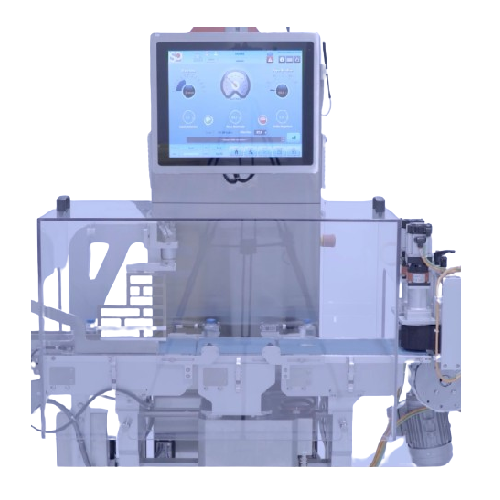

High precision pharmaceutical checkweigher

Ensure precise weight compliance in high-speed production lines with this advanced checkweighing solution, designed to streamline sorting and classification while maintaining optimal product integrity and reducing regulatory compliance risks.

Weighs, Sorts, and Ensures Product Compliance

The GXP-30 LIBRA by Siempharma is a robust checkweigher, purpose-built for pharmaceutical and nutraceutical packaging environments. This equipment excels by offering high-speed, precise weighing and sorting capabilities, handling up to 300 pieces per minute with seamless integration into existing production lines. Its sophisticated Electro Magnetic Force Restoration (EMFR) weigh cell provides rapid and accurate weight measurements, ensuring that only compliant products proceed along the packaging stage.

Designed for continuous, automated operations, the GXP-30 LIBRA features a lightweight conveyor system paired with anti-vibration servomotors to facilitate stable and efficient product transport. The device is ideal for a range of solid products including capsules, softgel, vitamin, and effervescent tablets, offering 100% product checks with real-time monitoring via an intuitive Touch Screen HMI.

Constructed from stainless steel for enhanced stability and reduced vibration, this checkweigher is compliant with Industry 4.0 standards and meets GMP regulations. It’s equipped with automatic rejection stations that employ sorters such as pushers or air blasts to remove non-compliant items without disrupting the production flow. The modular design and user-friendly interface allow for swift operator access, inspection, and maintenance. Customization options are available with comprehensive engineering support to perfectly align with your production requirements.

Benefits

- Ensures precise quality control with 100% product compliance checks.

- Enhances operational efficiency by processing up to 300 items per minute.

- Minimizes production interruptions with automated rejection of non-compliant products.

- Facilitates quick adaptation to production changes with an intuitive user interface.

- Complies with Industry 4.0 standards, enabling advanced data integration and monitoring.

- Applications

- Nutraceuticals, Nutraceutical supplements, Pharmaceutical tablets, Pharmaceuticals

- End products

- Protein powders, Multivitamin tablets, Vitamin tablets, Herbal supplements, Softgel tablets, Effervescent tablets, Omega-3 capsules, Capsules

- Steps before

- Filling, Capping

- Steps after

- Packing, Inspection

- Input ingredients

- pharmaceutical products, nutraceutical products, glass containers

- Output ingredients

- checked pharmaceutical products, checked nutraceutical products, correctly sorted products

- Market info

- Speed

- Up to 300 pcs/min

- Accuracy

- High precision

- Automation

- Touch Screen HMI

- Conveyor System

- Three conveyor belts

- Weighing Technology

- Electro Magnetic Force Restoration (EMFR)

- Reject Mechanism

- Automatic rejection station

- Load Sensor

- Maximum load sensor

- Weight Check

- 100% product checks

- Working mechanism

- Electro Magnetic Force Restoration (EMFR)

- Integrated steps

- Infeed, weighing, outfeed

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual

- Weight determination

- High precision

- Product monitoring

- 100% product checks

- Sorting capabilities

- Pusher, air blast

- Corrosive resistance (e.g. acids)

- Stainless Steel construction

- Cleanability

- Designed in accordance with GMP standards

- Product Monitoring

- 100% product checks

- Sector Compatibility

- Pharmaceutical, Nutraceutical

- Machine Footprint

- Compact, suitable for medium-range applications

- Structure Material

- Stainless steel

- Conveyor System

- Lightweight, three conveyor belts for infeed, weighing, and outfeed

- Control Panel Type

- Touch Screen HMI

- Control panel type

- Touch Screen HMI

- Integration standard

- INDUSTRY 4.0 compliant

- Compliance

- CFR21 part 11 / EU ANNEX 11