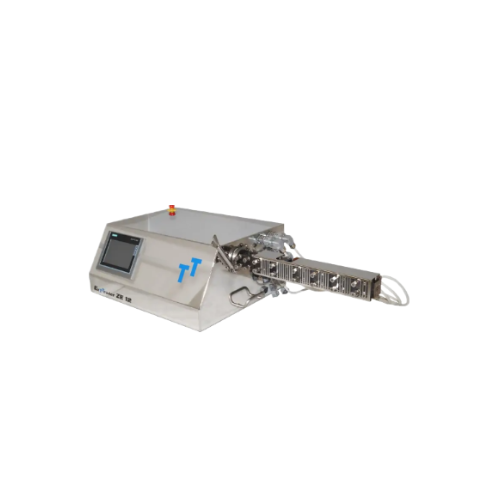

Table-top mini extruder for precision material processing

Achieve precise control over complex formulations with this flexible mini extruder, perfect for research and development scenarios where adaptability and precision in handling a variety of materials are crucial.

Customizes and Extrudes Pharmaceutical and Chemical Powders

The ZE 12 HMI from Three-Tec GmbH is a versatile table-top mini extruder engineered for the precise demands of pharmaceuticals and chemical processing. What sets this equipment apart is its ability to handle diverse processing tasks through configurable screw segments, permitting operations like conveying, kneading, and reverse conveying. With applications extending to biopharmaceuticals and fine chemicals, it excels in producing high-quality tablet granulations and supplements, such as Vitamin C tablets and enzyme-enhanced detergents.

Operating on a compact scale, the ZE 12 HMI offers customizable temperature settings up to 400 °C, alongside options for water, air, or liquid nitrogen cooling. Despite its reduced size, it is fitted with a touch panel for intuitive control and pressure sensors for accurate monitoring. Its construction features stainless steel 316L, ensuring robustness and compatibility with a wide range of materials. Designed to meet stringent pharmaceutical requirements, this extruder integrates seamlessly into research and development environments, offering flexibility and precision to material development companies and laboratories.

Benefits

- Enhances formulation precision with customizable screw segments for targeted processing.

- Minimizes energy usage through efficient heating options, offering up to 400 °C temperature control.

- Reduces setup time with quick adjustment capabilities via a responsive touch panel interface.

- Ensures material compatibility and durability with corrosion-resistant stainless steel construction.

- Facilitates diverse application needs with optional cooling methods tailored to specific material requirements.

- Applications

- Supplements, Vitamins, Metal powders, Fine chemicals, Detergents, Nutraceuticals, Pharmaceutical powder, Biopharmaceuticals, Enzymes, Coating materials, Minerals

- End products

- Calcium carbonate tablets, Lyophilized vaccines, Vitamin c tablets, Magnesium stearate powder, Herbal extract capsules, Multi-vitamin gummies, Zinc oxide coatings, Copper metal powder, Protein powder supplements, Tablet granulation, Iron supplement capsules, Enzyme-enhanced laundry detergents

- Steps before

- Material Preparation, Ingredient Feeding, Blending, Pre-Heating

- Steps after

- Product Cooling, Cutting and Shaping, Packaging, Quality Inspection

- Input ingredients

- Output ingredients

- Market info

- Three-Tec is known for its expertise in manufacturing precision dosing and feeding systems for industrial applications, with a strong reputation for customizable engineered-to-order equipment and innovative solutions tailored to specific customer needs.

- Screw Diameter

- 12 mm

- Max. Pressure

- 250 bar

- Max. Torque

- 20 Nm

- Max. Temperature

- 230 °C (400 °C optional)

- Heating Zones

- 1-8

- Heating Time

- 5 min (100 °C) / 14 min (200 °C)

- Material

- Stainless Steel 316 L (1.4404)

- L/D Ratio

- 15

- Operation

- Touch panel

- Dimensions (L x W x H)

- 650 x 400 x 260 mm

- Weight

- ≈ 51 kg

- Cooling options

- Water / Air / Liquid nitrogen

- Pressure measurement

- At the nozzle

- Feeder type

- Automatic solid or liquid

- Screw configuration

- Co-rotating

- Screw customization

- Conveying / Kneading / Mixing / Compacting / Pressing / Decompressing / Reverse conveying

- Operation interface

- Touch panel

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleanability

- Stainless steel 316 L

- Corrosive resistance (e.g. acids)

- Stainless steel 316 L

- Machine footprint

- 650 mm (excl. barrel) x 400 mm x 260 mm

- Weight

- ≈ 51 kg

- Screw diameter

- 12 mm

- L/D ratio

- 15

- Construction material

- Stainless steel 316L (1.4404)

- Cooling options

- Water, air, liquid nitrogen

- Operation control

- Touch panel

- Cooling Option

- Water / Air / Liquid Nitrogen

- Pressure Measurement

- Available

- Feeder Type

- Automatic Solid / Liquid Feeders

- Screw Segment Customization

- Conveying / Kneading / Mixing / Compacting / Pressing / Decompressing / Reverse Conveying

- Operation Panel Type

- Touch Panel