Curd handling and cutting for cheese production

Optimize curd processing with precise cutting and feeding, ensuring consistent quality for cheese variants like mozzarella and feta while reducing waste and manual handling.

Processes and Feeds Curd for Dairy Production

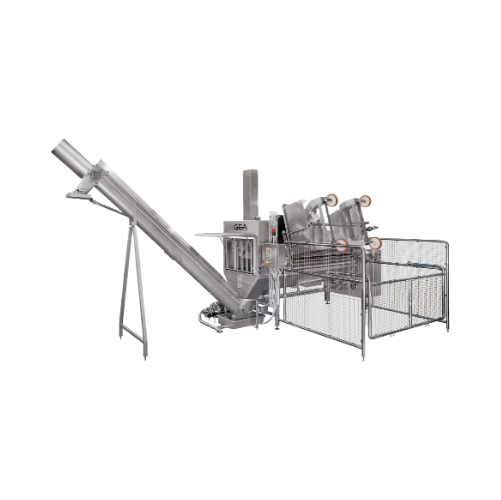

The feeder cutter unit from GEA is an automated, high-efficiency system designed for precision in dairy and food processing. Utilizing a pneumatic-driven curd cutter with an independent control system, it achieves consistent cut sizes in products like mozzarella, feta, and paneer. The integration of an accumulation vat, equipped with a 500 mm auger, makes it ideal for both manual and automatic operations, while maintaining gentle curd handling to preserve quality. With a capacity of receiving up to 2,000 kg of product and featuring AISI 304 stainless steel construction, it withstands harsh processing environments. This unit supports energy efficiency and reduces operating costs through optimized motor control. GEA provides tailored bi-directional chutes for multi-machine integration, enhancing workflow in continuous and slurry production lines. The design incorporates electro-mechanical safety features and is compliant with key industry standards, making it suitable for demanding food and dairy applications.

Benefits

- Enhances product consistency and quality through precise, programmable curd cutting.

- Lowers operational costs with energy-efficient auger and pneumatic systems.

- Increases production flexibility, handling both manual and automated processes.

- Ensures safety with comprehensive electro-mechanical protection features.

- Simplifies integration with existing systems, facilitating continuous workflow in dairy production lines.

- Applications

- Protein processing, Food processing, Curd processing, Cheese making, Liquid processing, Dairy

- End products

- Feta cheese, Curd blocks, Greek yogurt, Processed cheese, Cream cheese, Mozzarella cheese, Protein isolates, Ricotta cheese, Cottage cheese, Paneer

- Steps before

- Curd Transfer, Curd Accumulation

- Steps after

- Curd Stretching, Cut Curd Conveying

- Input ingredients

- curd, whey

- Output ingredients

- cut curd slices, pipendal strips, stretched curd

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Auger Size

- 500 mm

- Vat Capacity

- 1000-2000 kg

- Material

- AISI 304 Stainless Steel

- Automation

- Pneumatically Controlled

- Cutting Configuration

- Parallel Pipelines

- Control Panel

- Waterproof

- Drive Type

- Electro-mechanical

- Rotational Control

- Continuous/Intermittent

- Pneumatic Control

- Bi-directional

- Working mechanism

- Pneumatic system

- Integrated steps

- Curd transfer and cutting

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC-controlled

- Energy efficiency

- Low operating costs

- Cleaning method

- Electro-mechanical protection

- Stainless Steel Grade

- AISI 304

- Corrosion Resistance

- High

- Compatibility with Food Products

- Dairy

- Material

- AISI 304 stainless steel

- Vat capacity

- 1000-2000 kg

- Auger size

- 500 mm

- Control panel type

- Waterproof

- Discharge method

- Pneumatically controlled curd cutter

- Auger loader

- At the end of the accumulation vat

- Control panel type

- Waterproof

- Auger rotation programming

- Continuous / Intermittent

- Pneumatic blade programming

- Adjustable downstroke frequency

- Cut curd thickness adjustment

- precise

- Material

- AISI 304 Stainless Steel