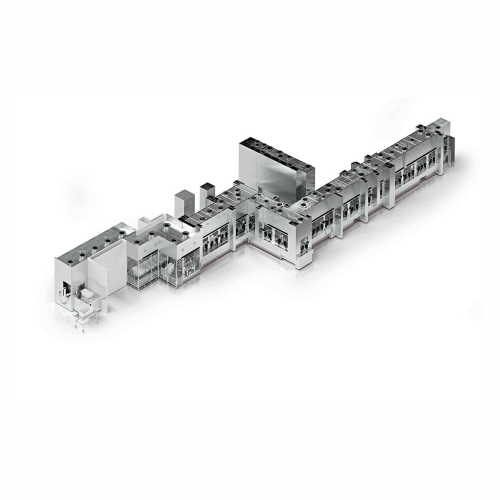

Sterile bag filling and closing system

Ensure precision and sterility in multi-chamber bag filling for liquid and powder pharmaceuticals, enhancing your production line with high-speed, automated operations that minimize contamination risk.

Fills and Closes Sterile Bags for Pharmaceuticals

The SMART DB2 from IMA Group is a sterile bag filling and closing machine specifically engineered for pharmaceutical and biotech industries, tackling challenges in aseptic processing of liquids and powders. This advanced system automates the entire process, from loading and decontamination of sterile bags to precise filling and secure closing. Utilizing dosing disks for powders and mass-flow technology for liquids, it ensures accurate fills in multi-chamber, ready-to-use bags. With a throughput of up to 42 bags per minute, it supports high-volume production. Integrated CIP/SIP technology facilitates efficient in-place cleaning and sterilization, maintaining operational sterility and compliance with industry regulations. Advanced robotics minimize human intervention, while isolation technology protects sterility, making it ideal for manufacturing intravenous solutions, vaccine bags, and chemotherapy mixtures.

Benefits

- Optimizes production efficiency with high-speed filling up to 42 bags per minute.

- Ensures product integrity by maintaining sterile conditions through automated processes.

- Enhances accuracy with 100% weight verification for both liquid and powder fills.

- Minimizes manual intervention with robotic technology, reducing potential contamination risks.

- Complies with stringent pharmaceutical standards, ensuring regulatory adherence.

- Applications

- Sterile liquid formulations, Pharmaceutical powders, Multi-chamber sterile bags

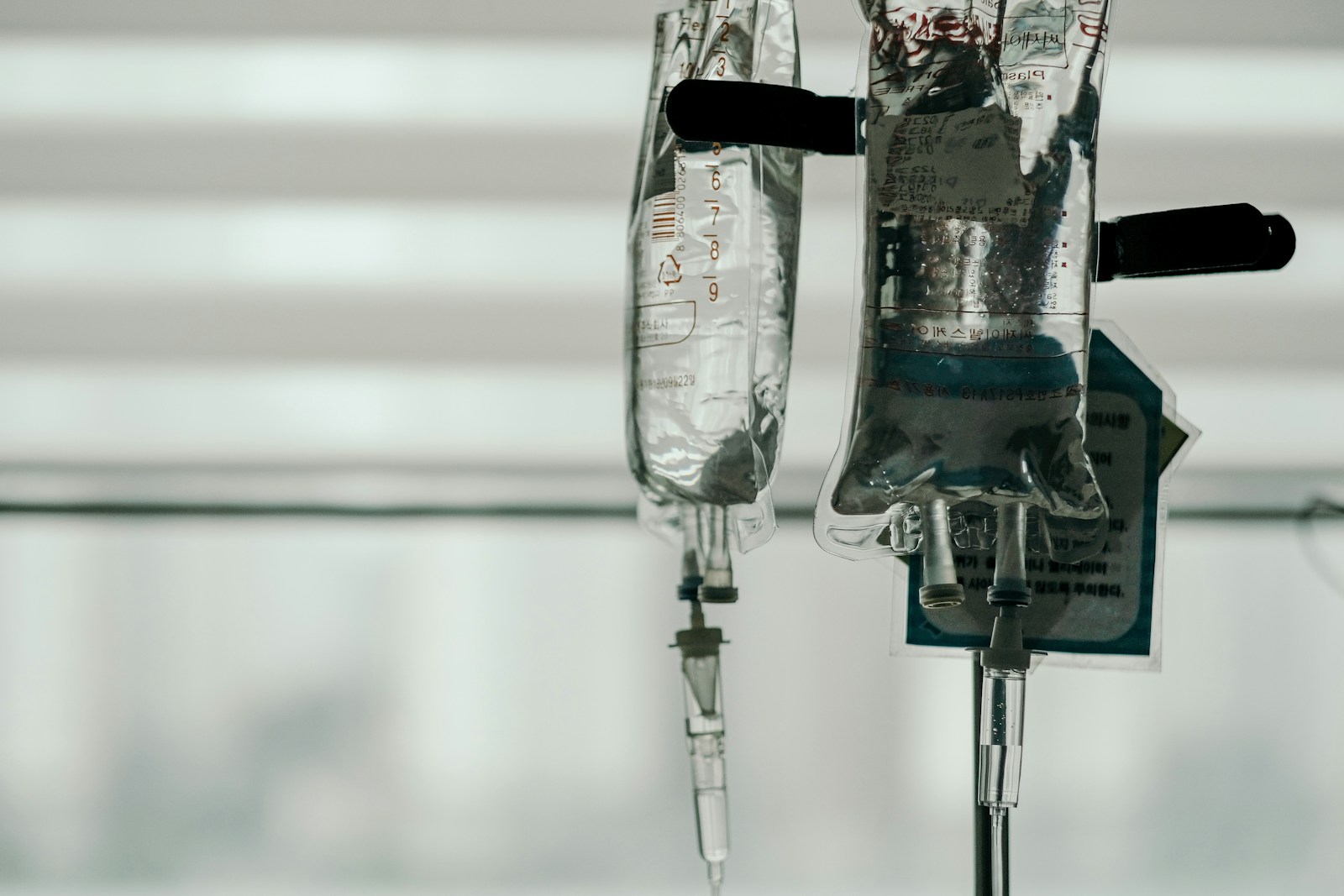

- End products

- Vaccine storage bags, Blood and blood component bags, Chemotherapy drug mixtures, Protein powder supplements, Dialysis solutions, Total parenteral nutrition bags, Antibiotic powder formulations, Intravenous saline solutions

- Steps before

- Automatic loading, Decontamination of sterile bags

- Steps after

- Final collection, Recapping, Vacuum forming, Check-weighing

- Input ingredients

- sterile empty bags, powder drugs, liquid products

- Output ingredients

- filled sterile bags, multi-chamber bags, Ready-To-Use sterile bags

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Batch production output

- Up to 42 bags per minute

- Filling volume liquid section

- 50 ml

- Filling volume powder section

- 3.5 grams

- Sterilisation Assurance Level

- SAL compliant

- Tare and gross check-weighing

- Automatic 100%

- CIP SIP system

- Integrated

- Automation

- High-level with robotic interactions

- Contamination risk containment

- Isolation technology

- Automation level

- Robot interactions

- Batch vs. continuous operation

- Batch

- CIP/SIP

- Integrated CIP/SIP system

- Cleaning method

- CIP / SIP

- Changeover time

- Minimized due to automation

- Biological compatibility

- Yes

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- High

- Density/particle size

- 0.5–2.5 g/cm³

- Machine footprint

- Compact design

- Bag size

- Defined according to customer requirements

- Bag filling capacity

- Up to 42 bags per minute

- Control panel type

- Automated with minimal human intervention

- Control panel type

- Touchscreen HMI

- Integration possibilities

- Compatibility with existing automation systems