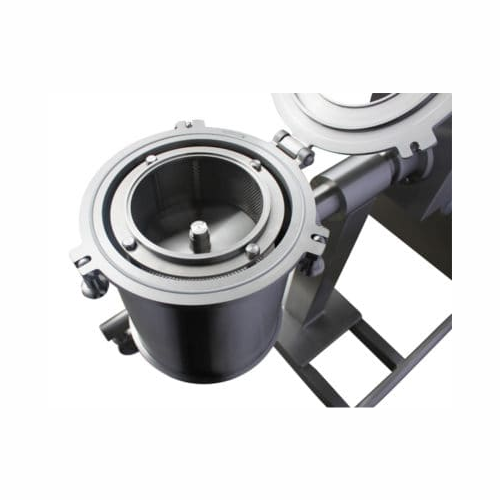

Centrifugal powder sifter for particle separation

Achieve consistent material quality with efficient powder sifting and de-lumping, ensuring the removal of foreign objects and maintaining product purity in your continuous processing lines.

Screens and De-lumps Powders Efficiently

The Kwik-Sift series from Hanningfield, including the KS05, KS10, and KS20 models, offers innovative centrifugal sifters tailored for efficient powder screening and de-lumping across diverse industries such as pharmaceuticals, nutraceuticals, and food and beverage. These sifters utilize a rotating mesh drum to deliver fast and effective screening, ensuring material integrity by filtering out foreign objects like nuts, bolts, and cable ties.

With applications ranging from powdered antibiotics to protein powders and powdered metals, the Kwik-Sift enhances purity and consistency in end-products. Its impressive processing capacity ranges between 5 to 23,000 kgs/hr, depending on the model, making it suitable for both small-scale and large-scale operations.

Designed for easy integration into your production line, the Kwik-Sift can be mounted in-line or used in a standalone configuration. It supports continuous, high-speed, in-line operations and features options for customization, including various mesh sizes and ATEX compliance for explosive environments.

Built from 316L and 304 stainless steel with FDA-compliant seals, this equipment ensures durability and corrosion resistance while maintaining GMP standards. Ease of maintenance is a hallmark, with quick mesh changes and optional breaker bars for de-lumping. Hanningfield also provides comprehensive engineering support to tailor each unit to specific process requirements.

Benefits

- Enhances product quality by effectively removing contaminants and foreign objects.

- Increases production efficiency with rapid screening and de-lumping capabilities.

- Supports versatile production lines with customizable mesh sizes and mounting options.

- Ensures regulatory compliance with FDA and ATEX standards.

- Lowers maintenance time with quick and easy mesh changes.

- Applications

- Powder screening, Oral solid dosage, Detergents, Nutraceuticals, Metals, Nuts, Chemical, Food and beverage, Spices, Powder processing, Cannabis, Sweeteners, Pharmaceuticals

- End products

- Chopped nuts, Cannabis oil, Powdered metals, Pharmaceutical tablets, Sugar substitutes, Baking powder, Detergent powder, Vitamin supplements, Bulk spices, Powdered antibiotics, Protein powder, Powdered drink mix

- Steps before

- Grinding, Material Handling, Mixing, Sieving

- Steps after

- Packaging, Tablet Pressing, Capsule Filling, Sterilization

- Input ingredients

- powder, drums, IBCs, big bags, agglomerated material

- Output ingredients

- sifted powder, retained alien objects, de-lumped material

- Market info

- Hanningfield Process Systems is known for manufacturing high-quality, customized process handling, and containment equipment for industries such as pharmaceutical, food, and chemical, specializing in milling, sieving, and powder handling solutions.

- Capacity

- 5 - 500 kgs/hr (10 - 1100 lbs/hr)

- Capacity

- 350 - 7500 kgs/hr (800 - 16500 lbs/hr)

- Capacity

- 1100 - 23000 kgs/hr (2400 - 52000 lbs/hr)

- Screen Diameter

- 83mm (3.25in)

- Screen Diameter

- 127mm (5")

- Screen Diameter

- 203mm (8")

- Motor Power

- 0.375 kW (0.5 HP)

- Motor Power

- 1.5 kW (2 HP)

- Motor Power

- 4.0 kW (5 HP)

- Weight

- 40 kgs (90 lbs)

- Weight

- 140 kgs (310 lbs)

- Weight

- 160 kgs (350 lbs)

- Noise Level

- <78dB

- Construction Material

- 316L stainless steel (1.4404)

- Construction Material

- 304 stainless steel (1.4301)

- Compliance

- FDA Compliant

- Compliance

- ATEX / Ex-proof

- Working Mechanism

- Centrifugal Screening

- Integrated Steps

- De-lumping and Deagglomeration

- Operation Type

- Batch / Inline Continuous

- Screen Changeover Time

- , lt

- 2 minutes

- Automation Level

- Manual / PLC

- Cleaning Method

- Requires disassembly

- Typical Noise Level

- , lt

- 78dB

- Abrasion resistance

- Yes

- Biological compatibility

- FDA compliant

- Cleanability

- Easy to clean (CIP-friendly)

- Corrosive resistance (e.g. acids)

- 316L stainless steel (good resistance)

- Density/particle size

- Variety of mesh sizes available

- Agglomeration risk

- Yes/with spoiler arm

- Container compatibility

- Drums, IBCs, Big Bags

- Foreign object capture

- Nuts, bolts, washers, cable ties

- Sifting efficiency

- Fast and effective

- De-lumping capability

- Yes, with spoiler arm

- Material integrity

- Guarantees integrity

- Mesh size range

- Various sizes available

- Powder type

- Various powders

- Processing method

- In-line, gravity feed, vacuum transfer

- Throughput capacity

- 5 - 23, 000 kgs/hr

- Machine weight

- 40 kgs (90 lbs) for KS05, 140 kgs (310 lbs) for KS10, 160 kgs (350 lbs) for KS20

- Material of contact parts

- 316L stainless steel

- Material of non-contact parts

- 304 stainless steel

- Screen diameter

- 83mm (3.25in) for KS05, 127mm (5") for KS10, 203mm (8") for KS20

- Motor power

- 0.375 kW (0.5 HP) for KS05, 1.5 kW (2 HP) for KS10, 4.0 kW (5 HP) for KS20

- Noise level

- <78dB

- Discharge method

- Gravity feed or vacuum transfer

- Mounting solutions

- Mobile frame, swing-arm, fixed post, hoist mounted

- Inlet and outlet configurations

- Hand-feed chute, valve assemblies, tri-clover connections, vacuum adaptors

- Spoiler arm arrangement

- Single or dual

- Mounting Solutions

- Mobile frame, swing-arm, fixed post, hoist mounted

- Inlet and Outlet Configurations

- Hand-feed chute, valve assemblies, tri-clover connections, vacuum adaptors