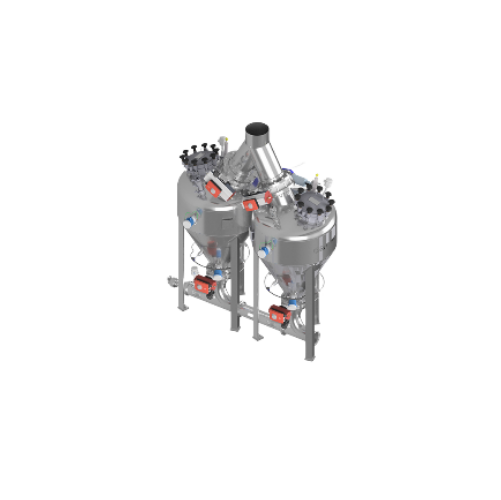

Dense phase pressure conveying system

Efficiently transport high-capacity powders across long distances with precision and reduced wear, ensuring delicate and abrasive materials remain intact during processing.

Conveys and Separates Industrial Powders Efficiently

The Dense Phase Pressure Conveying System from GEA efficiently transports powders and granules across various industries, including food, pharmaceuticals, and chemicals. Utilizing compressed air, it conveys materials with low velocity to minimize abrasion and degradation. Ideal for handling protein powders, pharmaceutical excipients, and metal powders for additive manufacturing, this system manages up to 30 tonnes per hour over distances exceeding 300 meters. Automation is streamlined through PLC controls, enhancing integration into existing lines. The system supports customizable features, such as air injectors and pulse air injection, to optimize air consumption and material flow. Constructed in stainless steel, it adheres to sanitation standards and offers ease of cleaning. Whether configured for batch or continuous operations, this system ensures reliable and adaptable material handling tailored to your specific needs.

Benefits

- Enhances product integrity by minimizing material degradation through low-velocity transport.

- Increases operational efficiency by conveying materials over long distances without significant pressure loss.

- Lowers maintenance costs with durable construction and extended service life for abrasive handling.

- Adapts to diverse applications with customizable air injection and specialized material options.

- Ensures sanitary operations with easy-to-clean stainless steel designs compliant with industry standards.

- Applications

- Food, Chemicals, Metal powders, Personal care products, Gas, Energy, Beverage, Pharmaceutical powder, Oil, Minerals, Dairy

- End products

- Protein powders, Cosmetic pigments, Catalyst powders, Powdered detergents, Milk powder, Metal powder for additive manufacturing, Petroleum coke, Instant coffee granules, Pharmaceutical excipients, Mineral salts

- Steps before

- Material Preparation, Pre-Mixing, Feeding into Pressure Pot

- Steps after

- Separation of Air and Product, Product Discharge, Quality Control

- Input ingredients

- friable materials, abrasive materials, bulk powders, granules, high capacity materials

- Output ingredients

- conveyed product, separated materials, processed powders, destination product

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Convey Rates

- < 30 tonnes/h

- Convey Distances

- short distances to > 300 m

- Air mover

- Compressor (screw, rotary, reciprocating)

- Conveying Pressure

- < 6 Barg

- Material Air Ratios

- High

- Operation

- Batch

- Conveying mechanism

- Dense phase pressure

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Batch

- Air pressure control

- Multiple air control valves

- Convey velocity

- Low to moderate

- Safety features

- High pressure safety measures

- Energy efficiency

- Optimized air consumption

- Adaptability

- Adjustable for difficult materials

- Abrasion resistance

- Yes

- Cleanability

- Meets USDA 3A Standards

- Density/particle size

- Variable (0.5–2.5 g/cm³ / customizable particle size)

- Corrosive resistance (e.g. acids)

- Stainless steel option available

- Twin pressure pot system

- Yes

- Pipeline material

- Stainless Steel

- Sanitary design

- USDA 3A Standards

- Expandable design

- Stepped lines

- Valves configuration

- Multiple air control valves

- Batch operation system

- Batch

- Inline sampling system

- Yes

- Cleaning access

- Polished design

- Air injection system

- Pulsed/Discrete slugs

- Material fluidization option

- Air injectors

- Pressure pot type

- Single or Twin

- Construction material

- Stainless Steel

- Optional systems

- Inline sampling / Metal detection / Magnetic separation

- CIP design

- Demountable, polished to USDA 3A standards

- Piping configuration

- Stepped lines

- System operation

- Batch basis