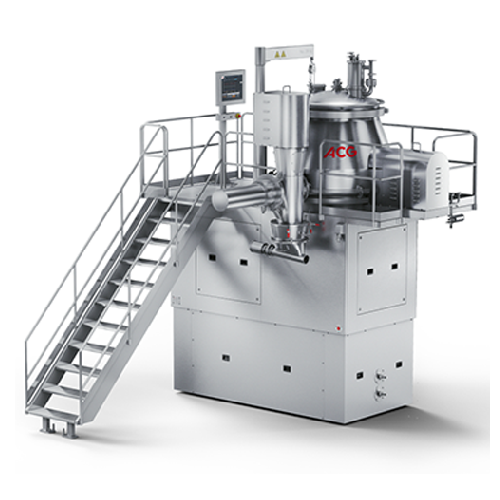

High-shear mixer for large-scale pharmaceutical production

Optimize your granulation process with an advanced high-shear mixer, designed for consistency and efficiency in mixing pharmaceutical powders and nutraceuticals, ensuring uniform particle distribution in large production batches.

Mixes and Granulates Pharmaceutical Powders

The HSM 1200 High-Shear Mixer from ACG is a critical component for pharmaceutical and nutraceutical manufacturers focusing on efficient granulation and mixing. Designed to handle large production batches, this mixer is known for its superior centrifugal force achieved through a Z-shaped impeller and multi-blade chopper. It ensures uniform binder distribution and optimal particle-size distribution, especially valuable in producing effervescent tablets and protein powders.

Operating with a working volume ranging from 360 to 960 liters, it seamlessly integrates into granulation trains or functions independently, offering flexibility in production lines. Its PLC-controlled system promotes batch operations and high-speed processing, ensuring consistent output. The HSM 1200 reduces energy consumption via optimized motor control and enhances wash-in-place efficiency with integrated cleaning nozzles for swift and dust-free maintenance.

Constructed to adhere to GMP compliance with an ergonomic design, it offers the advantage of easy access for operation and maintenance. With multiple systems for charging and discharging and a highly efficient vent air filtration, the machine supports smooth and uncontaminated processing cycles. Configurations are available to meet your specific operational demands, backed by ACG’s expertise from handling over 1,000 formulations.

Benefits

- Enhances production efficiency with quick, dust-free material transfer.

- Optimizes particle-size distribution for consistent product quality.

- Reduces cleaning time with integrated wash-in-place features.

- Supports GMP compliance with an ergonomic, accessible design.

- Adapts to batch or large-scale operations for flexible manufacturing.

- Applications

- Nutraceuticals, Pharmaceutical powder, Supplements, Pharmaceutical tablets

- End products

- Protein powders, Herbal supplement powders, Vitamin c tablets, Calcium supplements, Over-the-counter analgesic tablets, Amino acid tablets, Multivitamin tablets, Effervescent tablets

- Steps before

- Formulation Development, Material Loading

- Steps after

- Tablet Compression, Drying, Coating, Packing

- Input ingredients

- raw materials, wet granulation compounds

- Output ingredients

- granulated product, mixed formulation

- Market info

- ACG World is known for its expertise in manufacturing pharmaceutical and nutraceutical processing and packaging machinery, offering innovative equipment solutions and maintaining a strong reputation for quality and reliability in the global market.

- Working volume

- Min 360 l - Max 960 l*

- Model size / Capacity

- HSM 1200

- Model size / Capacity

- HSM 150

- Model size / Capacity

- HSM 300

- Model size / Capacity

- HSM 400

- Model size / Capacity

- HSM 600

- Model size / Capacity

- HSM 800

- Impeller type

- Z-shaped impeller

- Chopper type

- Multi-blade chopper

- Vent air filtration system

- High-efficiency

- Cleaning method

- Wash-in-place (WIP)

- Integrated cleaning nozzles

- Product bowl and discharge

- Batch vs. continuous operation

- Batch

- Automation level

- Integrated with PLC/SCADA

- CIP/SIP

- Wash-in-place (WIP)

- Cleaning method

- Integrated cleaning nozzles

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product bowl design

- Ergonomic

- Access platform position

- Perfectly positioned

- Impeller type

- Z-shaped

- Chopper blade type

- Multi-blade

- Vent air filtration system

- Integrated

- Cleaning nozzles

- Integrated

- Working volume

- 360 l - 960 l

- Control panel type

- HMI / PLC

- Integration possibilities

- Standalone/Granulation train integration

- Impeller type

- Z-shaped impeller

- Chopper type

- Multi-blade chopper

- Cleaning system

- Integrated cleaning nozzles

- Ventilation system

- Efficient vent air filtration