Nutraceutical products processing and packaging

Streamline your nutraceutical production with versatile equipment capable of handling everything from capsule filling to freeze drying, ensuring optimal quality and efficiency in processing herbal supplements, vitamin tablets, and functional sweets.

Fills and Packages Nutraceutical Capsules and Granules

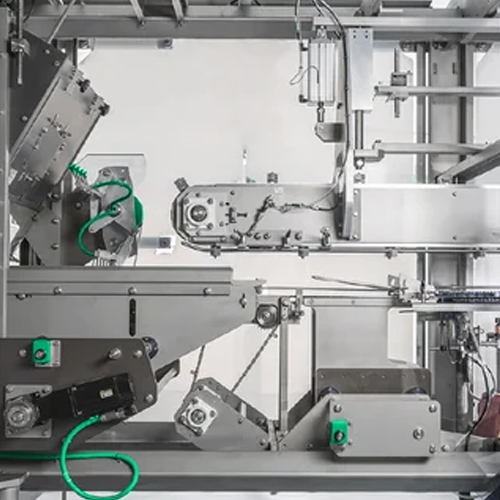

Syntegon’s Nutraceutical Granule and Capsule Filling System offers a comprehensive solution tailored for the needs of nutraceutical producers and pharmaceutical manufacturers. Designed to improve operational efficiency, this system precisely fills capsules and packages granules, ensuring accurate dosage and minimal waste. Integrating seamlessly into both batch and continuous operations, it supports various production scales. The system accommodates a wide array of applications from encapsulating omega-3 capsules and vitamin tablets to packaging protein powder sachets and probiotic gummies.

With automation at its core, the system is equipped with PLC controls for streamlined operations and offers remote monitoring for enhanced production oversight. The equipment is constructed with durable stainless steel options, ensuring compliance with GMP standards and reliability under extensive operational use. Maintenance is efficient with an integrated CIP system that allows thorough cleaning without manual intervention. Additionally, customization options are available to adapt filling and packaging capabilities to specific product requirements, providing engineering support to optimize your production line.

Benefits

- Ensures precise dosage and minimizes material waste, enhancing product consistency.

- Increases operational efficiency with seamless integration into existing production lines.

- Reduces labor costs through remote monitoring and PLC-controlled automation.

- Adapts to various production scales and product types with customizable features.

- Maintains compliance with GMP standards, ensuring high-quality production processes.

- Applications

- Jellies, Hard candies, Nutraceuticals, Granules, Functional sweets, Tablets, Capsules, Dietary supplements

- End products

- Energy-boosting hard candies, Probiotic gummies, Herbal dietary supplements, Vegetarian omega-3 soft gels, Vitamin c tablets, Calcium chews, Vitamin d granules, Protein powder sachets, Omega-3 capsules, Collagen jellies

- Steps before

- Granule Formation, Capsule Dosing, Tablet Formulation

- Steps after

- Packing, Blister Packaging, Labeling

- Input ingredients

- granules, capsules, tablets, jellies, hard candies

- Output ingredients

- processed nutraceutical products, sustainable packaging, paper-based blister packaging, tablets, capsules, functional sweets

- Market info

- Syntegon is known for its expertise in processing and packaging technology, offering innovative solutions for the food and pharmaceutical industries. It has a strong reputation for advanced equipment, sustainability, and customer-oriented service.

- Granule Processing Capability

- Tablet pressing, capsule filling

- Capsule Dosing Flexibility

- Hard capsules

- Tablet Forming Cost Efficiency

- Organic, clean label

- Packaging Innovation

- Paper-based blister

- Automation

- Manual / Auto

- Sustainability

- PET / Glass replacement

- Filling Systems

- Isolator, Barrier Systems

- Filling Type

- Liquid / Dry

- Filling Options

- Syringe / Cartridge / Vial

- Inspection Systems

- Visual / CCI / Inline

- Paper Blister Push-through

- Easy removal

- Carton Packaging

- Cartoning / Case Packing

- Capping,Coding

- Coding options

- Freeze Dryer

- FFPmicroBatch

- Handling System

- RTU Upstream / Downstream

- Continuous Manufacturing

- Tablets, Capsules, Sweets

- Tablet Compression

- High Shear Mixer

- Packaging Type

- Sachets, Stickpacks

- Capsule Filling Type

- GKF Series

- Cleaning Method

- Depyrogenation

- Lid / Closure Type

- Screw / Press

- Pure Media Generation

- Membrane / Distillation

- Fluid Bed System

- Drying / Coating

- Sterilization

- Tray loading

- Visual Inspection

- Inline / Semi-Automatic

- Tray Loading

- Sterilization

- Functional Sweets Form

- Tablets, Gummies

- Coating Method

- Tablet Coating

- Aroma Protection

- Aroma sealing

- Cupping Packaging

- Bottle Filling

- Syringe Batch Filling

- FFPmicroBatch

- Robotic Solutions

- Confectionery Processing

- Bioprocessing System

- Liquid Fill, Finish

- High Shear Mixing

- Tablets, Capsules

- Batch vs. continuous operation

- Batch

- Automation level

- PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Changeover time

- Quick changeover for flexibility

- Energy efficiency

- Optimized for low energy consumption

- Air incorporation control

- Controlled air incorporation for quality

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container Size and Shape

- Variable

- Machine footprint

- Compact

- Control panel type

- Touchscreen Interface

- Discharge method

- Gravity / Pneumatic

- Control panel type

- Touchscreen / Push-button

- HMI type

- PLC / SCADA

- Integration possibilities

- ERP / MES

- Compact design

- Yes

- Material construction

- Stainless Steel

- Customizable output configurations

- Multi-line / Multi-format

- Discharge method

- Conveyor / Gravity

- Remote access capabilities

- Yes

- Modular design

- Yes