Premade pouch fill and seal solution

Effortlessly fill and seal various pouch sizes for streamlined packaging in diverse food, beverage, and health product lines, ensuring high speed and precision.

Fills and Seals Premade Pouches

The Viking-8S-235 from Viking Masek is a rotary premade pouch fill and seal machine designed to streamline packaging operations. It utilizes a servo-driven, multi-station rotary platform, offering a seamless production process that includes filling, sealing, deflation, and quality control. With speeds of up to 60 bags per minute, this machine supports a range of products from food and beverages to medical supplies. Its advanced PLC control system ensures precise automation, while features like pouch presence detection and an automatic deoxidizer feeding station enhance operational efficiency. The machine is adaptable for various pouch sizes and materials, supported by a highly durable welded steel frame. Equipped with an energy-efficient motor and cooling station for liquid products, it integrates effortlessly into existing production lines. Options for customization, including product-specific filling systems and advanced quality inspection tools, make it a versatile choice for contract packaging and diverse manufacturing industries.

Benefits

- Boosts production efficiency with high-speed operation, achieving up to 60 cycles per minute.

- Ensures product integrity with precise filling and sealing, minimizing waste and defects.

- Lowers energy costs through optimized motor control and efficient process integration.

- Adaptable to various product types and sizes, enhancing flexibility in manufacturing lines.

- Enhances safety and compliance with interlocked guards and comprehensive quality control systems.

- Applications

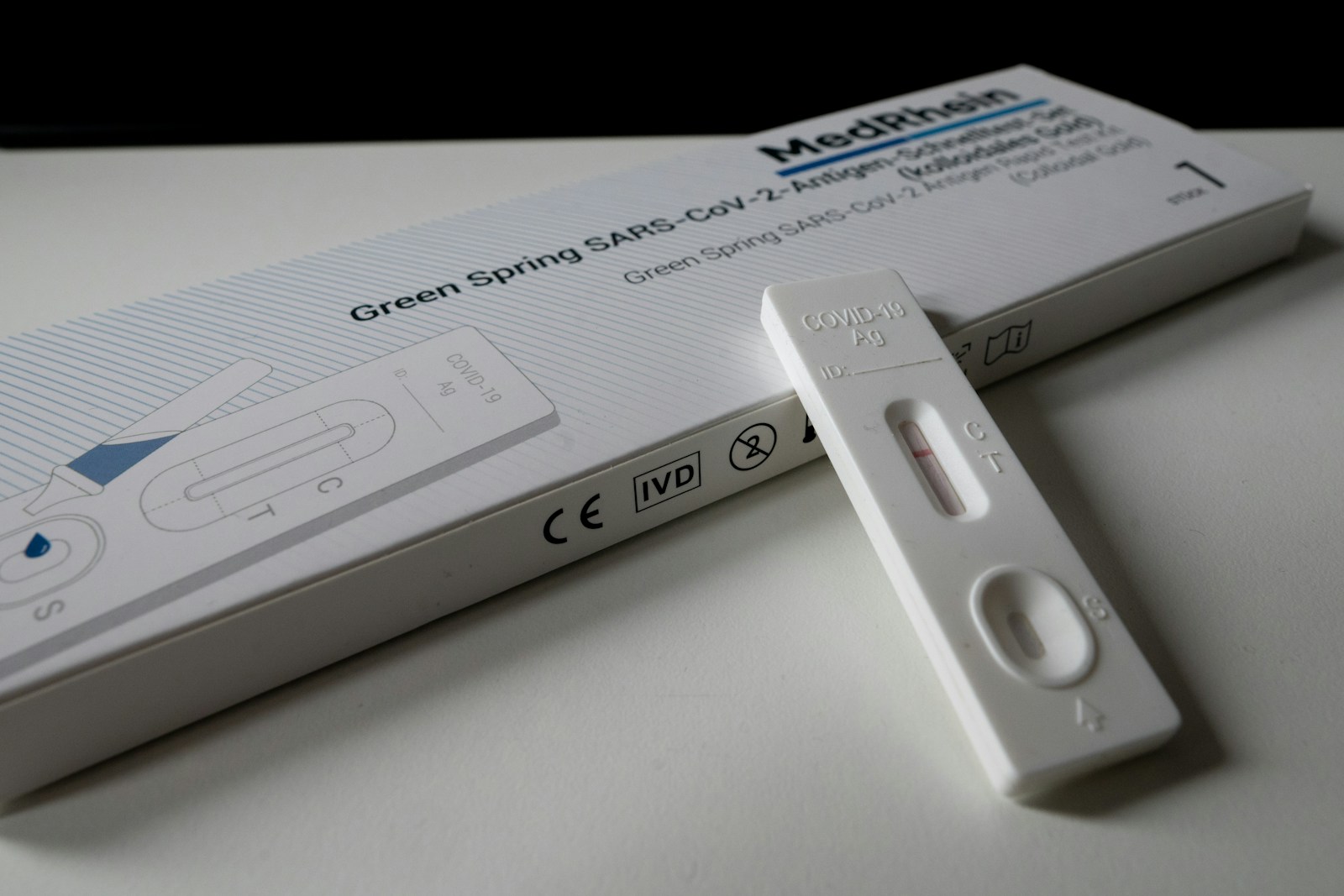

- Treats, Medical devices, Snacks, Cheese, Medical testing kits, Fish, Liquids, Fresh fruit, Beans, Supplies, Pills, Cannabis, Capsules, Powders, Candy, Pasta, Pet food, Individual quick frozen (iqf), Nuts, Natural, Rice, Cereal, Meat, Coffee, Vegetables, Poultry, Organic foods

- End products

- Dog kibble, Bottled water, Chicken fillets, Salmon portions, Protein powder, Cannabidiol oil, Pistachios, Spaghetti noodles, Jasmine rice, Granola bars, Frozen peas, Organic quinoa, Coffee beans, Covid-19 test kits, Mixed fruit packs, Ground beef, Surgical masks, Black beans, Cat treats, Cheddar cheese cubes, Gumballs, Vitamin capsules

- Steps before

- Gripper size setting, Machine speed configuration, Sealing temperature adjustment, Filling volume setup, Pouch presence detection

- Steps after

- Quality control, Cooling, Pouch discharge, Date coding, Bag rejection

- Input ingredients

- STANDCAP pouches, bags, liquid products, rice, powders, precooked meat, candy, gumballs, pistachios, nuts, volumetric fillers, auger fillers

- Output ingredients

- filled and sealed premade pouches, filled and sealed STANDCAP pouches, packaged rice, packaged powders, packaged precooked meat, packaged candy, packaged gumballs, packaged pistachios, packaged nuts

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Maximum Speed

- 60 bpm

- Bag Size

- Min 90 mm W x 120 mm L, Max 235 mm W x 350 mm L

- Number of Stations

- 8

- Bag Gripping Range

- 90-235 mm

- Maximum Bag Length

- 350 mm (500 mm with extender)

- Power Supply

- 480 V / 3 Ph / 60 Hz / 35 A

- Compressed Air

- Approx. 600 NL/min, 5~6 kgf/cm²

- Pouch Presence Detection

- No filling, no sealing

- Sealing Process

- Two-step sealing process

- Bag Deflation

- Wire guide or push bars

- Cooling Station

- For liquid products

- Automation

- PLC control with touch screen operation

- Control Platform

- Servo-driven Allen Bradley

- Material

- Highly durable welded steel frame

- Production Parameter Memory

- Yes, including gripper size, machine speed, sealing temperature, and filling volume

- Washdown Structure

- IP65 or IP66

- Bag Rejection System

- Yes

- Cooling Medium

- Steam or gas flush

- Working Mechanism

- Automatic Rotary

- Integrated Steps

- Fill and Seal

- Batch vs. Continuous Operation

- Continuous

- Automation Level

- PLC-controlled

- Control Interface

- Touch Screen

- CIP/SIP

- Clean-in-place design

- Changeover Time

- Efficient with production parameter memory

- Sealing Method

- Two-step sealing process

- Pouch Presence Detection

- No filling, No sealing

- Cooling Station

- Available for liquid products

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size and shape

- Min 90 mm W x 120 mm L, Max 235 mm W x 350 mm L

- Bag type

- Premade Pouch, STANDCAP

- Product type

- Food, Beverage, Liquids, Powders, Candy, Nuts, Pet Food

- Heat sensitivity

- Pouch presence detection, Cooling station for liquid products

- Machine footprint

- Depends on configuration, typically compact

- Bag width range

- 90 mm to 235 mm

- Bag length range

- 120 mm to 350 mm

- Control panel type

- PLC control with touch screen operation

- Frame material

- Highly durable welded steel

- Operating speed

- Up to 60 bpm

- Number of stations

- 8 stations, single bag

- Discharge method

- Stand-up discharge

- Bag gripping range

- 90-235 mm

- Compressed air requirements

- Approx. 600 NL/min, 5~6 kgf/cm²

- Control panel type

- PLC control with touch screen operation

- Integration possibilities

- Integrated with multi-head scales, volumetric and auger fillers

- Additional features

- Ethernet connectivity, washdown structure, steam or gas flush

- Bag support

- Bag supporter for heavy fills

- Gripper size memory

- Gripper size memory for production parameters

- Cooling system

- Cooling station for liquid products

- Pouch presence detection

- No filling, no sealing

- Sealing process

- Two step sealing guarantees clean sealing

- Quality control features

- Checkweigher, metal detector, X-ray inspection

- Deoxidizer feeding

- Automatic deoxidizer feeding station

- Presealing for liquids

- Presealing station for liquid or paste

- Dust management

- Dust suction nozzles and dust collector

- Date coding

- Emboss, hot stamp, inkjet or thermal transfer

- Robotic system

- Viking proprietary robotic pick, place bag infeed system