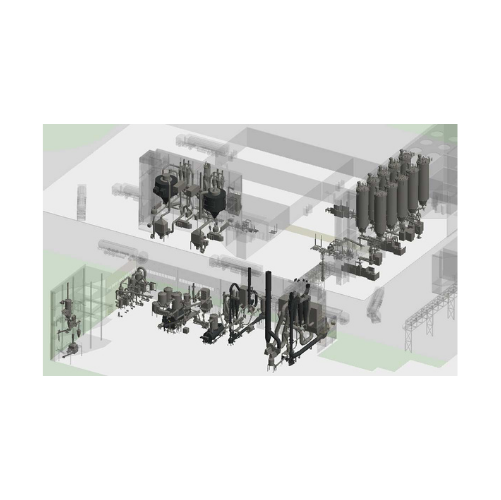

Corn wet milling plant drying systems

Optimize corn processing efficiency with integrated drying and dewatering systems designed to enhance product quality, reduce operational bottlenecks, and streamline production lines from raw corn to finished high-value products.

Processes and Integrates Corn-Based Product Lines

The Corn Wet Milling Plant Processing Equipment from VetterTec delivers a fully integrated solution for handling various corn-based products. This equipment excels in pre-concentration, dewatering, drying, and pelletizing operations with advanced systems like spray, tube bundle, and ring dryers. It’s ideal for creating high-demand end-products such as corn syrup, ethanol fuel, and protein powders, capable of processing large volumes continuously at high speed. With PLC automation and options for stainless steel construction, the equipment ensures efficient, energy-saving operations and superior integration into existing production lines. Maintenance is simplified with its CIP-ready design, adhering to industry safety standards and regulations, while offering customization options for specific process needs.

Benefits

- Enhances production efficiency with continuous high-speed processing.

- Reduces energy usage up to 20% with optimized drying systems.

- Simplifies integration with existing processes through flexible configuration.

- Decreases operational costs by reducing manual interventions with PLC automation.

- Supports environmental compliance with minimized emissions technology.

- Applications

- Corn products, Starch products, Animal feed, Bioethanol, Plant-based proteins, Corn gluten, Corn germ, Maltodextrin, Potable alcohol

- End products

- Modified starch, Corn protein isolates, Protein powders, Cornstarch, Whiskey, Ethanol fuel, Corn gluten meal, High-fructose corn syrup, Cattle feed, Poultry feed, Maltodextrin powder, Dextrose, Corn syrup, Vodka, Corn germ oil

- Steps before

- Corn steep liquor pre-concentration, Corn germ dewatering, Corn fiber dewatering, Corn starch dewatering

- Steps after

- Corn germ drying, Corn feed drying, Corn starch drying, Corn starch milling, Corn feed pelletizing, Packaging in sacks and big bags

- Input ingredients

- corn, corn steep liquor (CSL), corn germ, corn fiber, corn starch, corn gluten

- Output ingredients

- pre-concentrated corn steep liquor, dewatered corn germ, dried corn germ, dewatered corn fiber, dried corn feed (fibers and CSL), corn feed pellets, dewatered corn starch, dried corn starch, maltodextrin, dried corn gluten

- Market info

- VetterTec is known for engineering and manufacturing industrial drying and dewatering solutions, particularly for the food, brewery, chemical, and environmental industries, leveraging extensive experience in delivering efficient and reliable tailored systems.

- Energy recovery

- Yes (CSL pre-concentration)

- Dewatering technologies

- Germ, fiber, starch

- Drying technologies

- Germ, fiber, feed, starch, gluten

- Pelletizing capability

- Feed

- Milling capability

- Starch

- Spray drying

- Maltodextrin

- Pneumatic conveying

- Available

- Integrated packaging

- Sacks and big bags

- Emission control

- Closed air system

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat sensitivity

- High

- Viscosity

- High / Low

- Foaming

- Yes/No

- Container size and shape

- Sacks / Big bags

- Starch type

- Native / Modified

- Pelletizing

- Required

- Control panel type

- HMI / Touchscreen / SCADA

- Pneumatic conveying system

- Customizable paths and specs

- Integrated packing system

- Custom sack and bag sizes

- Pelletizer configuration

- Custom feed rate/output size

- Energy recovery evaporator

- Custom temperature recovery

- Dryer system type

- Germ / Feed / Starch custom options