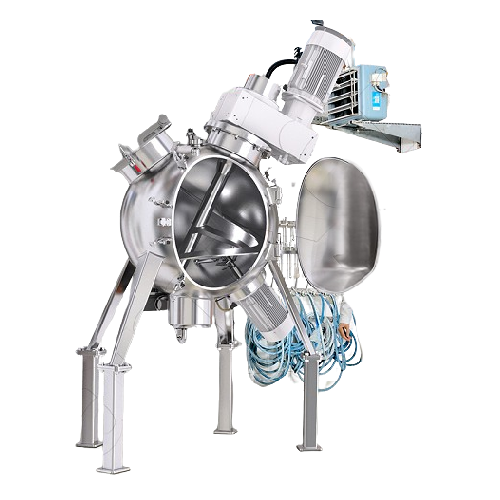

Spherical mixer for industrial mixing applications

Experience precise and efficient mixing with this hollow spherical mixer, designed for rapid distribution and desagglomeration across diverse material states—be it solids, liquids, or pastes—ensuring consistent product quality for demanding manufacturing processes.

Mixes and Distributes Powders and Liquids Efficiently

The SpherHelics® SH 400 from amixon® presents a revolutionary approach to mixing with its hollow spherical design. This mixer, equipped with an amixon®-typical spiral mixing tool, offers a versatile solution for industries such as food, pharmaceuticals, and chemicals. By rotating within a hollow sphere, it ensures rapid and homogeneous integration of ingredients—whether solid, liquid, or slurry. Ideal for applications such as producing protein powder, mixing cosmetics, and formulating 3D printer filaments, it can accommodate up to 400 liters, making it suitable for both pilot and batch operations.

The SpherHelics® emphasizes energy efficiency with low drive power requirements and offers exceptional distribution of liquid additions through its precision control. It promises quick and easy maintenance, featuring options for both dry and wet cleaning, including the fully automatic WaterDragon® system. Constructed from durable materials, it meets FDA, EHEDG, and 3-A Sanitary Standards, ensuring compliance and safety in sterile environments. With a customizable design, the SpherHelics® integrates seamlessly into existing production lines, offering unparalleled mixing capabilities and engineering support to meet specific operational needs.

Benefits

- Enhances product uniformity with rapid, thorough mixing for consistent quality.

- Lowers energy costs with efficient drive power and optimized motor control.

- Complies with high sanitation standards, ensuring safety in sensitive applications.

- Facilitates easy cleaning and maintenance with automated CIP options.

- Reduces cycle times significantly, boosting overall production efficiency.

- Applications

- Food, Powder metallurgy, Feed, Nutritional supplements, Infant formula, Fine ceramics, Plant-based food, Chemical industry, Hygiene and cosmetics, 3d printing, Herbs, Household detergents, Spices, Plastics, Pharmaceuticals

- End products

- Laundry detergent, Spice blends, Pharmaceutical tablets, Baby formula, Metal powders for additive manufacturing, Vitamin supplements, Facial creams, Ceramic powders, Herbal extracts, Protein powder, Plastic pellets, 3d printer filament, Plant-based meat analogues

- Steps before

- Purification, Drying, Emulsification, Grinding

- Steps after

- Sterilization, Packing, Coating, Tablet Pressing

- Input ingredients

- dry goods, moist goods, pasty goods, suspensions, liquids

- Output ingredients

- ideal mixing quality, short mixing times, quick and precise liquid distribution, excellent residual emptying

- Market info

- Amixon is renowned for designing and manufacturing high-quality mixing equipment, including powder mixers and vacuum dryers, for various industries such as food, pharmaceuticals, and chemicals, with a focus on precision, hygiene, and innovative mixing solutions.

- Mixing volume

- Up to 400 litres

- Mixing mechanism

- Spiral mixing tool

- Mixing axis orientation

- Vertical or inclined

- Drive power

- Low energy consumption

- Mixing time

- Very short

- Compliance

- FDA-compliant

- Materials compatibility

- Dry, moist, pasty goods, and liquids

- Pressure resistance

- Pressure-resistant double jacket

- Cleaning method

- Dry or wet, fully automatic with WaterDragon®

- Residual emptying

- Excellent due to ComDisc® tools

- Automation

- Automated cleaning options

- Working mechanism

- Hollow spherical mixing with spiral tool

- Batch vs. continuous operation

- Batch

- Automation level

- Manual / Fully automatic

- Cleaning method

- Simple and efficient cleaning, dry or wet, fully automatic with WaterDragon®

- CIP/SIP

- FDA-compliant sterile mixers

- Energy efficiency

- Low drive power and energy consumption

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Mixing type

- Dry, moist, pasty goods, suspensions, liquids

- Machine footprint

- Compact

- Tank shape

- Hollow spherical

- Capacity

- 400 litres

- Mixing tool orientation

- Vertical or inclined

- Control panel type

- Available upon request

- Discharge method

- ComDisc® tools for excellent residual emptying

- Mixing tool orientation

- Vertical or inclined

- Sterile mixer option

- FDA-compliant

- Reactor type

- Pressure-resistant double jacket

- Cleaning method

- Dry or wet, fully automatic with WaterDragon®