrated dust extraction and filtration.

- Increases production line efficiency with continuous manual operation capability.

- Customizable configuration allows for adaptation to varying material and processing needs.

- Applications

- Food, Feed, Recycling, Fine chemicals, Nutrition, Detergents, Compounding, Chemical, Pharma, Plastics, Minerals, Masterbatch, Aquafeed, Dairy, Petfood

- End products

- Detergent powders, Powdered milk, Dog kibble, Mineral powders, Food additives, Vitamin supplements, Chemical compounds, Plastic granules, Pigment masterbatches, Fish pellets, Recycled plastic pellets, Animal feed pellets, Protein powders, Pharmaceutical powders

- Steps before

- Material Unloading, Material Staging

- Steps after

- Dust Collection, Waste Disposal

- Input ingredients

- lined BigBags, unlined BigBags

- Output ingredients

- discharged material, dust-free disposal of empty bags

- Market info

- Discharge type

- BigBags lined/unlined

- Activators

- Integral bin activator / Integral volumetric activator

- Design

- Glovebox

- Dust filtration

- Air pressure cleaned dustfilter

- Dust extraction

- Ventilator

- Bag disposal

- Side-opening for dust-free disposal

- Discharge method

- Lined/Unlined BigBags

- Dust extraction

- Air pressure cleaned dust filter

- Automation level

- Manual operation with ventilator

- Cleaning method

- Air pressure-based dust removal

- Batch vs. continuous operation

- Batch

- Integrated steps

- Built-in venting and dust extraction

- Side-opening mechanism

- For dust-free empty bag disposal

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Discharge method

- Bag Emptying, BigBag Discharge

- Bag type compatibility

- Lined and unlined BigBags

- Dust extraction

- Ventilator, Air pressure cleaned dustfilter

- Dust disposal design

- Side-opening for dust-free disposal of empty bags

- Integral design options

- Integral bin activator, Integral volumetric activator

- Design features

- Glovebox design

- Discharge station type

- Lined / Unlined BigBags

- Integration options

- Integral bin activator / Volumetric activator

- Design features

- Glovebox design

- Dust control method

- Air pressure cleaned dustfilter / Ventilator for dust extraction

- Access design

- Side-opening for dust-free disposal