Vacuum drum filter for solid/liquid separation

Optimize your solid/liquid separation process with a versatile vacuum drum filter designed to handle challenging filtration, washing, and drying tasks in continuous operation.

Filters and Separates Solids from Liquids

The Krauss-Maffei vacuum drum filter TSF from ANDRITZ SEPARATION efficiently tackles solid/liquid separation challenges across various industries. This equipment excels with its continuous filtration process, utilizing submersible drum technology and a vacuum system to separate solids from liquids effectively. It’s particularly suited for applications in chemical manufacturing, mining, food processing, and wastewater treatment, producing outputs such as ABS resins, aluminum hydroxide powders, and vitamin additives.

With a filtration capacity ranging from 100 to 2,000 l/m²h and solids throughput up to 1,500 kg/m²h, this machine is engineered for high-speed, continuous operation. The Krauss-Maffei TSF integrates seamlessly into existing production lines, equipped with PLC-controlled systems for precise automation and adaptable differential pressures for each filtration zone. Energy consumption is minimized through variable operation pressures, and it offers reduced operating costs due to its maintenance-friendly design.

Available in various construction materials, including stainless steel, it handles corrosive materials with ease. The filter meets ATEX requirements for safe processing in explosive environments. For upkeep, the maintenance-friendly design allows easy access to components, while its CIP (Clean-In-Place) system ensures quick and thorough cleaning. Installation can be customized to match your specific production needs, supported by ANDRITZ’s engineering expertise.

Benefits

- Enhances process efficiency by optimizing hydraulic performance for increased filtration capacity.

- Lower energy usage results in significant operational savings and environmental benefits.

- Flexible adaptation to various filtration pressures improves product quality across different applications.

- Simplifies maintenance with easy access and inspection points, reducing downtime.

- Designed for ATEX compliance, ensuring safe operations in explosive and hazardous environments.

- Applications

- Chemicals, Industrial wastewater, Pharmaceuticals, Fine chemicals, Food ingredients, Mining and minerals, Municipal wastewater, Environmental applications

- End products

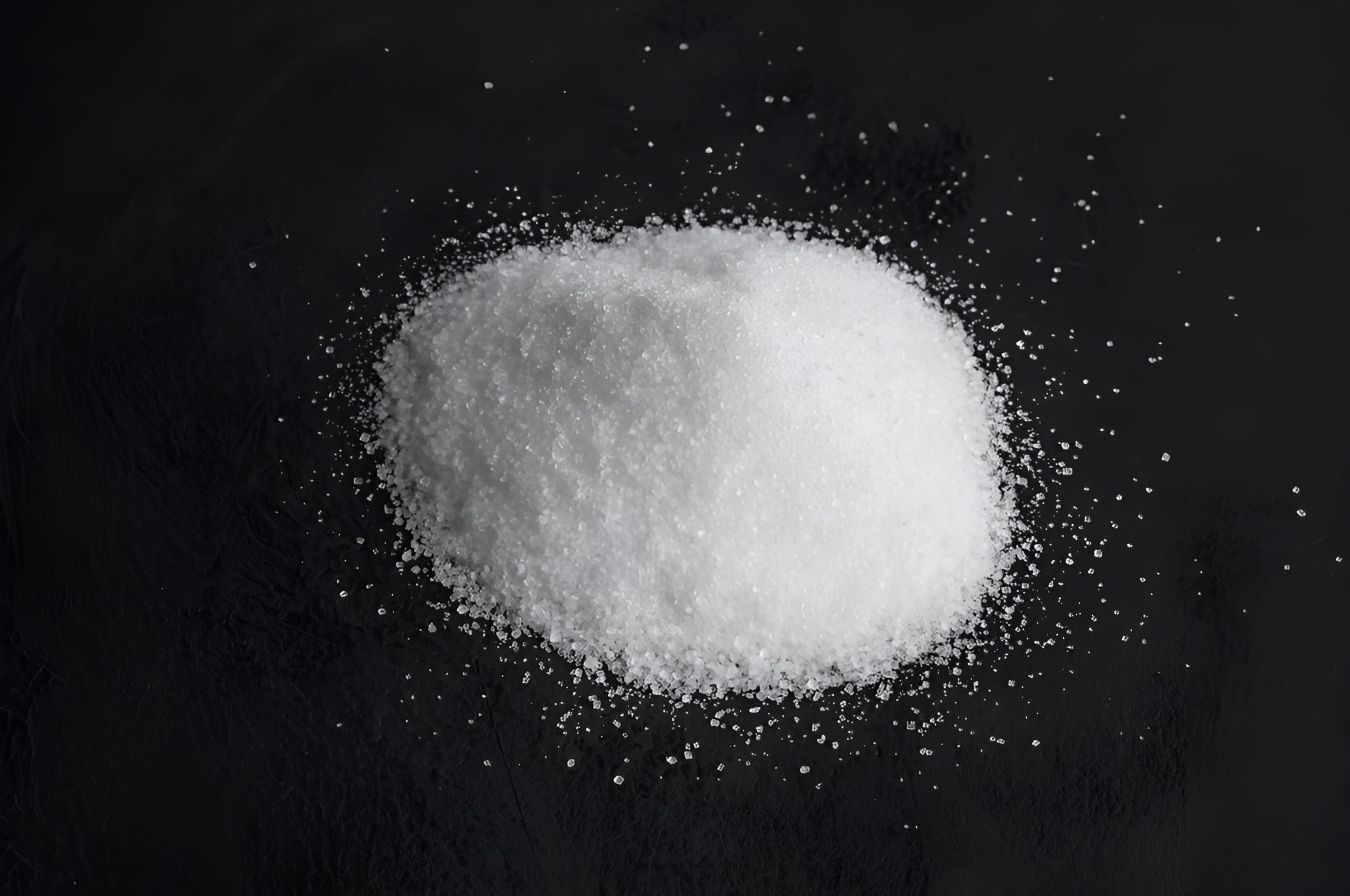

- Aluminum hydroxide powder, Red mud wastes, Phosphate fertilizers, Edible oils, Gypsum plaster, Abs resin, Baking soda, Starch derivatives, Soda ash, Plastic intermediate compounds, Titanium dioxide pigments, Copper concentrate, Sugar syrups, Cellulose derivatives, Bisphenol a (bpa), Citric acid powder, Aluminum processing residues, Protein isolates, Sulfate salts, Methyl methacrylate-butadiene-styrene (mbs) polymer, Vitamin additives, Synthetic indigo dyes, Carbonate salts, Caffeine extracts, Sludge cakes, Potash sludge, Lead carbonate pigments, Insecticide formulations, Pectin gel, Fungal mycelium extracts, Dye powders, Antibiotic compounds, Melamine powder, Sodium alginate gels, Iron ore concentrate, Cryolite material, Herbicide granules

- Steps before

- Slurry Preparation, Homogeneous Mixing, Particle Size Reduction

- Steps after

- Washing, Drying, Cake Discharge, Transport of Solids, Further Processing

- Input ingredients

- suspension, slurry, chemicals, industrial wastewater, municipal wastewater, food substances, flotation concentrate, minerals, particles

- Output ingredients

- filter cake, clear filtrate, washed solids, dried solids, discharged solids

- Market info

- ANDRITZ is known for its expertise in supplying industrial ETO equipment and services, specializing in sectors like pulp and paper, hydropower, and metals. It has a strong reputation for innovation and engineering excellence.

- Filtration capacity

- 100–2, 000 l/m²h

- Solids throughput

- up to 1, 500 kg/m²h

- Pressure operation

- up to 70 mbar

- Operating temperature

- up to 95 °C

- Drum rotation speed

- up to 4 rpm

- Average particle size

- 1–300 µm

- Drive power requirements

- 2.0–11.0 kW

- Drum diameter

- 920–7, 500 mm

- Drum width

- 250–9, 000 mm

- Number of cells

- 14–32

- Working mechanism

- Continuous rotary vacuum drum

- Filtration process

- Solid/liquid separation

- Filtration zones

- Multiple stages including washing and drying

- Integrated discharge system

- Adaptive to cake consistency

- Automation level

- Manual / PLC

- Cleaning method

- Water jets/bubbles for filter cloth

- Batch vs. continuous operation

- Continuous

- Energy efficiency

- Low energy consumption

- Sedimentation prevention

- Pendulum agitator

- ATEX compliance

- Yes

- Gas-tight designs

- Available

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 1-300 µm

- Filtration type

- Vacuum drum filter

- Gas-tight design

- Yes

- Machine footprint

- Variable based on model

- Drum diameter

- 920–7, 500 mm

- Drum width

- 250–9, 000 mm

- Number of cells

- 14–32

- Weight

- 1, 500–68, 000 kg

- Drive power

- 1.5–11.0 kW

- Discharge method

- Scraper, roller, pre-coat scraper, string or belt discharge

- Construction materials

- Various

- Discharge system

- Product-adaptive

- Drum width

- 250-9, 000 mm

- Pressure operation

- Up to 70 mbar

- Operating temperature

- Up to 95 °C

- Conveyor adaptation for solids transport

- Screw or belt conveyors, chutes

- Control systems

- Metris addIQ

- Gas-tight designs

- Available

- Multi-stage counter-current washing

- Available